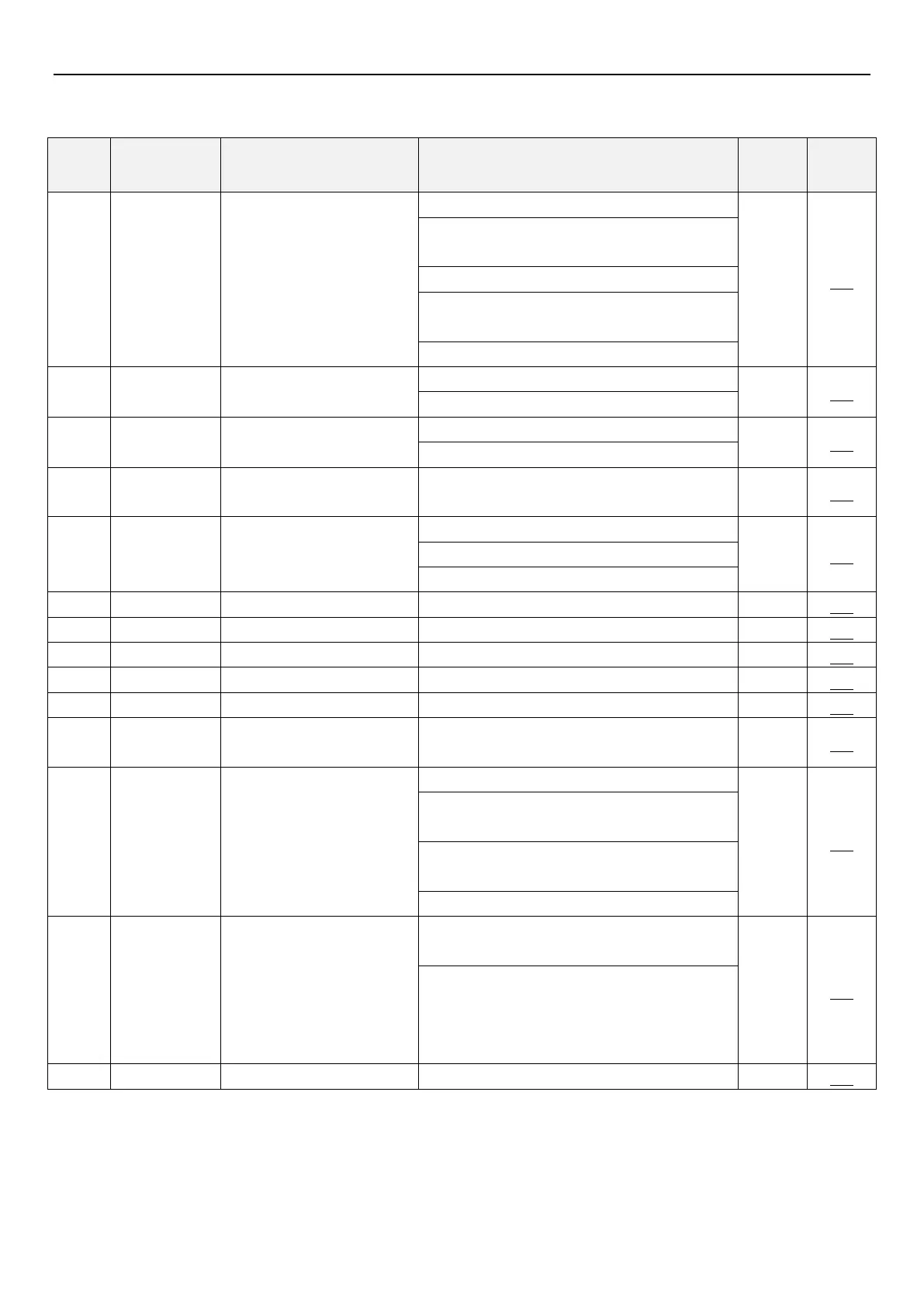

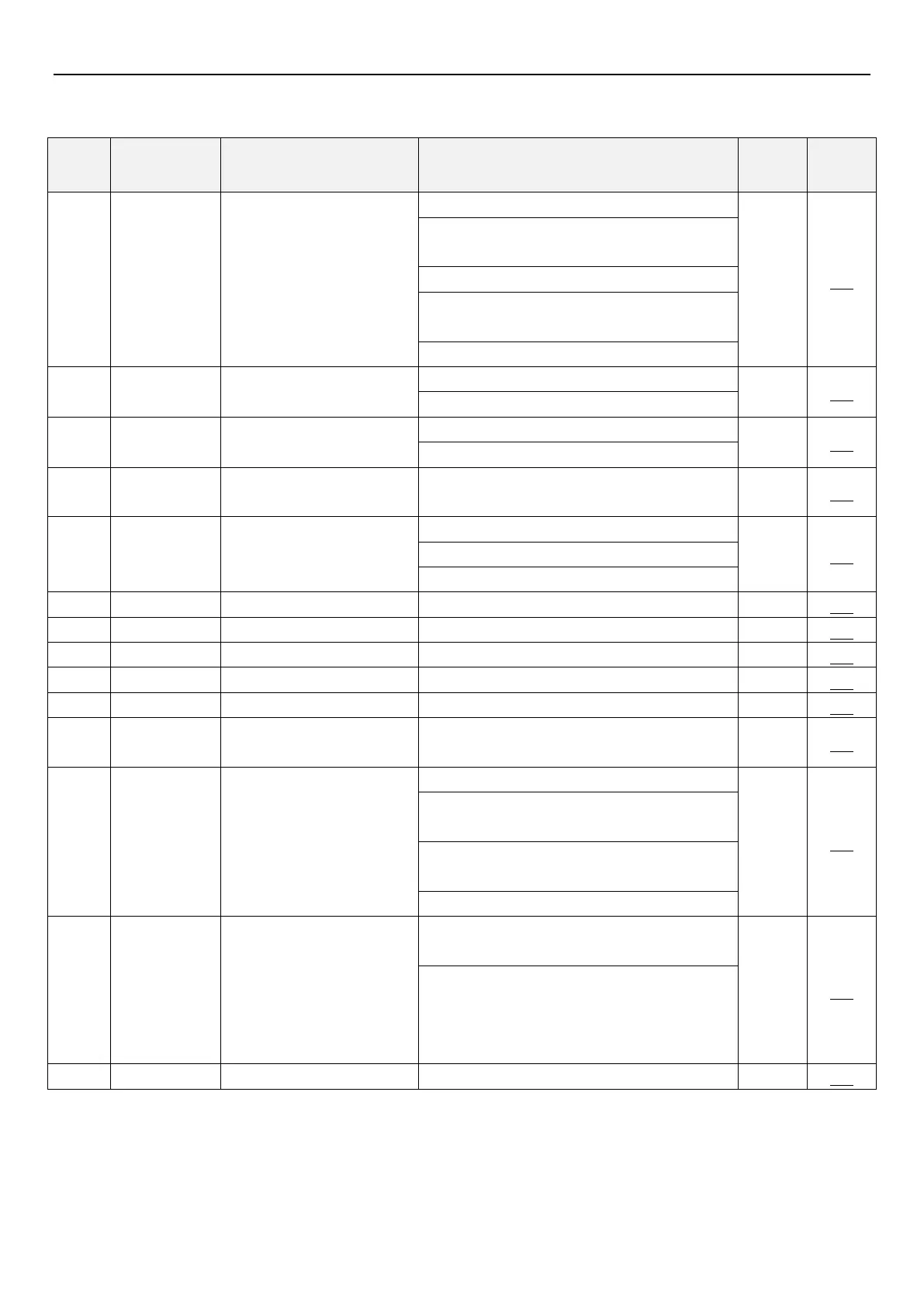

Tension control parameter group 14

PARAMETER DESCRIPTION 255

5.15 Tension control parameter group 14

Tension control parameter

1:Open loop torque control mode(under closed

loop vector control mode)

2:Closed loop speed control mode

3:Closed loop torque control mode(under closed

loop vector control mode)

4:Constant linear speed control mode

Tightening roll option

when releasing

0:Forbid tightening material during startup

1:Allow tightening material during startup

Mechanical transmission

ratio

0:Parameter 14-05(P.605)setting

1:Analog value or PULSE input setting

Zero-speed tension increase

Taper compension correction

value

Winding radius calculation

method options

0:Calculate by linear speed

1 : Calculate by thickness(encoder of motor

side),pulse signal connects to A1/B1 of PG card

2:Calculate by thickness (encoder of winding

shaft),pulse signal input to terminal M2

3:Analog value of pulse input

Calculate winding memory

control by thickness

calculation

0 :Do not save winding radius when power

outage or calculation stops

1:Save winding radius when there’s a power

outage or calculation stops,and use saved

winding radius as initial winding radius when

power recovers or calculation restarts

Loading...

Loading...