Vacuum spray degassing — 24.04.2020 - Rev. A

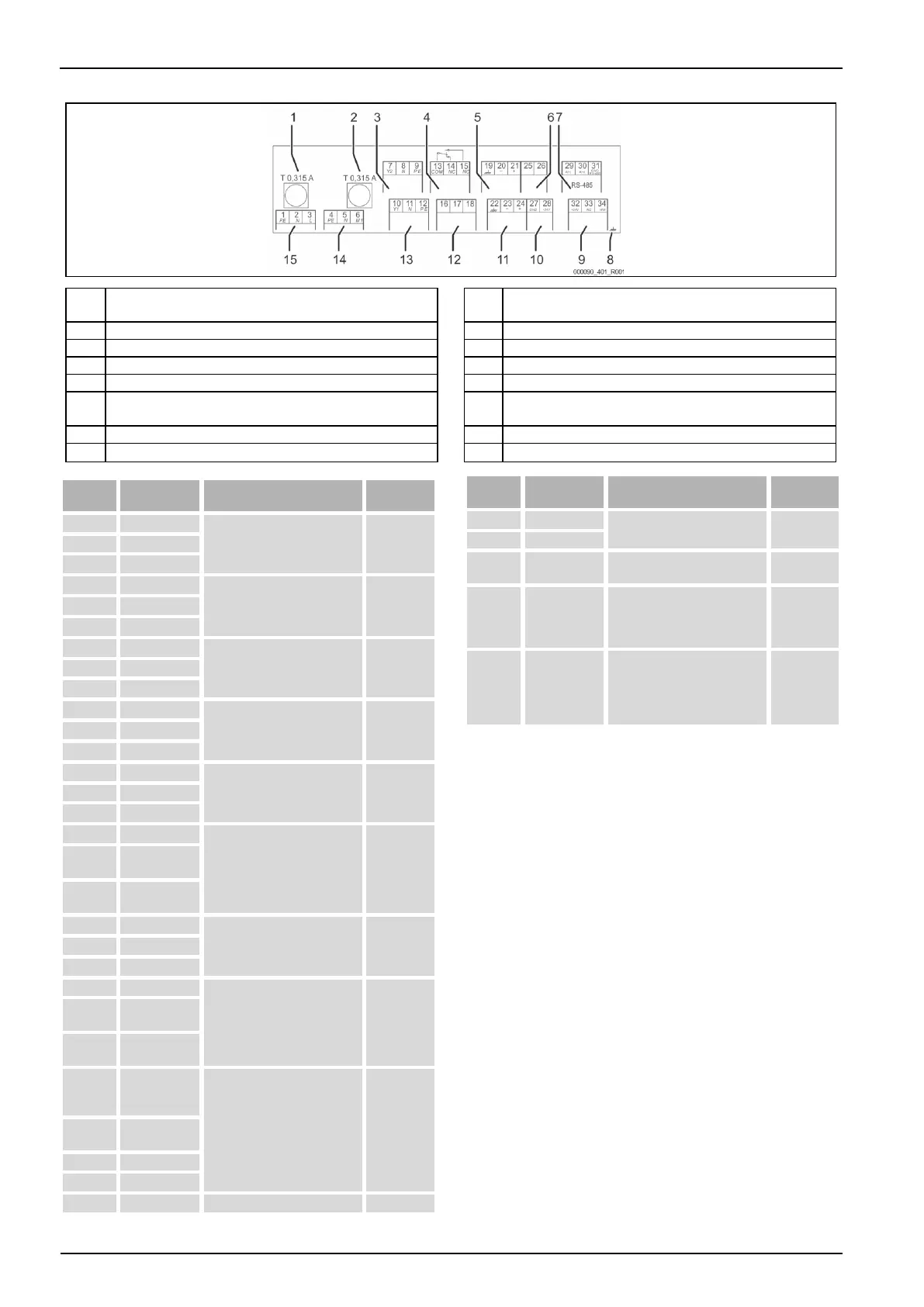

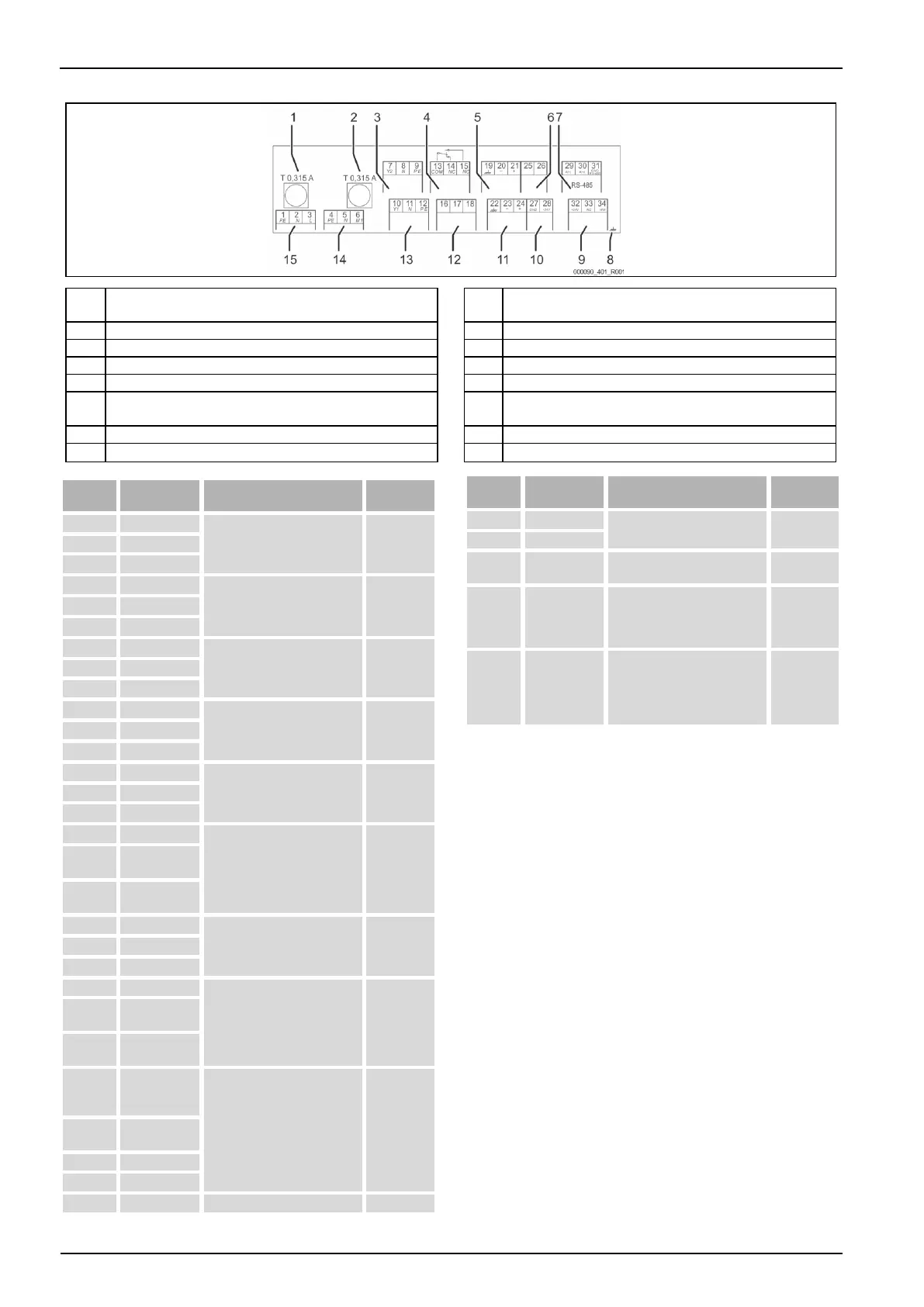

6.5.1 Terminal diagram

Digital inputs:

Water meter; Insufficient water

Fuse for motorized ball valve

Ball control valve (supply)

CD degassing control valve

External make-up demand (Levelcontrol only)

Optional for conductivity

Ball control valve

(correcting variable (25) / Return value (46))

230 V power supply via mains

cable and plug.

CD degassing control valve

Group message (floating).

External make-up demand from

a pressurisation station;

controller must be set to

"Levelcontrol"!

Level analogue input, not used

by the device.

0 – 10 V

(correcting

variable)

Insufficient water switch - dry-

running protection

Contact water meter, for

evaluation of the make-up,

terminal 32/33 closed = meter

pulse.

Insufficient water switch, contact

32/34. Lead the cable of the

insufficient water switch through

the cable gland and connect at

the terminals

6.5.2 RS-485 interface

6.5.2.1 Connecting the RS-485 interface

Connect the interface as follows:

1. For connecting the interface use only a cable with these properties:

– LJYCY (TP), 4 × 2 × 0.8, maximum overall bus length 1000 m.

2. Use a shielded cable to connect the interface to terminals 29, 30, 31 of the

main board in the control cabinet.

– For connecting the interface, see chapter 6.5 "Elektrischer Anschluss"

on page 10 .

3. When using the device with a control centre not supporting an RS-485

interface (RS-232, for example), you must use a corresponding adapter.

Loading...

Loading...