Example

If the general cycle machine data SD54647 $SNS_MEA_TPW_AX_DIR_AUTO_CAL has the

value 123, the tool probe is calibrated as follows in the G17 plane:

● X in both directions

● Y only in plus direction

● Z only in minus direction

Monitoring when measuring with a rotating spindle

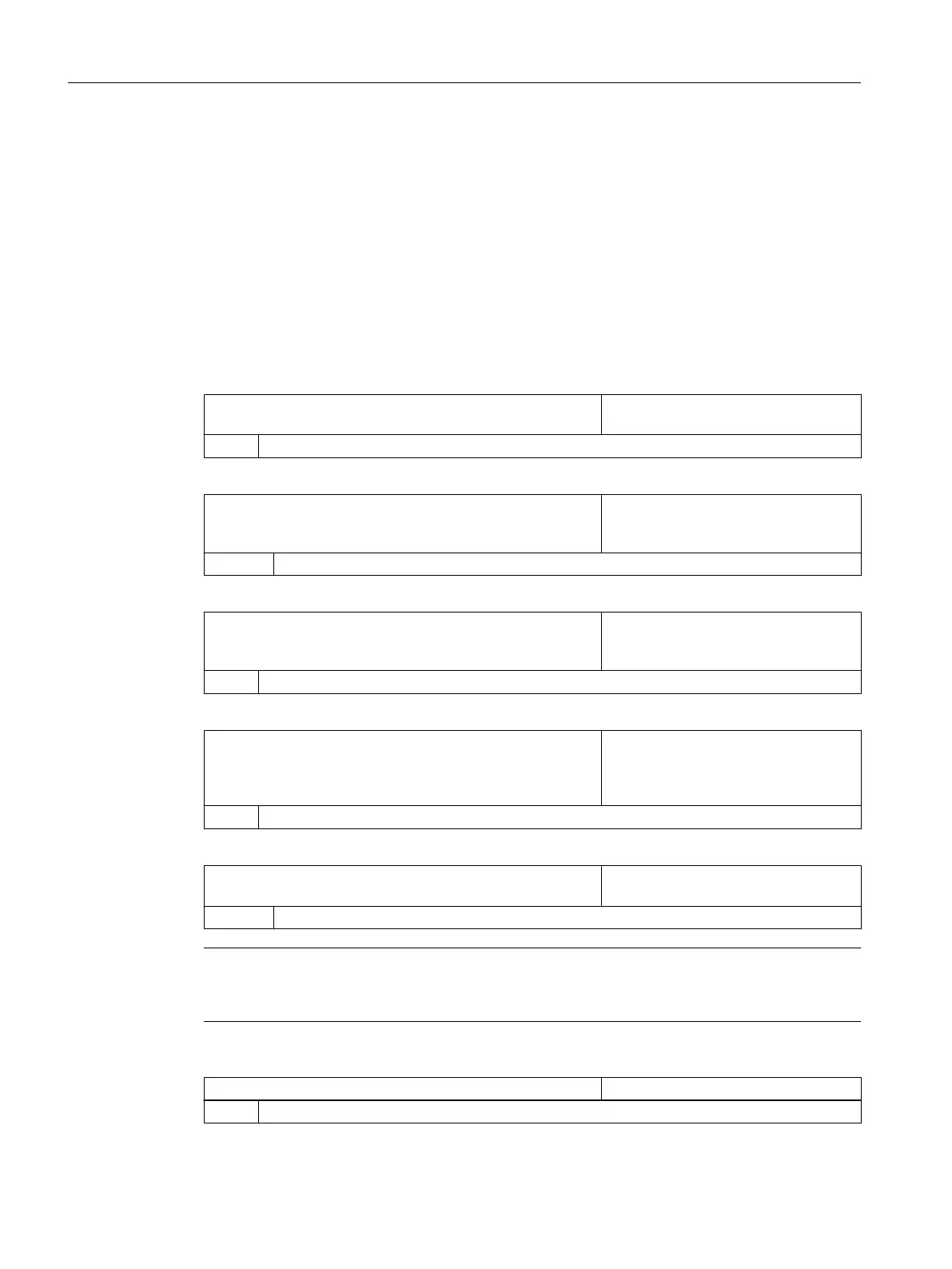

SD54670 $SNS_MEA_CM_MAX_PERI_SPEED[0] Maximum permissible peripheral

speed of the tool to be measured.

= 100

Default value

SD54671 $SNS_MEA_CM_MAX_REVOLUTIONS[0] Maximum permissible tool speed of the

tool to be measured. The speed is au‐

tomatically reduced when exceeded.

= 1000 Default value

SD54672 $SNS_MEA_CM_MAX_FEEDRATE[0] Maximum permissible feedrate to

probe the tool to be measured at the

probe.

= 20 Default value

SD54673 $SNS_MEA_CM_MIN_FEEDRATE[0] Minimum feedrate for the first probing

of the tool to be measured at the probe.

This avoids excessively small fee‐

drates for large tool radii.

= 1 Default value

SD54674 $SNS_MEA_CM_SPIND_ROT_DIR[0] Spindle direction of rotation to measure

tools.

4 = M4 Default value

Note

If the spindle is already rotating when the measuring cycle is called, this direction of rotation

remains independent of the setting of this data.

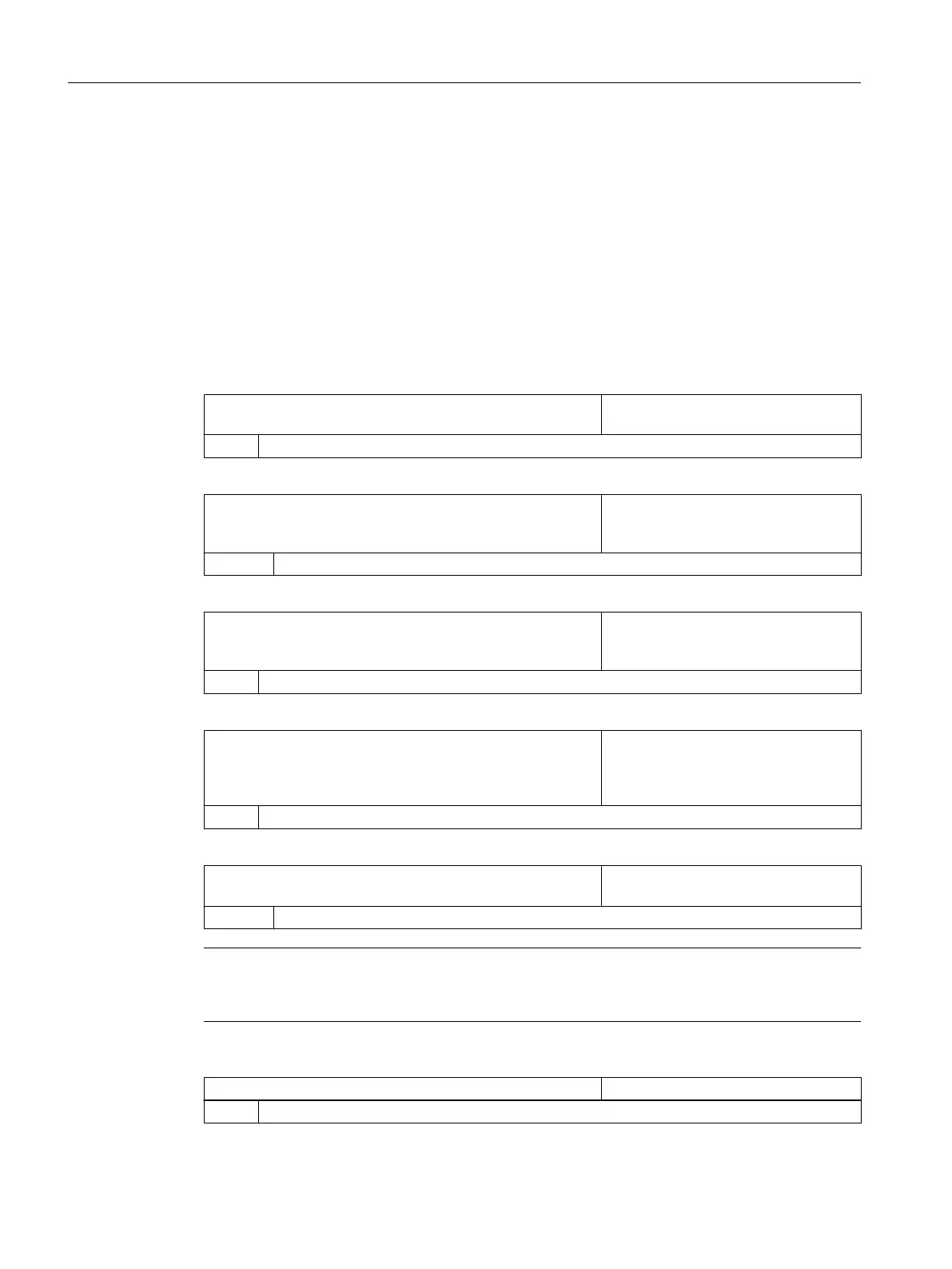

SD54675 $SNS_MEA_CM_FEEDFACTOR_1[0] Feedrate factor 1

= 10 Default value

Configuring cycles

7.9 Measuring cycles and measurement functions

SINUMERIK Operate

196 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...