OPERATION

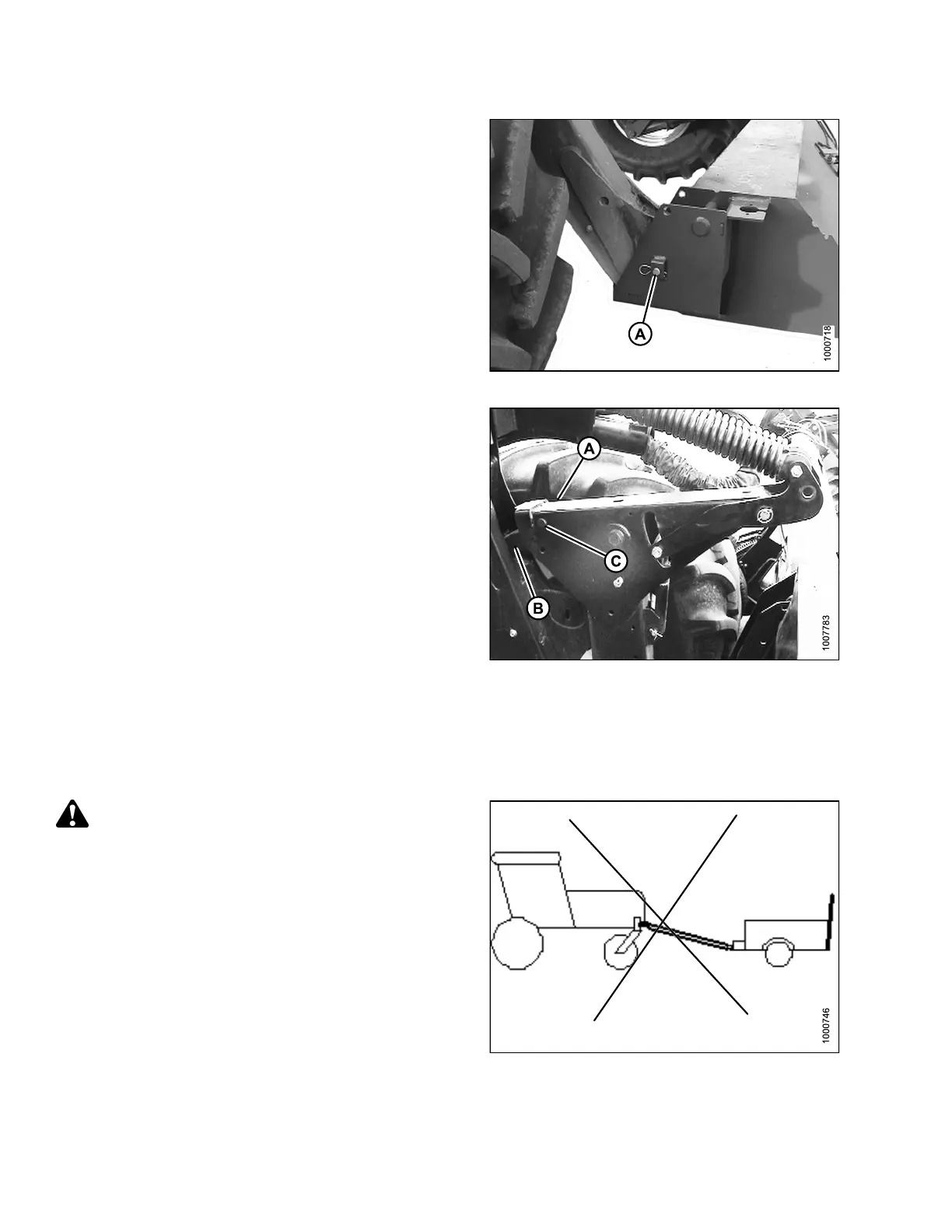

9. Remove pins (A) securing lift linkages to weight box,

and retain p ins for attaching header to windrower.

10. Start engine, lower weight box onto blocks, and

back away.

11. Attach header to windrower. Refer to 4.5.1 Attaching a

D-Series Header, page 131.

12. Convert header to field position. Refer to header

operator’s manual for procedure.

Figure 4.54: Weight Box

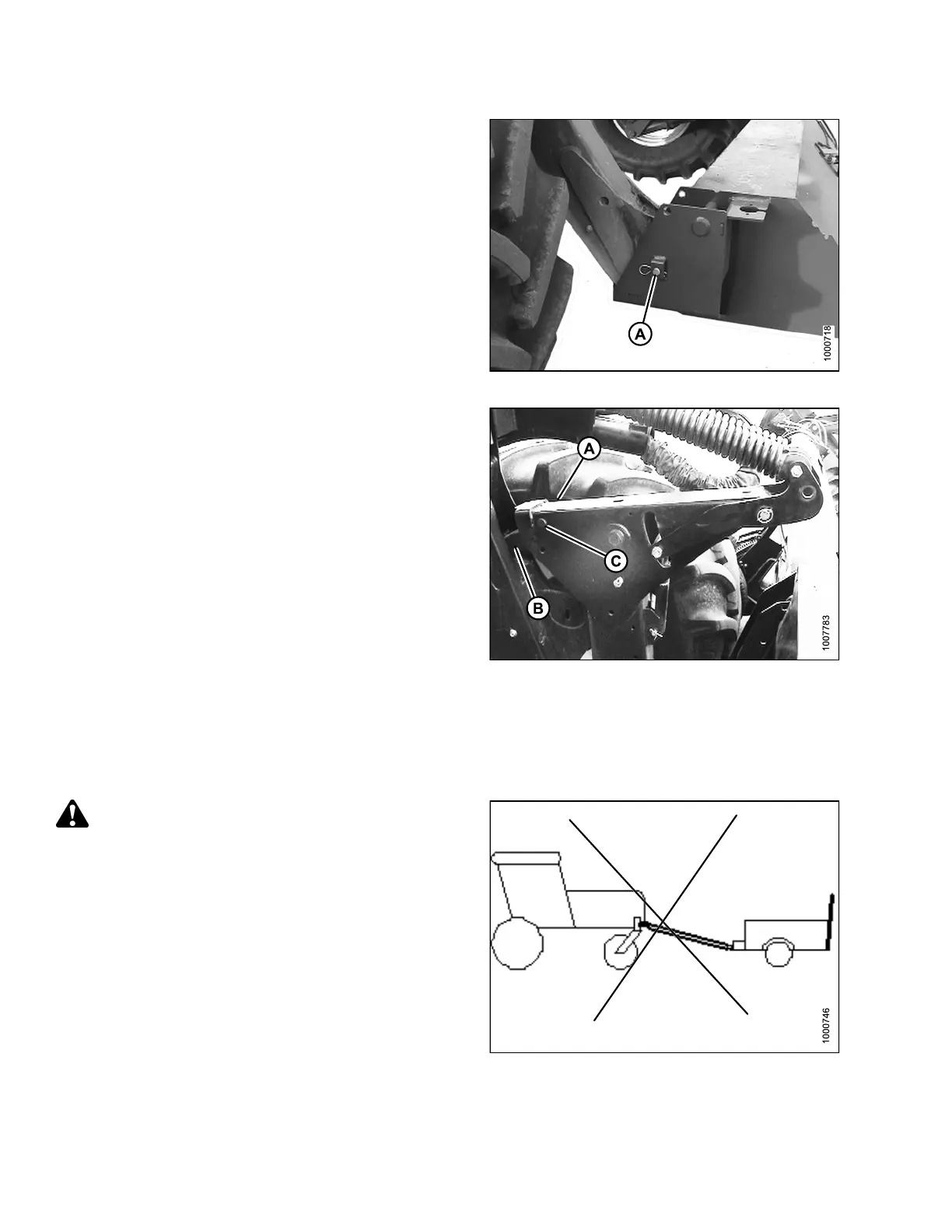

13. Start engine, and lower header to ground. Continue to

retract lift c ylinders so that member (A) lifts off link (B).

14. Remove temporary lift pins (C) from lift arms, and

install pins into storage holes in weight box.

15. Before operating the machine, double check that

all pins are secure , and that all saf ety equipment is

installed and fully functional.

16. Proceed to operate the header.

Figure 4.55: Lift Arms

Towing the Windrower (Emergency)

In emer

gency situations, for example, towing out of a field or into a shop, windrower may be towed without a

traile

r, providing the following precautions are followed:

WARNING

A proper towing apparatus is critical to safe towing.

Use the following gu idelines:

• Do NOT attach d irec t ly from hitch to walking beam .

Slope of tow-bar will not provide proper transfer of

braking force to windrower, causing loss of control.

• For proper steering, towing apparatus should

be attached to BOTH left and right hand frame

members, and should attach to tow-bar at same

height as towing vehicle hitch.

• Towing apparatus should be removed for field

operation, to avoid interference with windrow.

Fig

ure 4.56: Improper Towing Procedure

169890

1

14

Revision A

Loading...

Loading...