System parameter group00

PARAMETER DESCRIPTION 70

Carrier frequency

The higher the carrier frequency, the lower the motor acoustic noise, but will result in greater leakage current and

larger noise generated by the inverter.

The higher the carrier frequency, the more energy inverter will consume, and temperature will also be higher.

If mechanical resonance occurred in a system, 00-11

(P.72)

can also be adjusted to lower the vibration.

Note: The setting value of carrier frequency is best to be 8 times larger than the target frequency.

Carrier operation selection

Soft-PWM control is a control method that changes the motor noise from a metallic sound into an inoffensive,

complex tone.

Motor noise modulation control is when the inverter changes its carrier frequency from time to time during

operation, metal noises generated by the motor will not be in a single frequency, so sharp single frequency noises

will be reduced.

This function is only usable under V/F control mode; i.e., it is usable when 00-21(P.300)=0.

5.1.7 Stop operation selection

Select the inverter stop method

button and inverter stop running in PU and

H2(combine mode 2) mode

button and inverter stop running in all

mode.

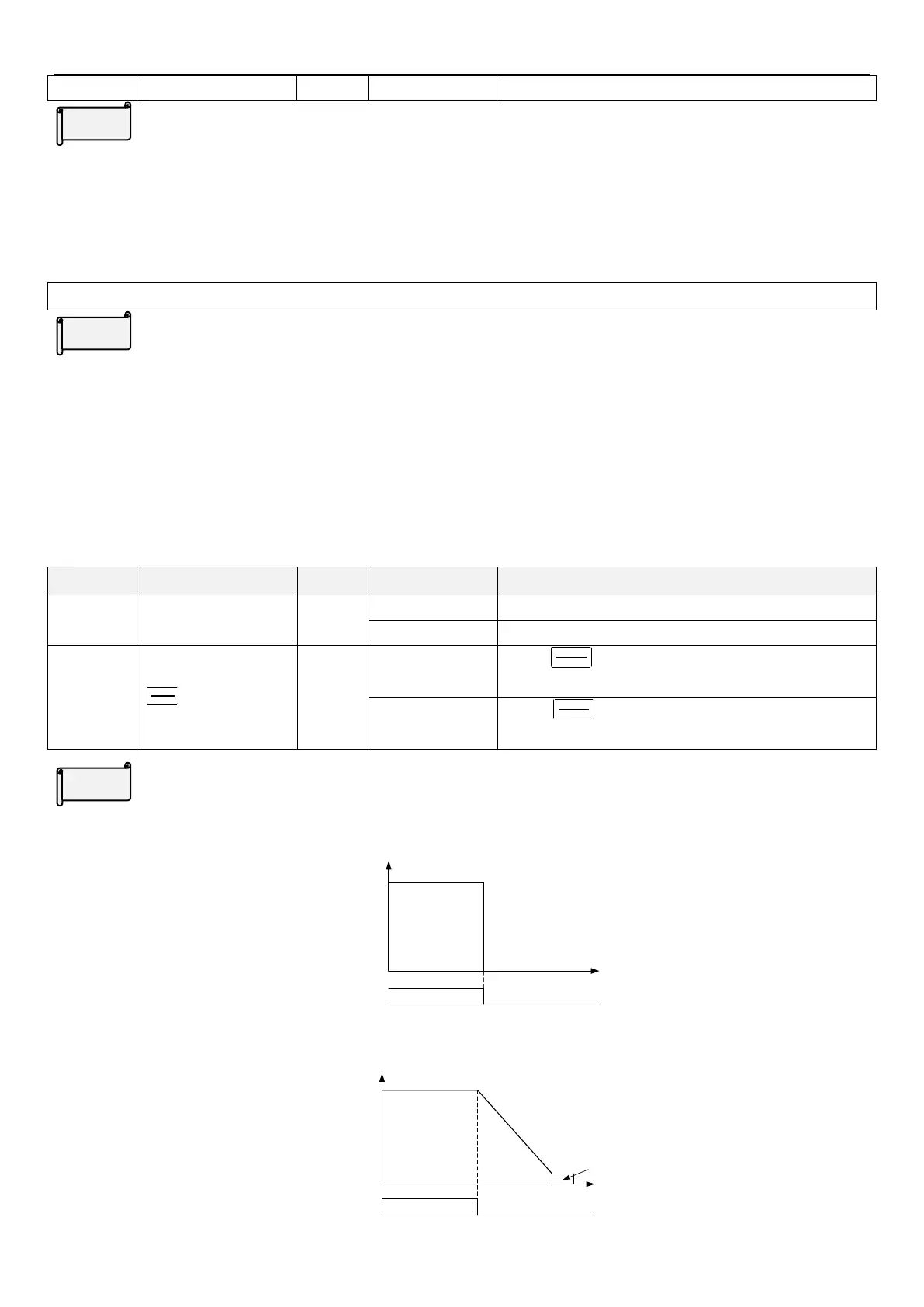

Idling brake / DC brake

Idling brake (00-13(P.71)=“0”)

After receiving stop signal, inverter stops output immediately, and the motor idle freely.

ON OFF

Operation

signal

time

Output frequency

(HZ)

The motor idling breaking

DC braking(00-13(P.71)=“1”)

After receiving stop signal, inverter decelerates according to the acceleration/deceleration curve until it stops

completely.

time

Output frequency (Hz)

ON OFF

Operation

signal

Deceleration time

(the time is set by P.8)

linear

braking

Loading...

Loading...