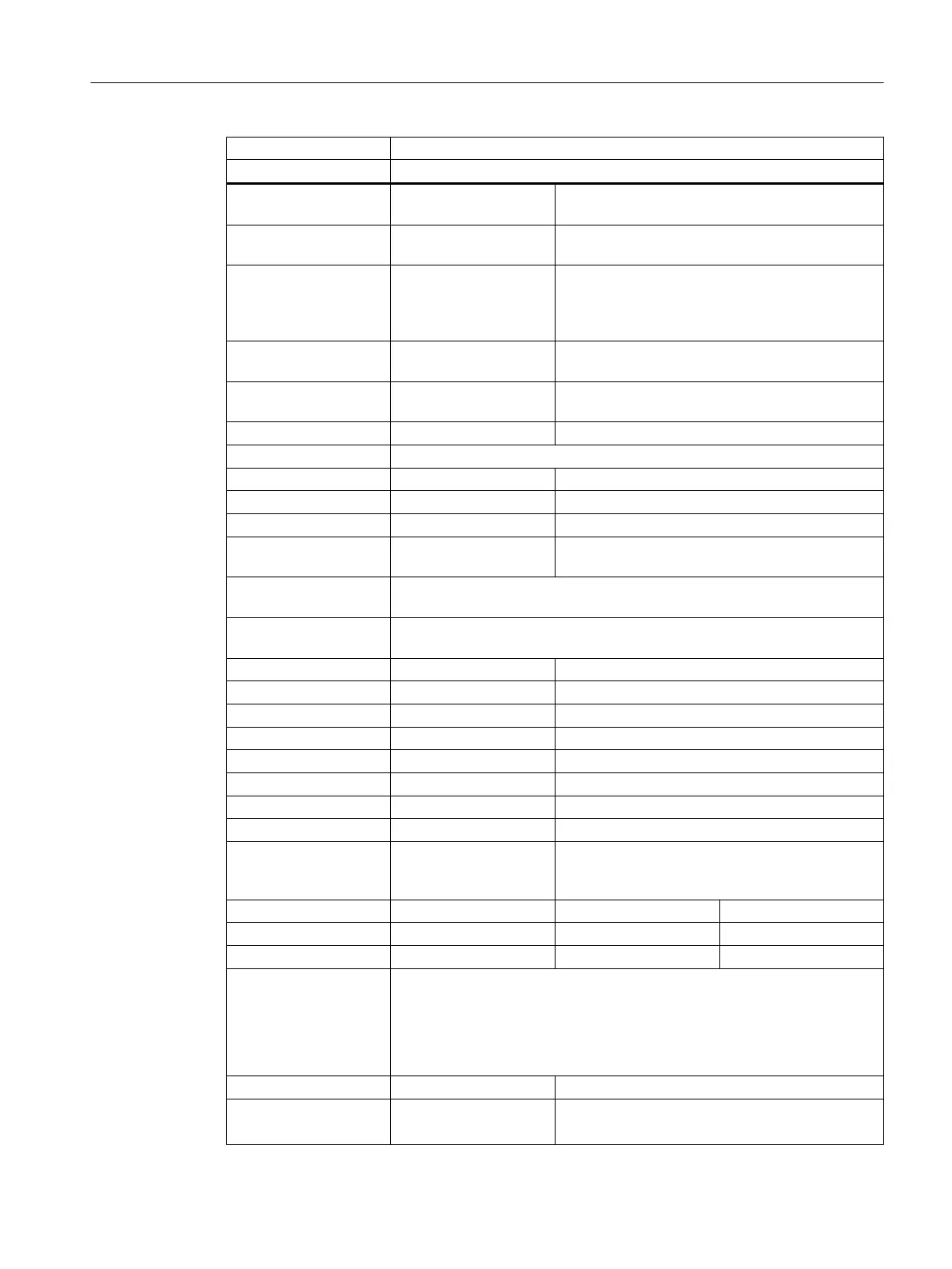

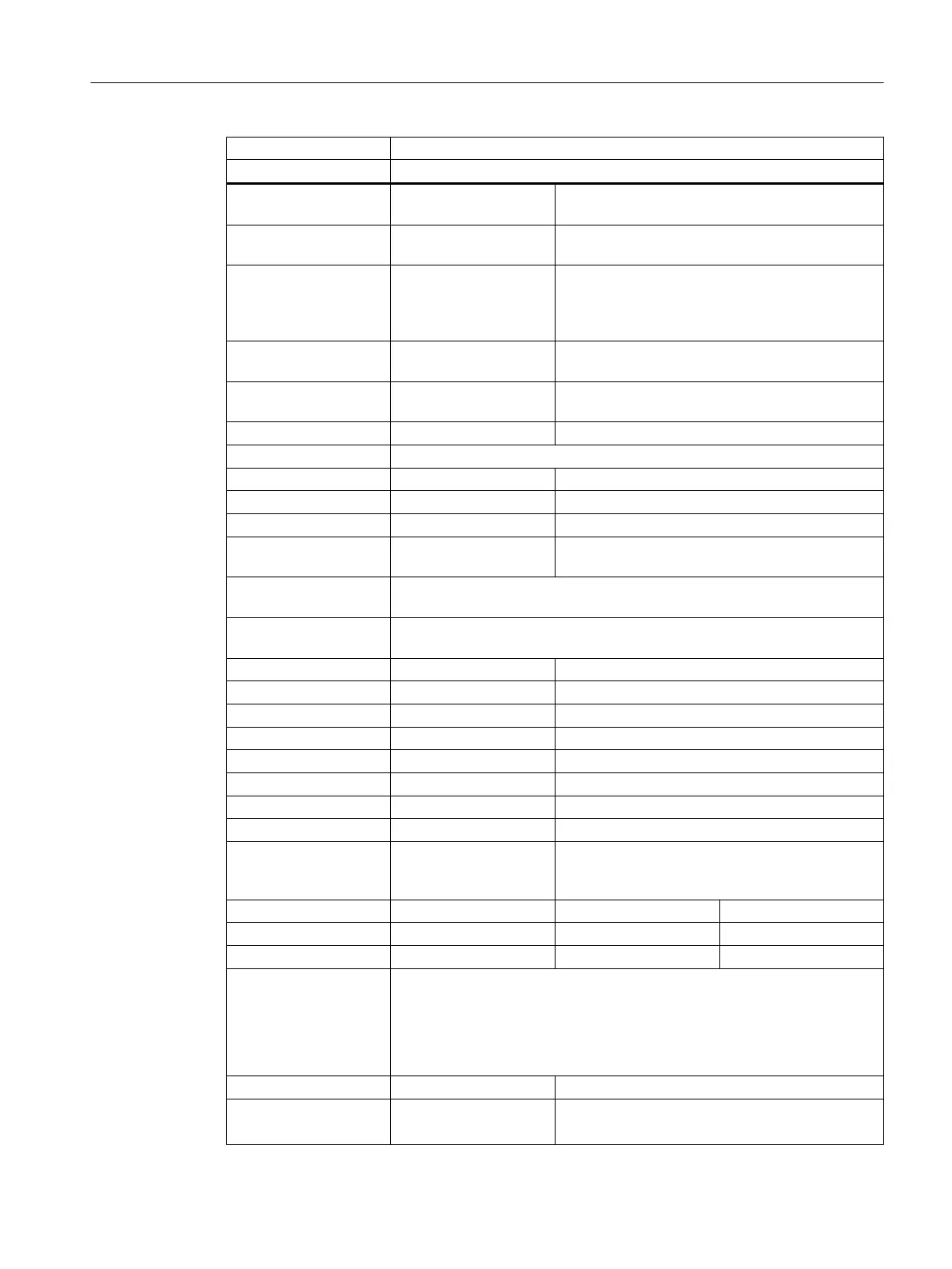

$TC_CARR37[n] Display variants of the input screens for CYCLE800

Decimal place Meaning

3 = Direction reference, rotary axis 1, direction selec‐

tion Minus in the basic setting of the kinematics.

4 = Direction reference, rotary axis 2, direction selec‐

tion Minus in the basic setting of the kinematics.

5 = No direction reference display for kinematics

which only have one solution. Direction selection

(_DIR) Plus is generated in the cycle call CY‐

CLE800.

8 = Direction reference, rotary axis 1, direction selec‐

tion Plus in the basic setting of the kinematics.

9 = Direction reference, rotary axis 2, direction selec‐

tion Plus in the basic setting of the kinematics.

The values 1, 2, 6 and 7 are not permitted.

TEN THOUSANDS Selection field correction of the tool tip

0 = No display of the correction of the tool tip input field.

1 = Correction of tool tip by means of TRAORI.

2 = No correction of the tool tip.

3 = Correction of the tool tip: This function assumes

option "5-axis transformation (TRAORI)".

HUNDRED THOU‐

SAND

reserved

ONE MILLION / TEN

MILLION

Selection field, retraction

00 = No retraction

01 = Retraction Z

02 = Retraction Z, XY

03 = Retraction Z or Z, XY

04 = Maximum retraction in tool direction

...

08 = Incremental retraction in tool direction

...

15 = Retraction Z or Z, XY or

in maximum tool direction or in incremental tool

direction

$TC_CARR38[n] Retraction position X

$TC_CARR39[n] Retraction position Y

$TC_CARR40[n] Retraction position Z

HUNDRED MILLION Swivel data set enabled

Setting swivel data set change

Automatic

or manual tool

change is only necessary under ShopMill or Shop‐

Turn (→ see also: CUST_800.spf, markers _M2 to _M13).

A swivel data set must be "enabled" in every case (value ≥ 4).

0 = Swivel data set not enabled

4 = Swivel data set enabled

Automatic swivel data set and tool change

Configuring cycles

7.7 Swiveling

SINUMERIK Operate

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 147

Loading...

Loading...