MAINTENANCE AND SERVICING

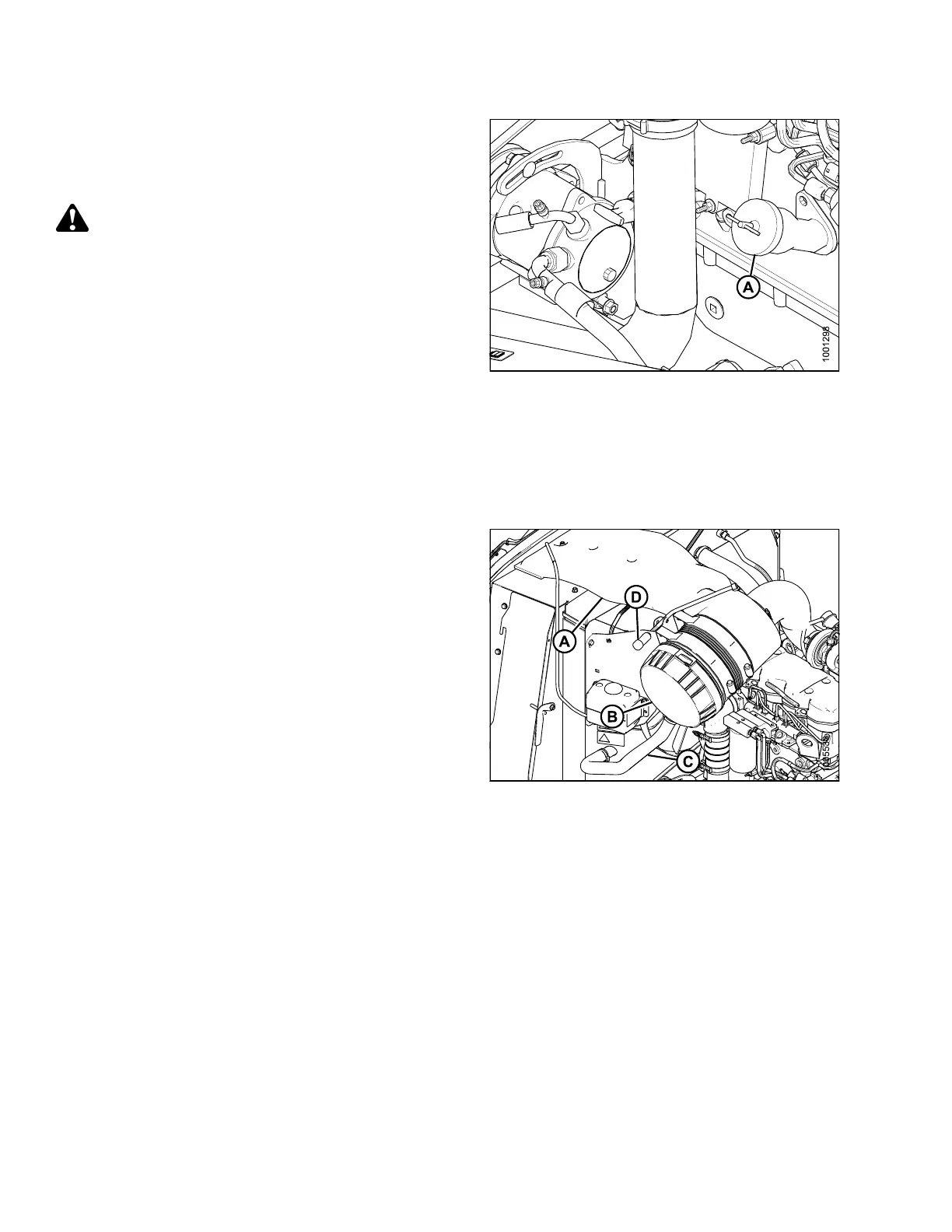

3. Remove filler c ap (A) by turning it counterclockwise.

4. Carefully pour the oil. A funnel is recommended to

avoid spillage. Refer to Lubricants, Fluids, and System

Capacities, pa ge 1 99 for oil spec ifications.

CAUTION

Do NOT fill above the HIGH mark.

5. Replace oil filler cap (A) and turn it clockwise until snug.

6. Check the oil level. Refer to Checkin g Engine Oil Level,

page 227.

7. Close the hood. Refer to 5.4.2 Closing Hood (Lower

Position), page 203.

Figure 5.64: Oil Filler Cap

Air Intake S ystem

IMPORTANT

:

Do NOT run e

ngine with air cleaner disconnected or disassembled.

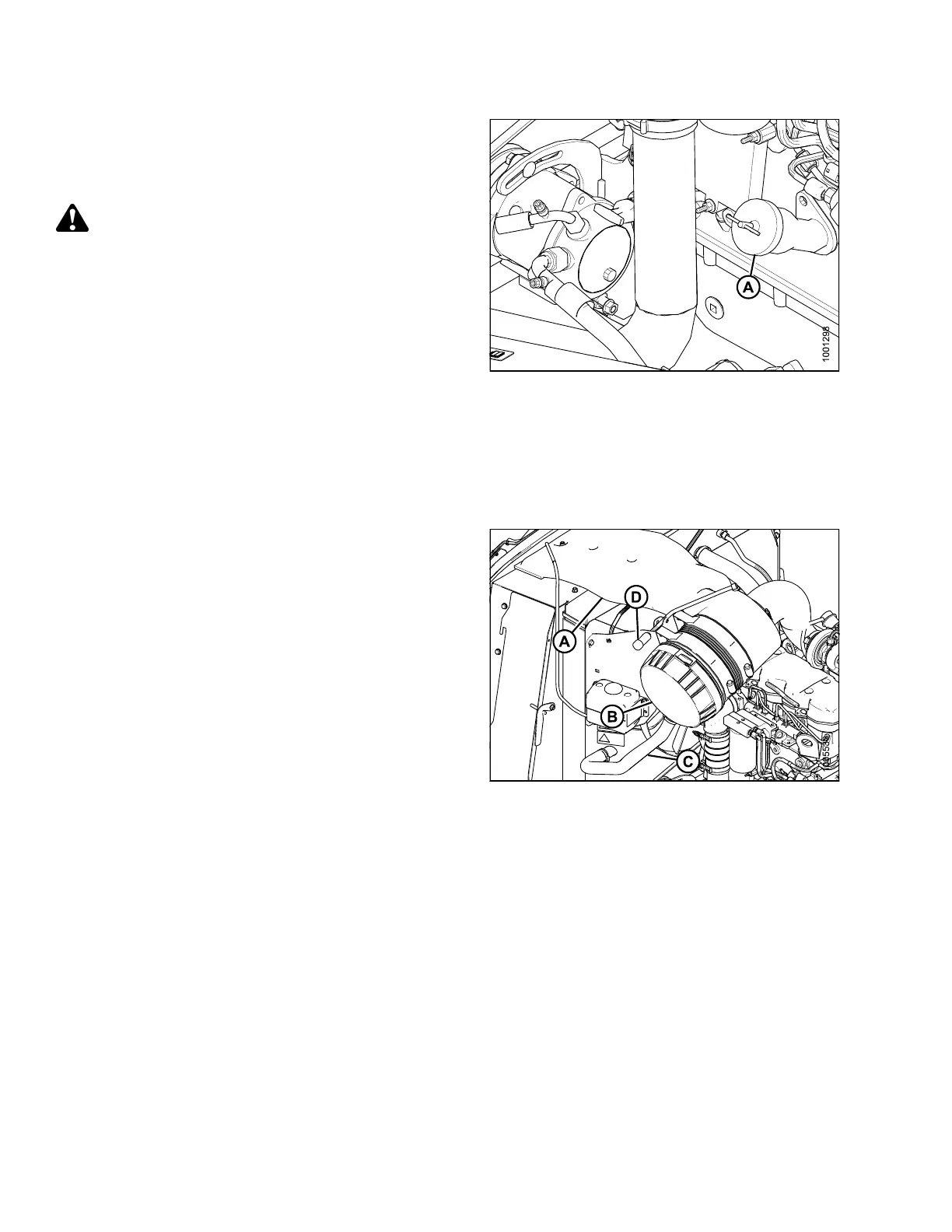

Engine intake air is drawn through a duct (A) from the

cooling box that precleans the air and then through a dual

element filter (B).

The air cleaner canister is equipped with an

aspirator (C) that removes dust continuously from the air

cleaner housing.

The air cleaner is also equipped with an air filter restriction

switch (D) that indicates when the prim ary filter elem ent

requires cleaning.

Refer to Filter Part Numbers, page 200.

Figure 5.65: Air Intake System

IMPORTANT:

•DoNOT run engine with air cleaner disconnected or

disassembled.

• Over-servicing the filter element increases the risk

of dirt being ingested by the engine and severely

damagin g the engine.

• Filter servicing should only be performed when

the CDM indicates “EN GINE AIR FILTER” or

at the specified interval. Refer to Maintenance

Schedule/Record, page 315.

169890 230 Revision A

Loading...

Loading...