MAINTENANCE AND SERVICING

Hoses and Lines

Check hydraulic hoses and lines daily for signs of leaks.

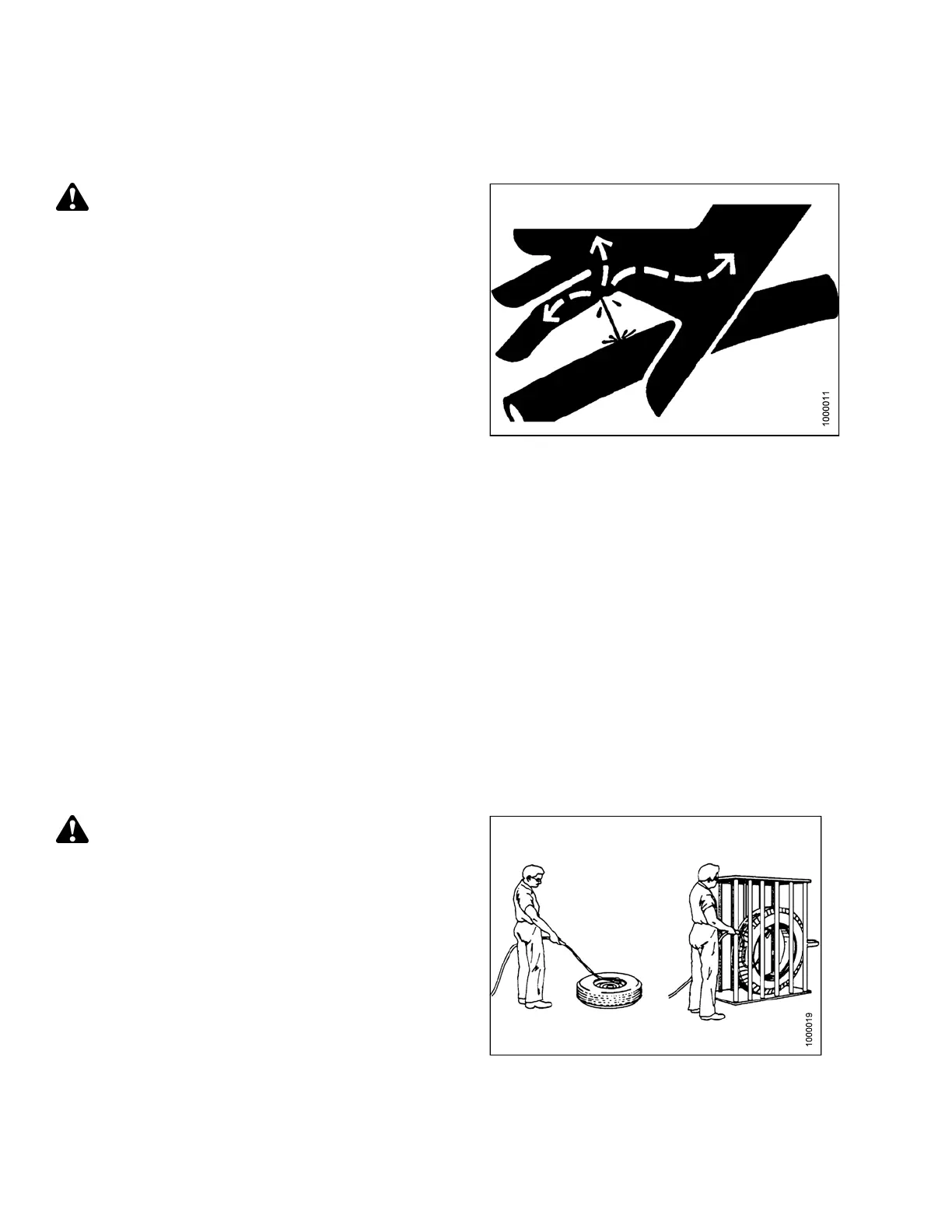

WARNING

• Avoid high-pressure fluids. Escaping fluid can

penetrate the skin c ausing serious injury.

• R elieve pressure before disconnecting

hydraulic lines. Tighten all connections before

applying pressure.

• K eep hands and body away from pin-holes and

nozzles which eject fluids under high pressure.

• If ANY fluid is injected into the skin, it must

be surgically removed within a few hours by a

Doctor familiar with this type of injury or gangrene

may result.

• U se a piece of cardboard or paper to search

for leaks.

Figure 5.190: Hydraulic Pressure Hazard

IMPORTANT:

• Keep hydraulic coupler tips and connectors clean.

Dust, dirt, water, and foreign material are the major

causes of hydraulic system damage.

•DONOT attempt to service hydraulic system in the

field. Precision fits require WHITE ROOM CARE during

overhaul.

5.7.10 Wheels and Tires

Drive Wheel

Inflating Drive Wheel Tire

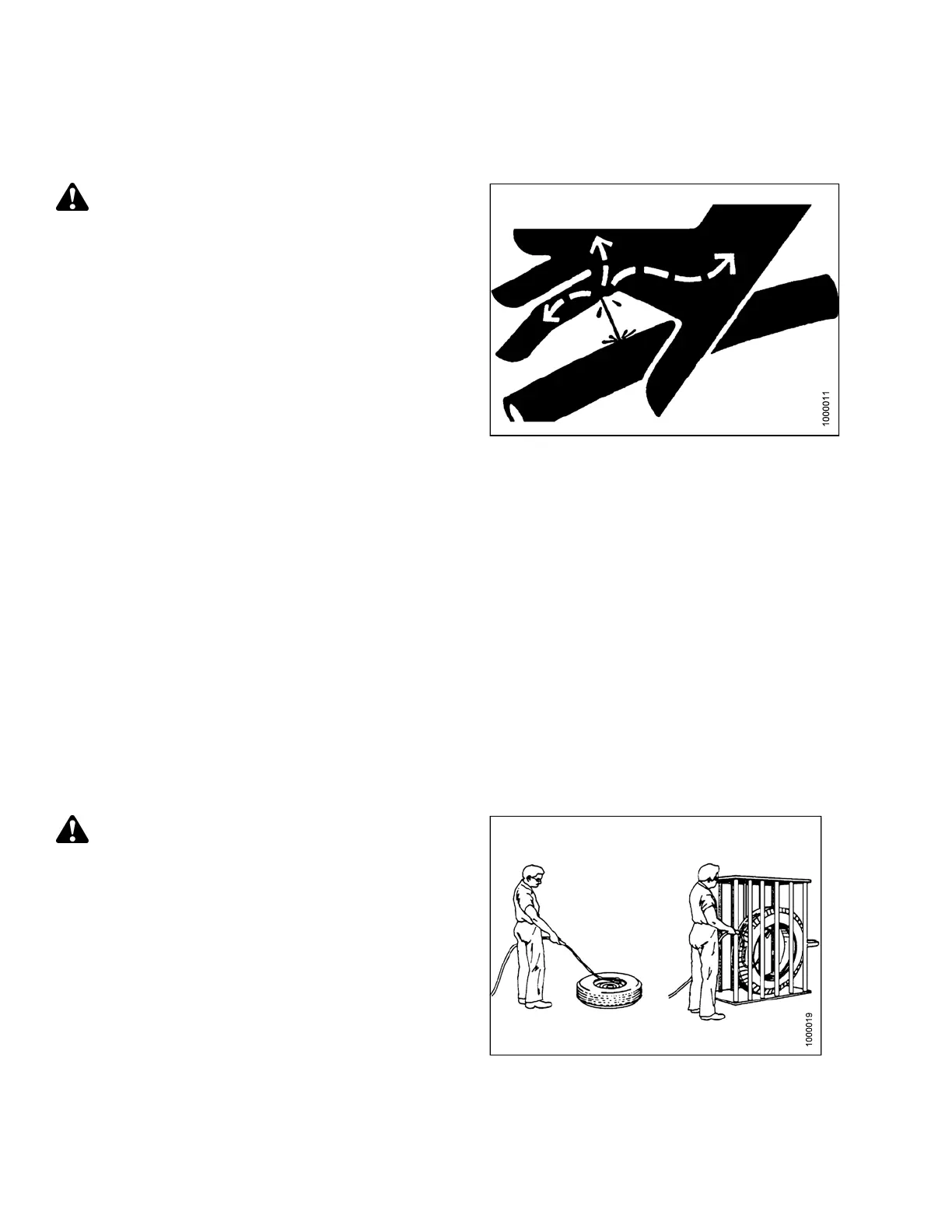

DANGER

• Use a safety cag e if availab l e.

• D o NOT stand over tire. Use a clip-on chuck and

extension hose.

• N EVER install a tube in a cracked wheel rim.

• NEVER weld a wheel rim.

• D o NOT exceed maximum inflation pressure as per

label on tire.

• M ake sure all the air is rem oved from a tire before

removing the tire from the rim.

Figure 5.191: Drive Tire Inflatio n

169890 298 Revision A

Loading...

Loading...