Section09PROPULSION

Subsection 02 (DRIVE SYSTEM)

F05I08A

1 2

TYPICAL

1. Alignment tool

2. Seal carrier

If alignment tool does not slide easily through seal

carrier, perform the alignment as follows.

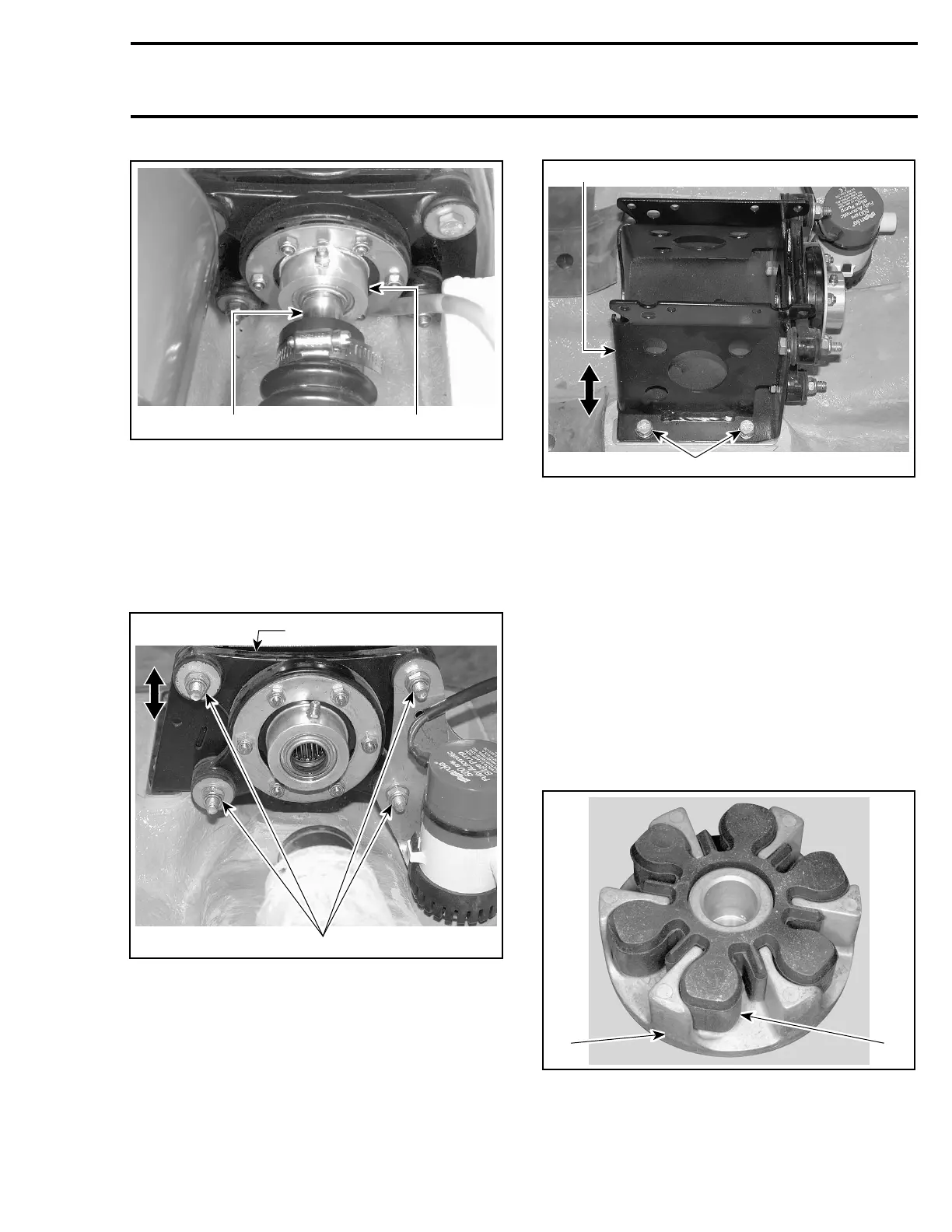

For vertical alignment, loosen damping support

nuts no. 27 and move the support no. 28 up and

down as necessary.

F00B25A

2

1

TYPICAL

1. Damping support

2. Loosen nuts

When done, ensure to apply Loctite 243 (blue)

(P/N 293 800 060) on nut threads then torque nuts

to 22 N•m(16lbf•ft) in a criss-cross sequence.

For horizontal alignment, loosen shaft support

screws no. 29 and move the support no. 15

sideways as necessary.

2

1

F00B26A

TYPICAL

1. Shaft support

2. Loosen screws on both sides

When done, ensure to apply Loctite 243 (blue)

(P/N 293 800 060) on screw threads then torque

screws to 22 N•m(16lbf•ft) in a criss-cross se-

quence.

NOTE: Ensure the alignment washers are still

loose.

Check engine alignment. Refer to ENGINE sec-

tion.

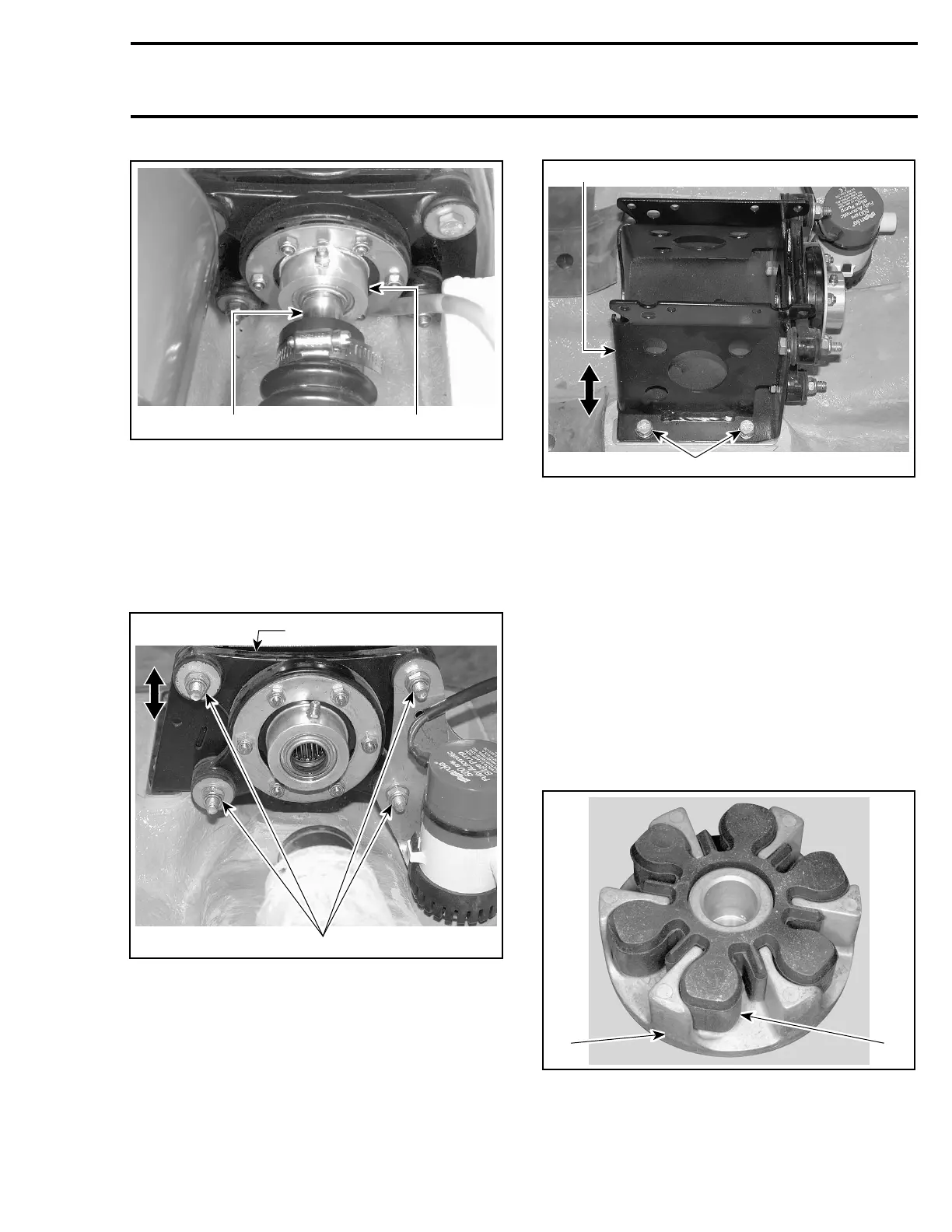

Front Drive Shaft Coupler and Damper

Make sure to install dampers no. 30 into drive

shaft coupler at both ends.

2

F08I07A

1

TYPICAL — SAME COUPLER AND DAMPER AT BOTH ENDS

1. Damper

2. Drive shaft coupler

smr2005-063 265

Loading...

Loading...