Arrangement of control terminal

INVERTER INTRODUCTION 43

(2) Crimp the blade terminal.

Insert wires to a blade terminal, and check that the wires come out for about 0 to 0.5 mm from a sleeve.

Check the condition of the blade terminal after crimping. Do not use a blade terminal of which the crimping is

inappropriate, or the face is damaged.

Please do use blade terminals with insulation sleeve. Blade terminals commercially available:

Crimping tool

product

number

Phoenix

Contact

Co., Ltd.

Note:1. Please Use a small flathead screwdriver (tip thickness: 0.6mm, width: 3.0mm). If a flathead screwdriver with a

narrow tip is used, terminal block maybe damaged.

2. Tightening torque is 2.12~3.18 kgf.cm, too large tightening torque can cause screw slippage, too little

tightening torque can cause a short circuit or malfunction.

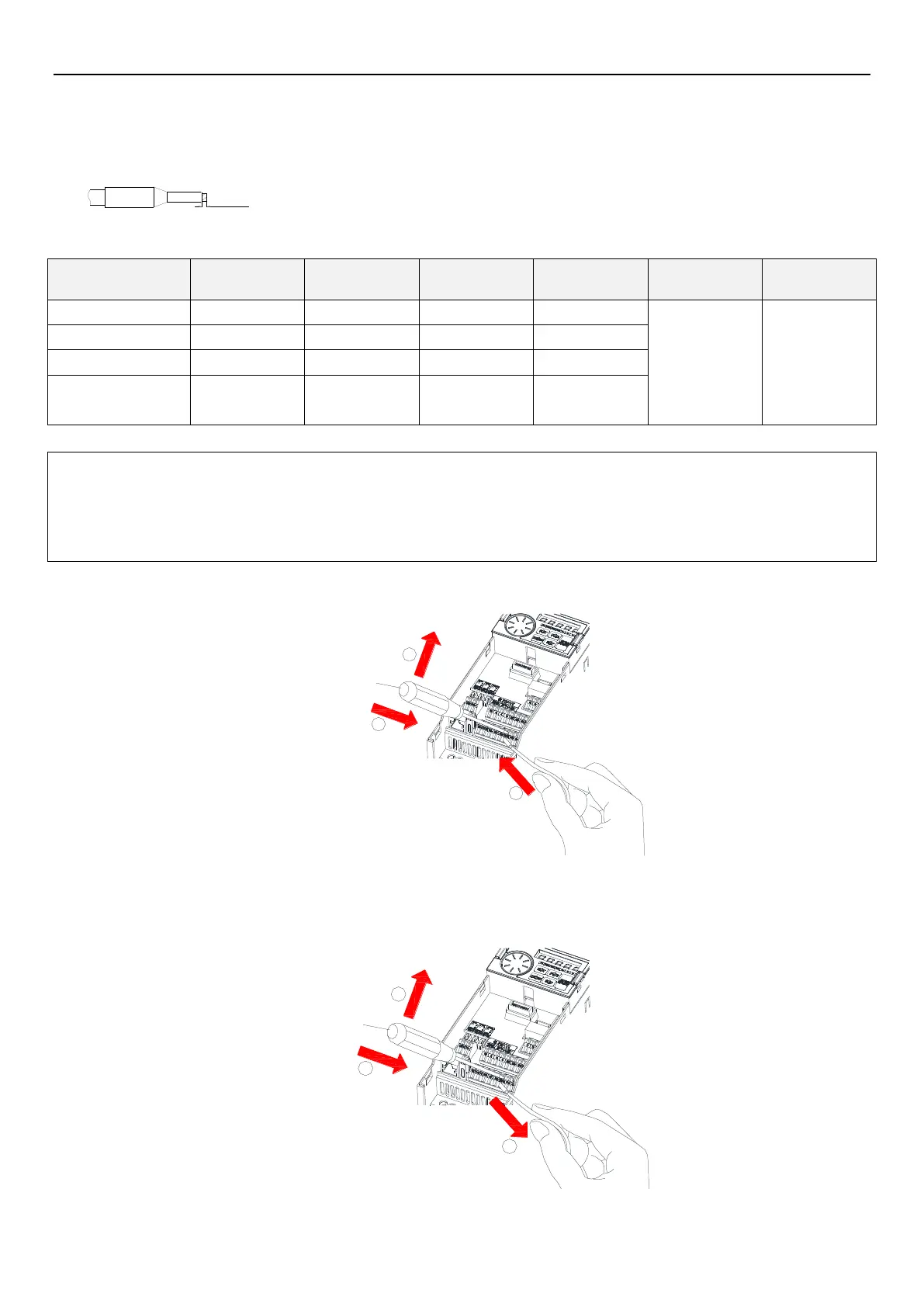

Wiring installation

First insert slotted screwdriver with terminal blocks, pressing terminal blocks down, and then insert the electric wires.

Wiring demounting

First insert slotted screwdriver with terminal blocks, and pressing terminal blocks down, and then pull out the wire.

Loading...

Loading...