OPERATION

4.4.4 Header Drive

The headers ar

e hyd ra ulically driv en and controlle d from the windrower with no me chanical drive sha fts.

One hydraulic

piston pump on the windrower provides fluid power to the knife, and three gear pumps power the

drapers or a ug

er, reel, lift, and positioning systems and optional attachments.

All header co

ntrols are conveniently located on the operator’s console and on the ground speed lever (GSL) handle.

NOTE:

Some controls are optional equipment and may not be present in your unit. Some controls may be installed, but

will be nonfunctional for certain headers.

Engaging and Disengaging the Header

IMPORTANT

:

Always mov

e throttle lever back to idle before engaging header drive. D o NOT engage header with engine

at full rpm

.

CAUTION

Check to be sure all bystanders have cleared the area.

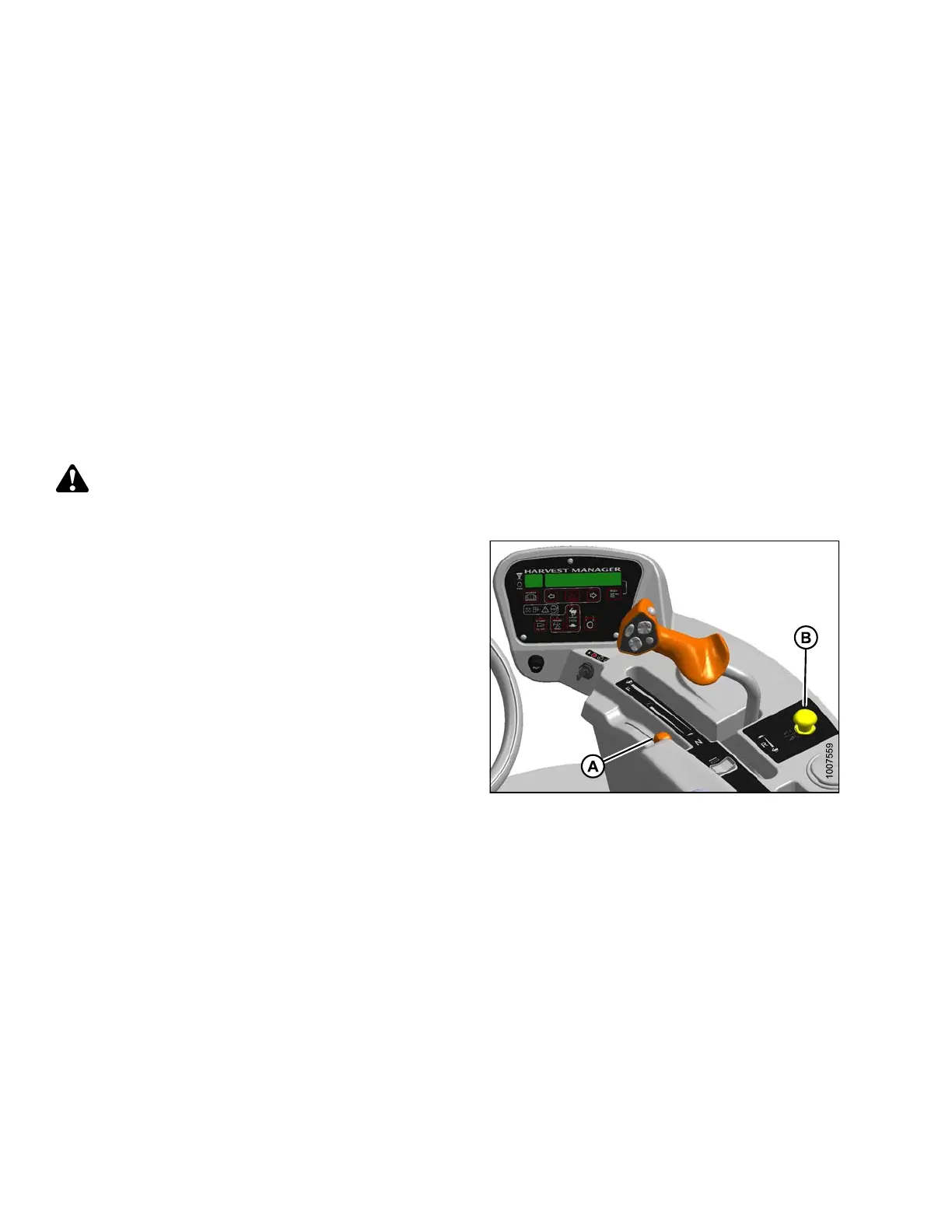

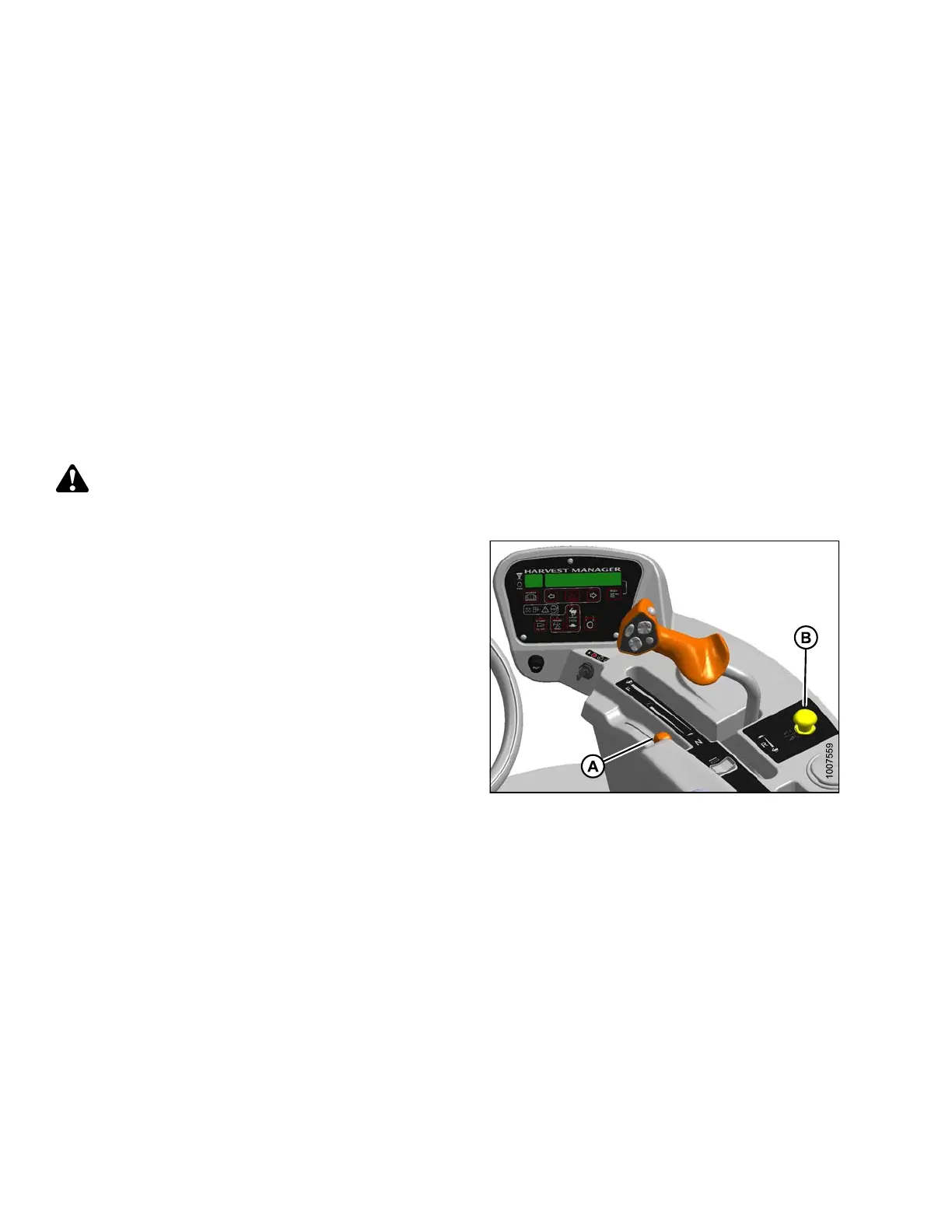

1. To Engage Header:

a. Move throttle (A) to adjus t engine speed to idle.

b. Push down on the yellow knob in the center of

the HEADER DRIVE switch (B) and pull up on the

black ring at the base of the switch. A slight delay

between switch ON and operating speed is normal.

2. To Disengage Header:

a. Push HEADER DRIVE switch (B) down to

disengage header drive.

Figure 4.70: Operator Console

4.4.5 Adjusting H eader Angle

Header angle is defined as the angle between the ground and the drapers/cutterbar and is adjustable to

accommodate crop conditions and/or soil type.

Refer to the appropriate header operator ’s manual for the range of adjustment and recommended settings for your

particular header.

The header angle can be hydraulically adjusted from the cab without shutting down the windrower. A readout on the

cab display module (CDM) allows you to establish settings for each crop condition. This feature requires that the

optional expansion module MD #B4666 be installed, either at the factory or at your MacDon Dealer.

169890

1

24

Revision A

Loading...

Loading...