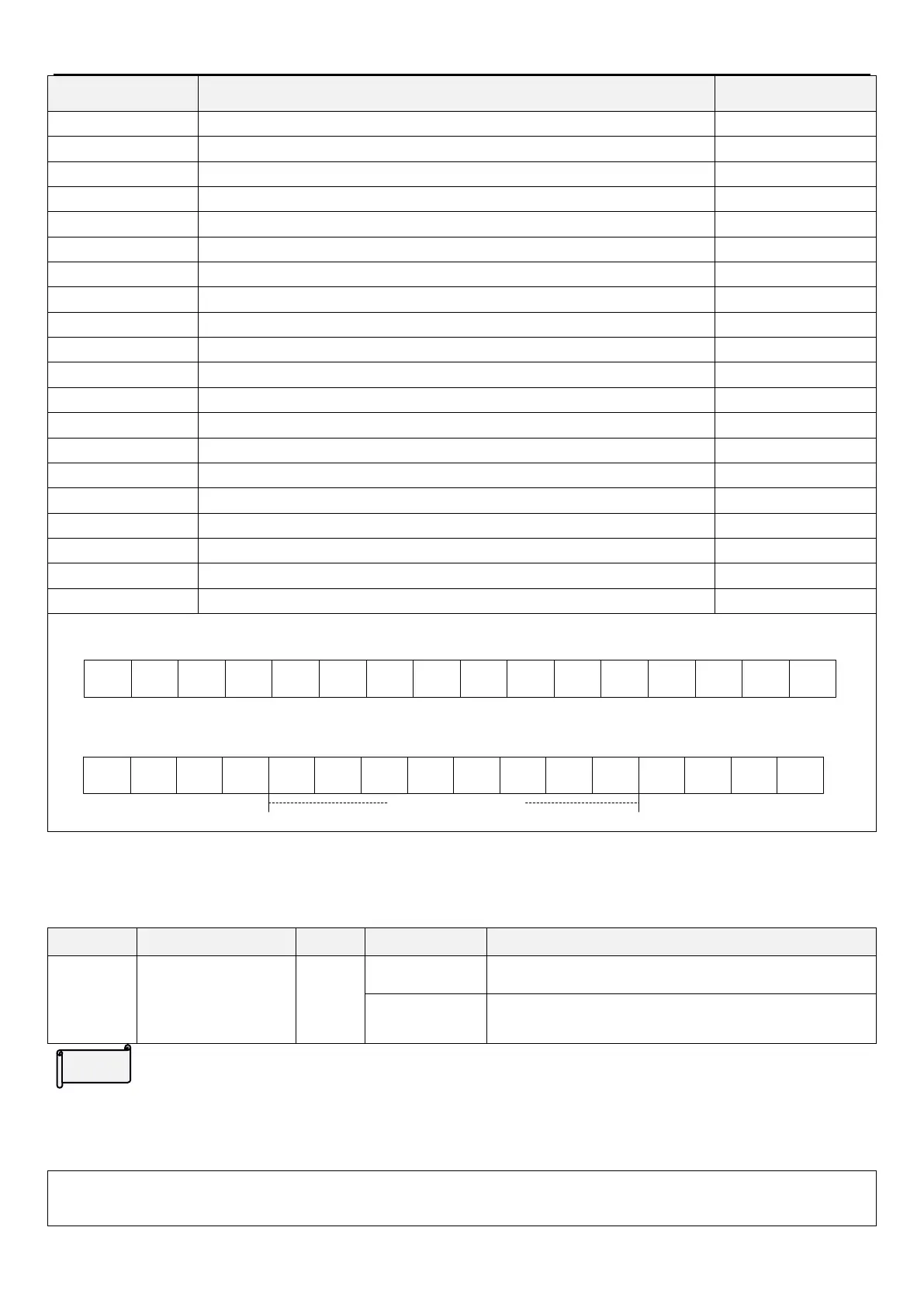

Communication parameter group07

PARAMETER DESCRIPTION 184

Inverter NTC temperature accumulation

Motor electronic thermal accumulation rate

PID control target pressure

PID control feedback pressure

Terminal HDI input frequency

Communication expansion card version number

Synchronous motor rotor pole position

Motor rotor position (Z phase is 0)

PG card A1B1 feedback pulse number

PG card A2B2 given number of pulses

Note: 1. Digital input terminal state details

b0

STFSTRM0M1M2RES

0

00

0

b1b2b3

b5

b6b7b8 b4b9

000000

b10b11b12b13b14b15

2. Digital output terminal state details

SO0 ABC

0

A10

A11

A12

A13A14

A15

A16A17

expanded

digital output

b0b1b2b3b5b6b7b8 b4b9

0000

b10b11b12b13b14b15

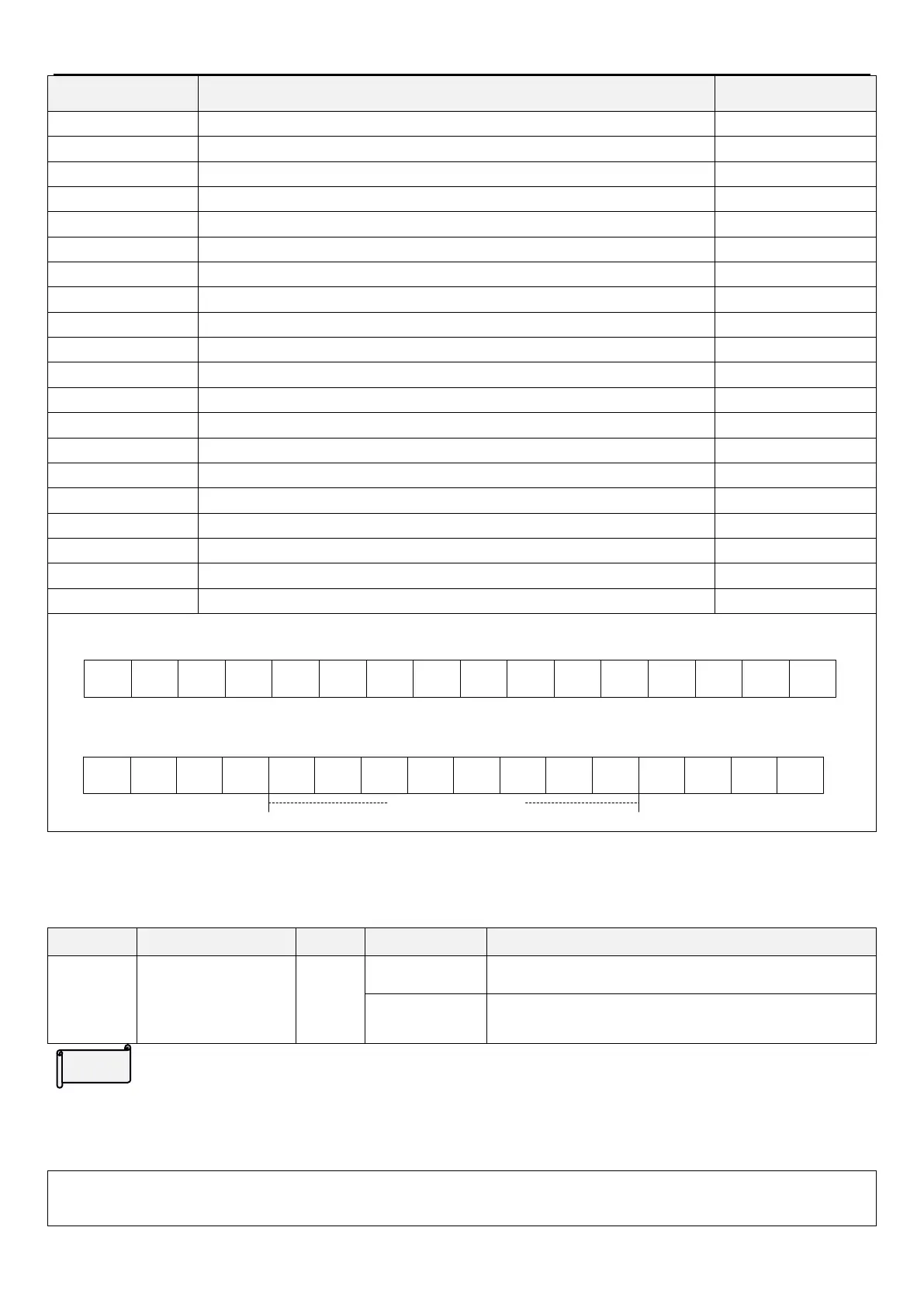

5.8.2 Communication EEPROM write selection

Use this function if parameter settings are frequently written by communication.

Communication

EEPROM write-in

selection

When writing parameters in communication mode, write in

RAM and EEPROM

When writing parameters through communication, only write

into RAM

Communication EEPROM write selection

When parameter write in is performed by RS-485, parameters can store in EEPROM + RAM or RAM only.

If change parameter value frequently, set "1" in 07-11(P.34). When 07-11(P.34) set to "0" EEPROM lifetime will be

shorter due to constantly write in.

Note: Set 07-11 (P.34) =1 (RAM only), when the power of inverter is turned off, parameters changed will not be

memorized. When power on again, all parameters will still be the setting previously saved in EEPROM.

Loading...

Loading...