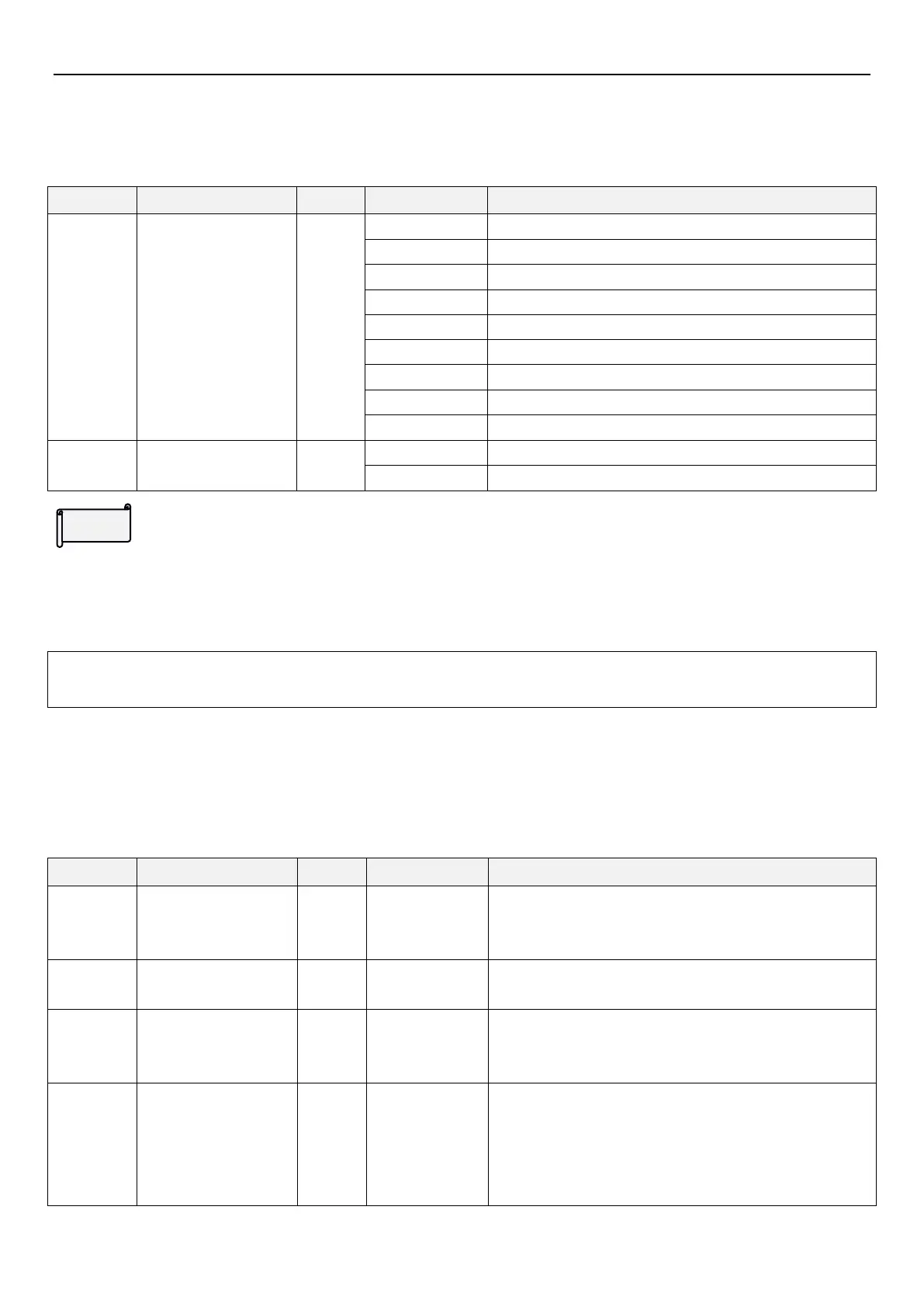

PG feedback parameter group 09

PARAMETER DESCRIPTION 189

5.9.1 PID function selection

Inverter can control flow, volume or pressure by PID control. By using analog signal or parameter setting as target

source, and with analog signal as feedback source, it forms a closed loop control system.

Parameter 08-03(P.225) as target value.

Terminal 2-5 input as target source

Terminal 4-5 input as target source

Terminal HDI input as target source

Terminal 2-5 input as feedback source

Terminal 4-5 input as feedback source

PID feedback control

method

Negative feedback control.

Positive feedback control.

PID function selection

During PID control, frequency displayed on screen is inverter output frequency

For terminal 2-5 and terminal 4-5 input signal filtering please refer to parameters 02-10

(P.60)

02-22

(P.528)

.

Note: When setting target source and feedback source, please pay attention to 08-00(P.170) and

02-00(P.500)~02-01(P.501) setting, terminal priority : 2-5 > 4-5 .

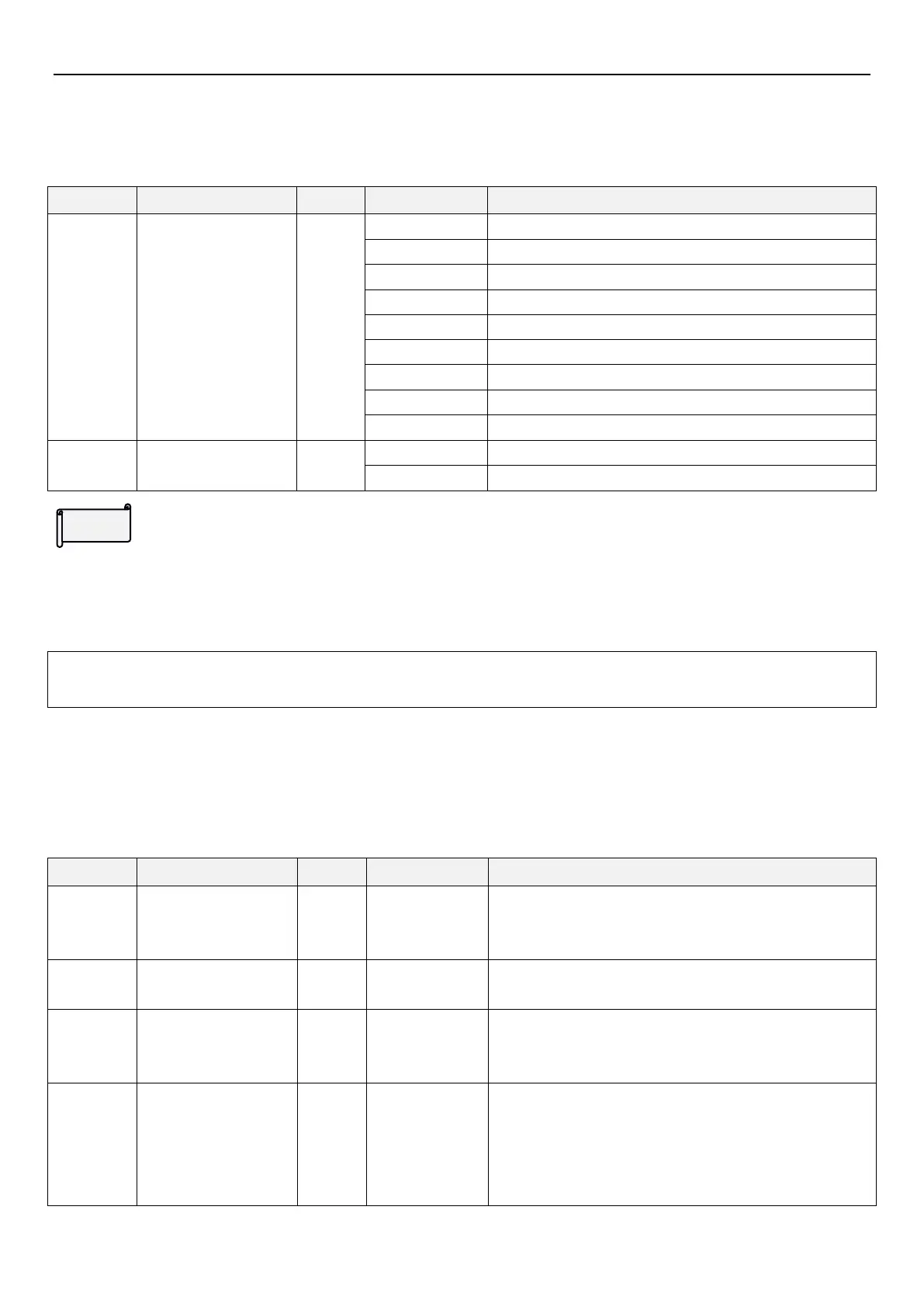

5.9.2 PID parameter group 1

By setting PID parameters users can realize automatic adjustment of process control.

Feedback signal sampling period.Adjuster computes once

every sampling period. The longer the sampling period, the

slower the response.

When ten-digit of 08-00 (P.170) is set to 0 and single-digit is

not set to 0, the target value is set by 08-03(P.225)

This gain determines the proportion controller’s response on

feedback deviation. The greater the gain, the faster the

response. Gain set too high will cause vibration.

This parameter determines integral controller’s integral time.

When integral gain is too high, integral effect will be too

weak to eliminate steady state deviation. When integral gain

is rather small, the system vibration time will increase, and

too small integral gain will cause system unstable.

Loading...

Loading...