Tension control parameter group 14

PARAMETER DESCRIPTION 260

When 14-04

(P.604)

is 2,tension is set via communication.When controlling using upstream model,tension can be

set by communication.There are two ways to set tension by communication,one is to alter the value of 14-05

(P.605)

(14-04

(P.604)

should be set to 0),the other is to set via modbus address H100C (14-04

(P.604)

should be set to

2).The setting range of modbus address H100C is 0~30000.

14-07

(P.607)

is the zero speed tension increase option, used to set the tension of the system during zero speed. It

is mainly used to overcome the static friction at startup or keeping in a certain tension in zero speed.When

controlling small tension or having startup difficulties, appropriately increase the value of this parameter.

14-08

(P.608)

is the zero speed threshold parameter.When inverter operation speed is lower than this parameter,it is

considered working under zero speed.

14-09

(P.609)

is the tension taper parameter.This parameter is only used for winding control.When winding,there are

times that would be necessary to reduce the tension when increasing the winding radius in order to ensure the

material quality.

The formula of tension taper:

F=F0* 1 K* 1 D0+D1 / D+D1

F: actual tension,F0 : set taper,D0:shaft diameter,D:actual winding diameter,D1:parameter 14-10(P.654)`s

tension taper compensation value,K: tension taper.

Parameter 14-10(P.654) is the tension taper compensation value, which is able to slow down the tension decrease.

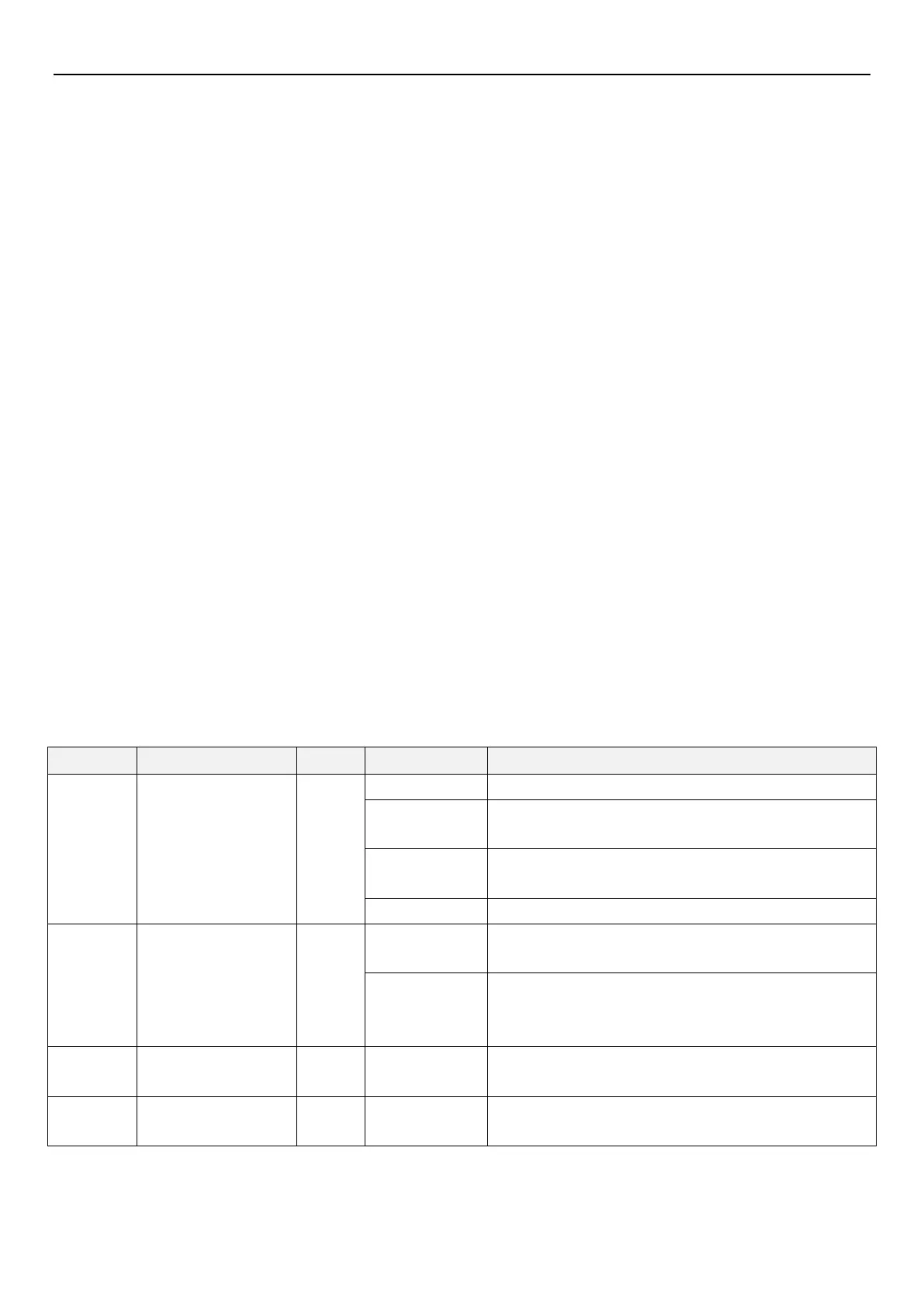

5.15.3 Curling radius calculation

The output torque is controlled by curling radius in open–loop torque mode. The output frequency corresponded to

line speed is gained by curling radius in close–loop speed mode.

Winding radius

calculation option

Calculate winding radius with linear speed

Calculate by thickness(encoder of motor side),pulse signal

connects to A1/B1 of PG card

Calculate by thickness (encoder of winding shaft),pulse

signal connects to M2 terminal

Analog value or pulse input

Calculate winding

memory control by

thickness calculation

Not saving winding radius when power outage

or calculation stops

Save winding radius when there’s a power outage or

calculation stops,and use saved winding radius as initial

winding radius when power recovers or calculation restarts

Loading...

Loading...