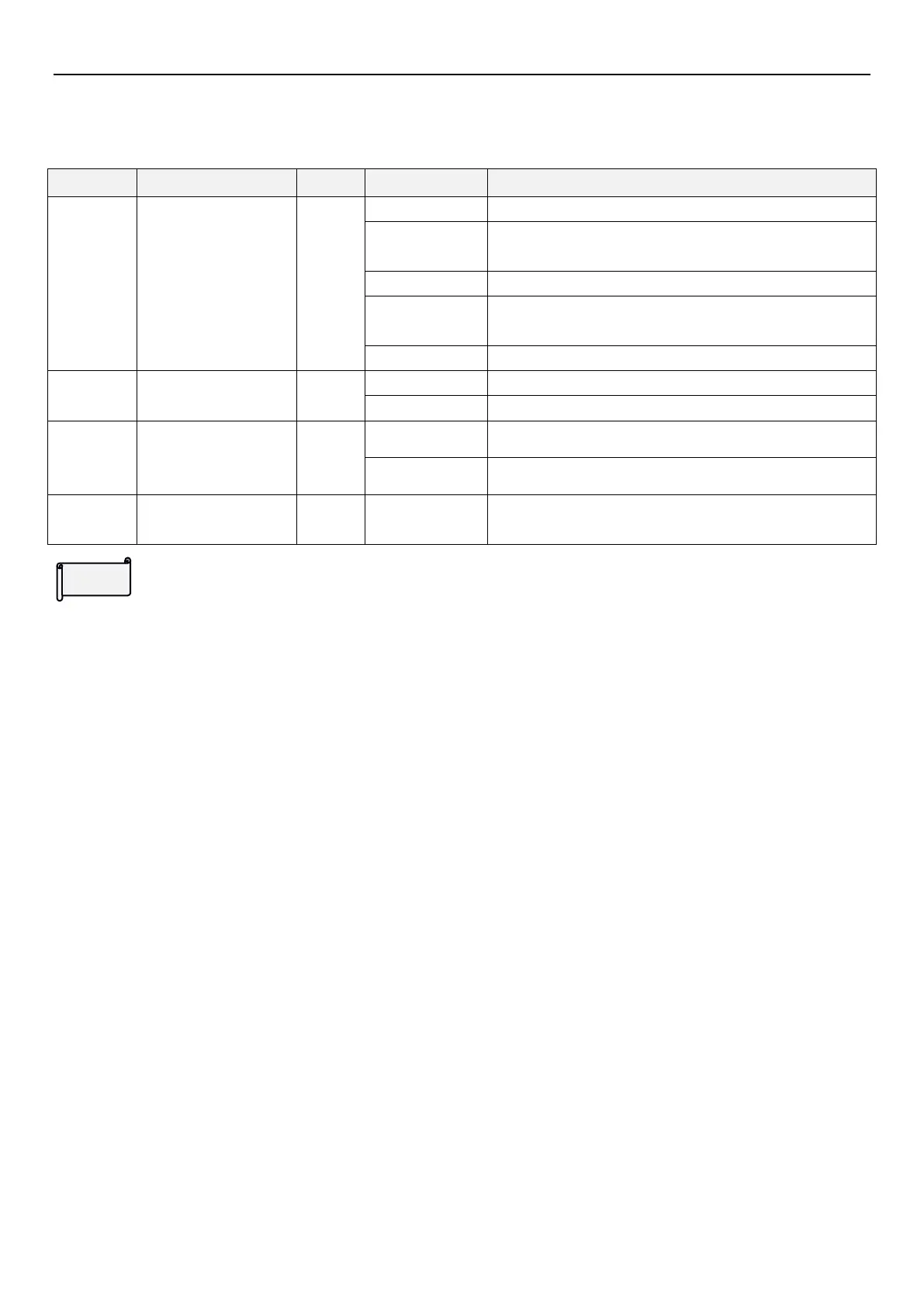

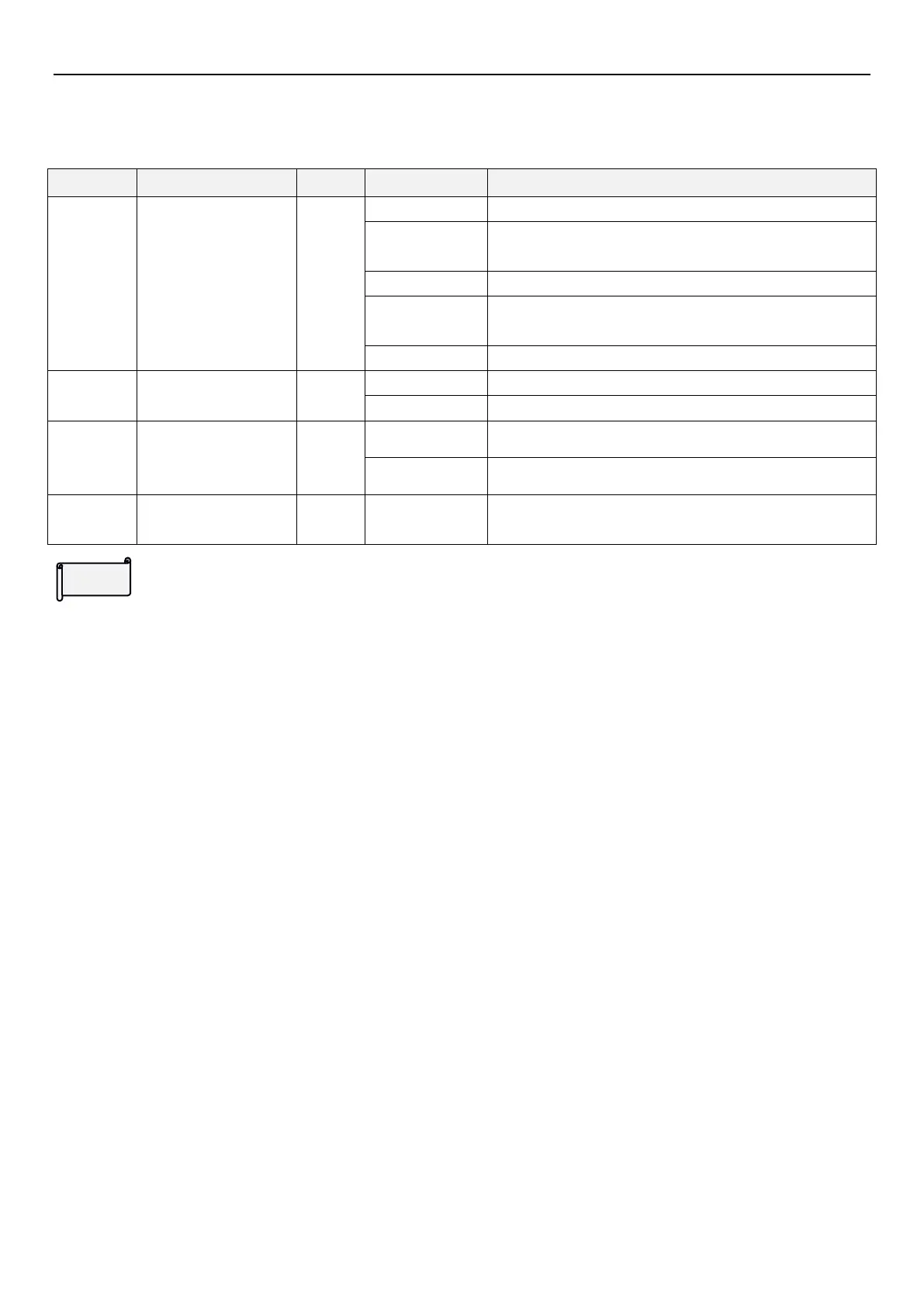

Tension control parameter group 14

PARAMETER DESCRIPTION 258

5.15.1 Tension control mode selection

Tension control mode selection

Tention control mode

selection

Open-loop torque control mode(Under closed-loop vector

control)

Closed-loop speed control mode

Closed-loop torque control mode(Under closed-loop vector

control mode)

Linear speed control mode

Tightening roll option

when releasing

Forbid tightening material during start-up

Allow tightening material during start-up

Mechanical transfer

ratio

Mechanical transfer ratio

Tension control mode

When 14-00

(P.600)

is 0,tension control invalid,inverter is identical to general inverter.

When 14-00

(P.600)

is 1,opened-loop torque control mode is activated.The inverter keeps the tension consistent

through controlling the output torque of the motor.Tension feedback is not required,but speed detection encoder

must be installed when the inverter is working under closed-loop vector control mode.

When 14-00

(P.600)

is 2,closed-loop speed mode is activated.The controlling result is to make the tension(position)

feedback signal stable at the value given by PID.

Closed-loop means that tension (position) detection feedback is required to form a closed-loop

adjustment.Speed control mode means that the inverter adjusts frequency according to feedback signal to achieve

control.This program is operable in any motor control mode,i.e. 00-21 is able to be set to 0~4.

When 14-00

(P.600)

is 3,closed-loop torque control mode is activated.Tension feedback closed-loop adjustment is

added on the basis of opened-loop tension control.The tension signal fed back by the tension detection device and

the tension setting value constitute the PID closed-loop adjustment which is used to adjust the inverter output

torque reference.The control method of it works under closed-loop vector control.The speed encoder must be

installed.

When 14-00

(P.600)

is 4,constant linear speed mode is activated.This is a special application in order to exclude the

need of PID adjustment in operating constant linear control,which is more stable than the normal closed-loop

control and applicable to some situations that require stable operation and doesn’t require rapidly adjusting linear

speed. This program is operable in any motor control mode,i.e. 00-21 is able to be set to 0~4.

Loading...

Loading...