Speed and torque control parameter group11

PARAMETER DESCRIPTION 235

Note: 1. Increase 11-00(P.320) / 11-03(P.323) / 11-23(P.412) speed control gain can elevate response. But set too high can

generate vibration and noises.

2. Reduce 11-01(P.321) / 11-04(P.324) / 11-24(P.413) speed control integral coefficient can shorten the time required

to go back to the original speed. But if the value is too small, overshoot can happen.

3. When the setting value of 11-06(P.326) is increased, the response of the current regulator is improved, but if the

setting value is too large, the current control will oscillate and there will be a large electromagnetic noise.

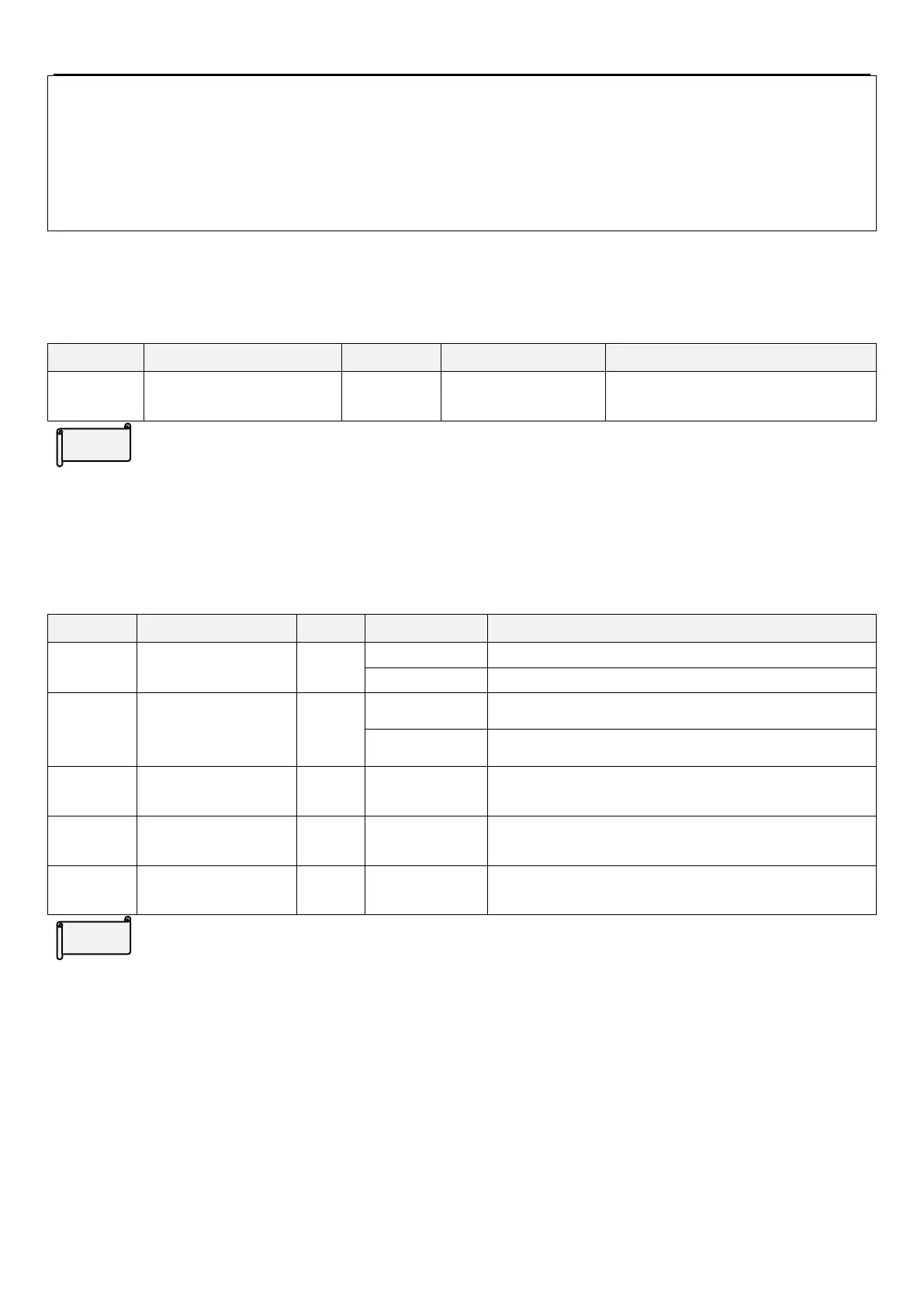

5.12.2 IM motor estimated speed filtering time

Set the estimated low-pass filter time for the speed of the IM motor in sensorless vector control.

IM motor estimated speed

filtering time

Only valid when 00-21(P.300)=3

IM motor estimated speed filtering time

When in sensorless vector control, if the motor control oscillates, 11-26 (P.415) can be properly adjusted, usually

no setting is required.

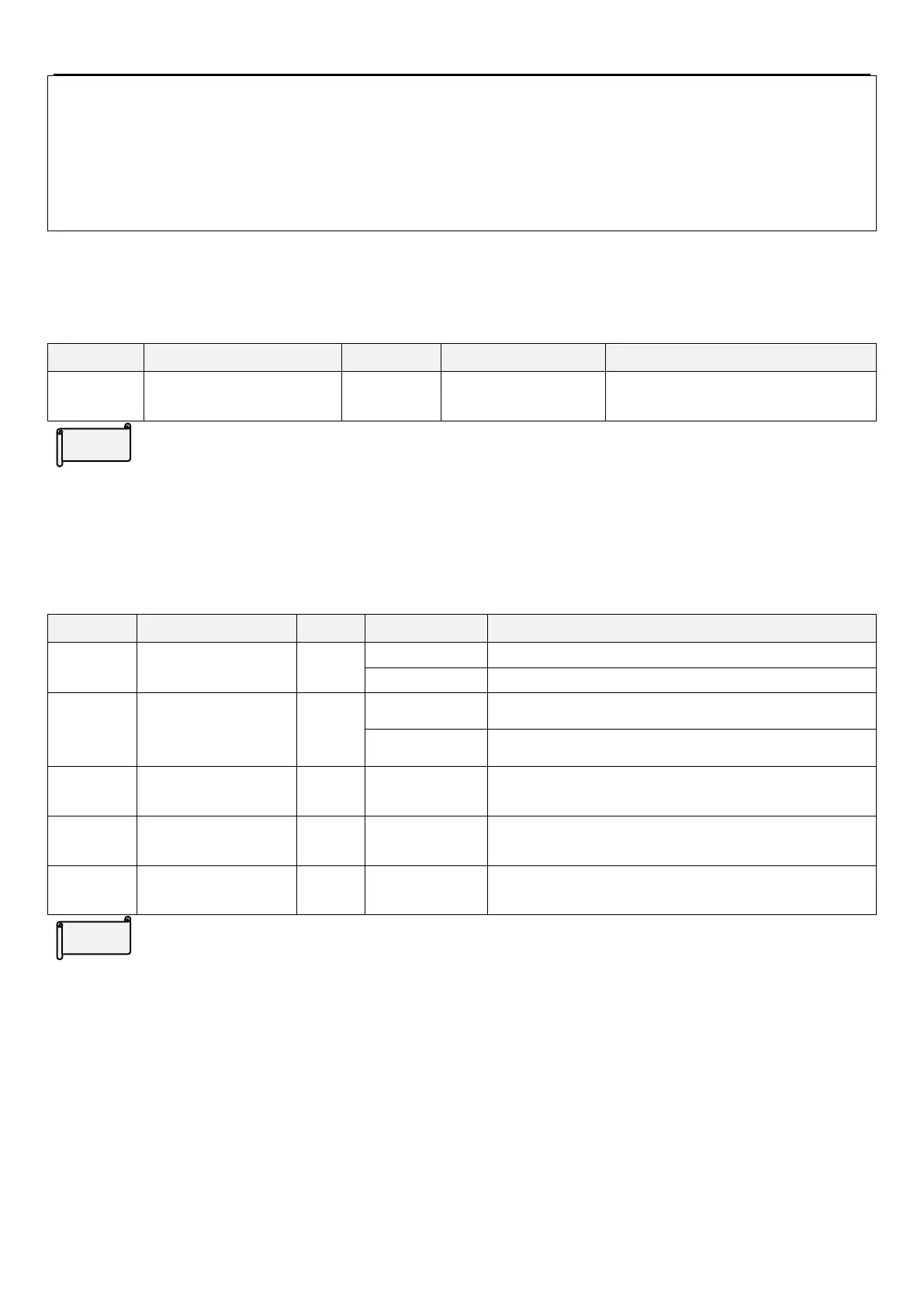

5.12.3 PM motor setting

The parameters setting below can improve the VC and SVC control characteristic of PM motor.

PM motor initial

position detection

method

id given at acceleration, valid only when 00-21=6

PM motor constant

speed id

id given at constant speed, valid only when 00-21=6

PM motor estimated

speed filtering time

PM motor estimated rotation speed filter time constant, valid

only when 00-21=6

PM motor control setting

11-08

(P.328)

is used to select how the rotor position is detected at PM motor start. In PM motor close-loop vector

control

mode, inverter performs a magnetic pole search the first time it starts the motor. After that, rotor position is

calculated from the PG encoder signal and saved until the inverter power is switched off.

When 11-08

(P.328)

=0, detect initial magnetic pole position of the rotor by using pull-in method, the motor cannot

start with heavy duty, or it may fail to start.

When 11-08

(P.328)

=1, detect the initial magnetic pole position of the rotor by using high frequency pulse vibration

method, electromagnetic noise may be generated from the motor at start.

11-09

(P.329)

is the current for pulling in the pole when PM motor starts. 05-05

(P.306)

(motor rated current) is set to

100%, setting the pull-in current during acceleration/deceleration, adjustments to this setting may help in the

following situations:

Increase this setting when a large amount of starting torque is required.Lower this setting if there is excessive

Loading...

Loading...