OPERATION

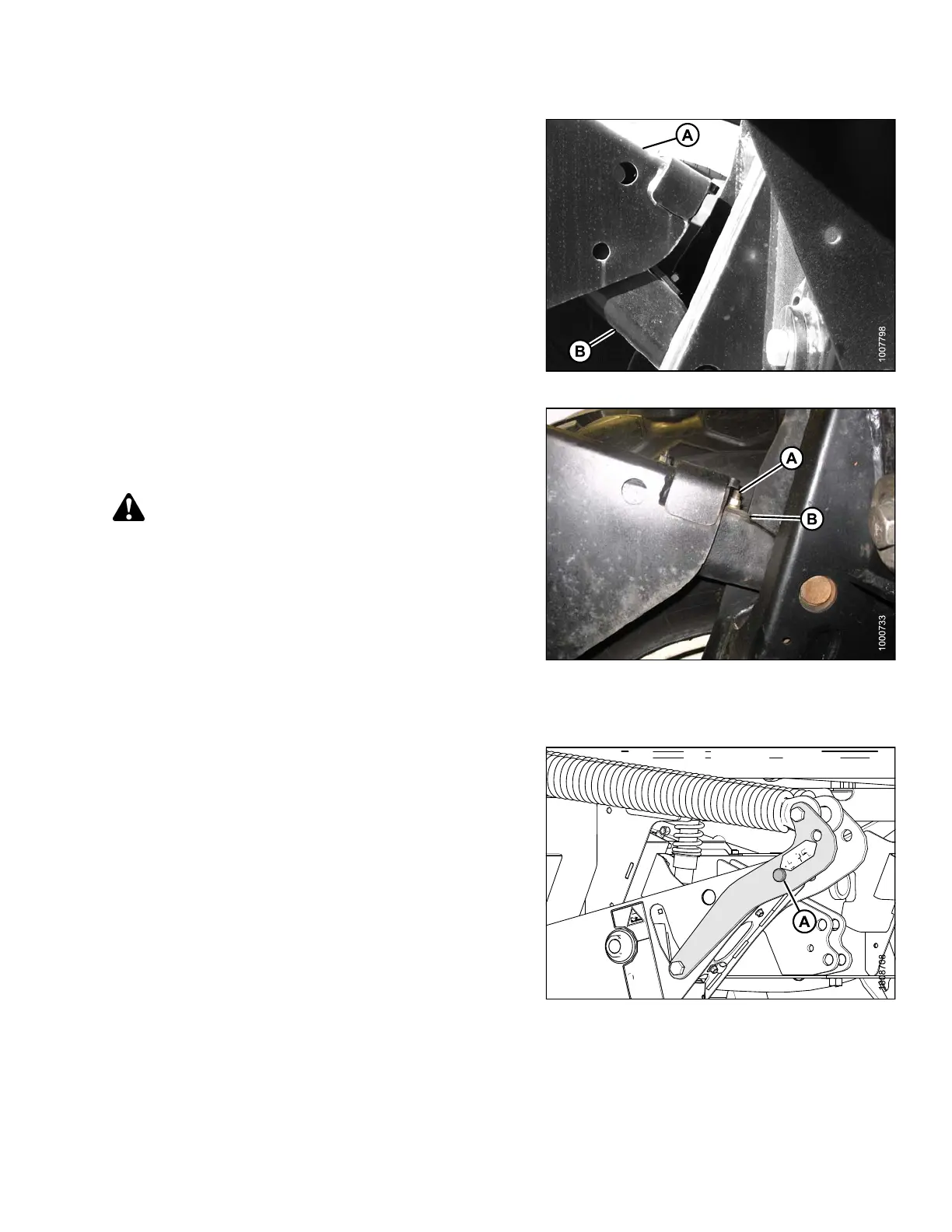

5. Lower header onto blocks so that member (A) lifts off

link (B) on both sides.

6. Stop engine and remove key.

Figure 4.67: Lift Linkage

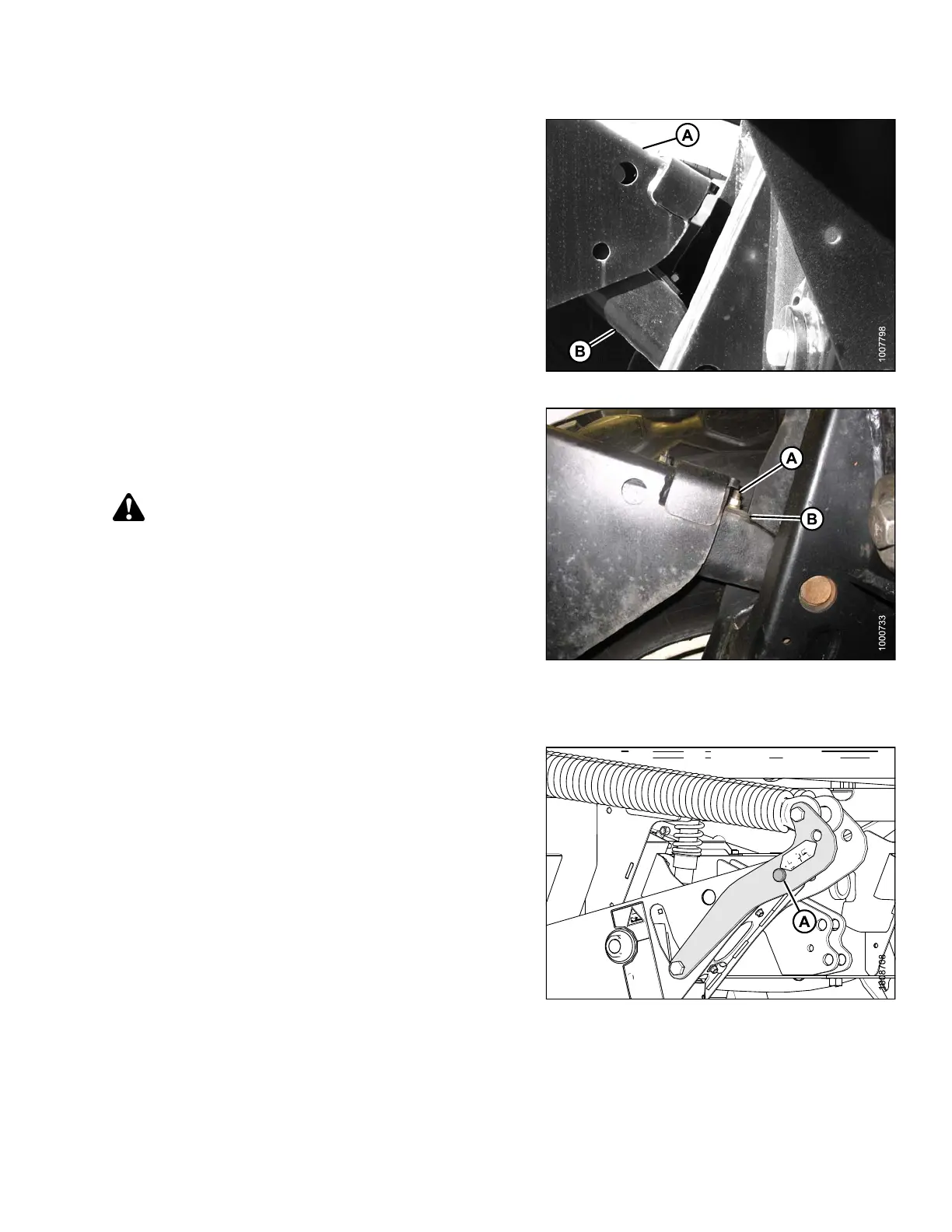

7. On high side, remove nut, washer, and bolt (A) that

attaches shims (B) to link.

8. Remove one or both shims (B) and reinstall the

hardware (A).

CAUTION

Check to be sure all bystanders have cleared the area.

9. Start engine and raise header slightly. Check level

of header.

10. If additional levelling is req uired, install the removed

shim on the opposite linkage.

NOTE:

If required, additional shims are available from your

Dealer.

Figure 4.68: Lift Linkage

11. Once header is level, return float pins to their engaged

position (A).

NOTE:

Float does NOT req uire adjustm ent after levelling header.

Figure 4.69: Float Pins

169890 123 Revision A

Loading...

Loading...