1

WEILER E2850 REMIXING TRANSFER VEHICLE

3-34

Operating Instructions

3

Paving

12. Lower dump hopper baffle (12) to prevent material

from overloading elevator drive. For best results

and best use of machine power, position baffle to

keep storage hopper level in the green area, as

shown on decal.

13. Use an additional operator on the ground near

dump hopper to assist in dumping trucks. Hopper

controls are provided on ground stations at each

side of hopper. Optional truck signal lights may be

used to signal truck driver. (Refer to

"Truck Signal

Lights (Optional)", page 3-44.)

14. Back a haul truck up to the push rollers on the

dump hopper.

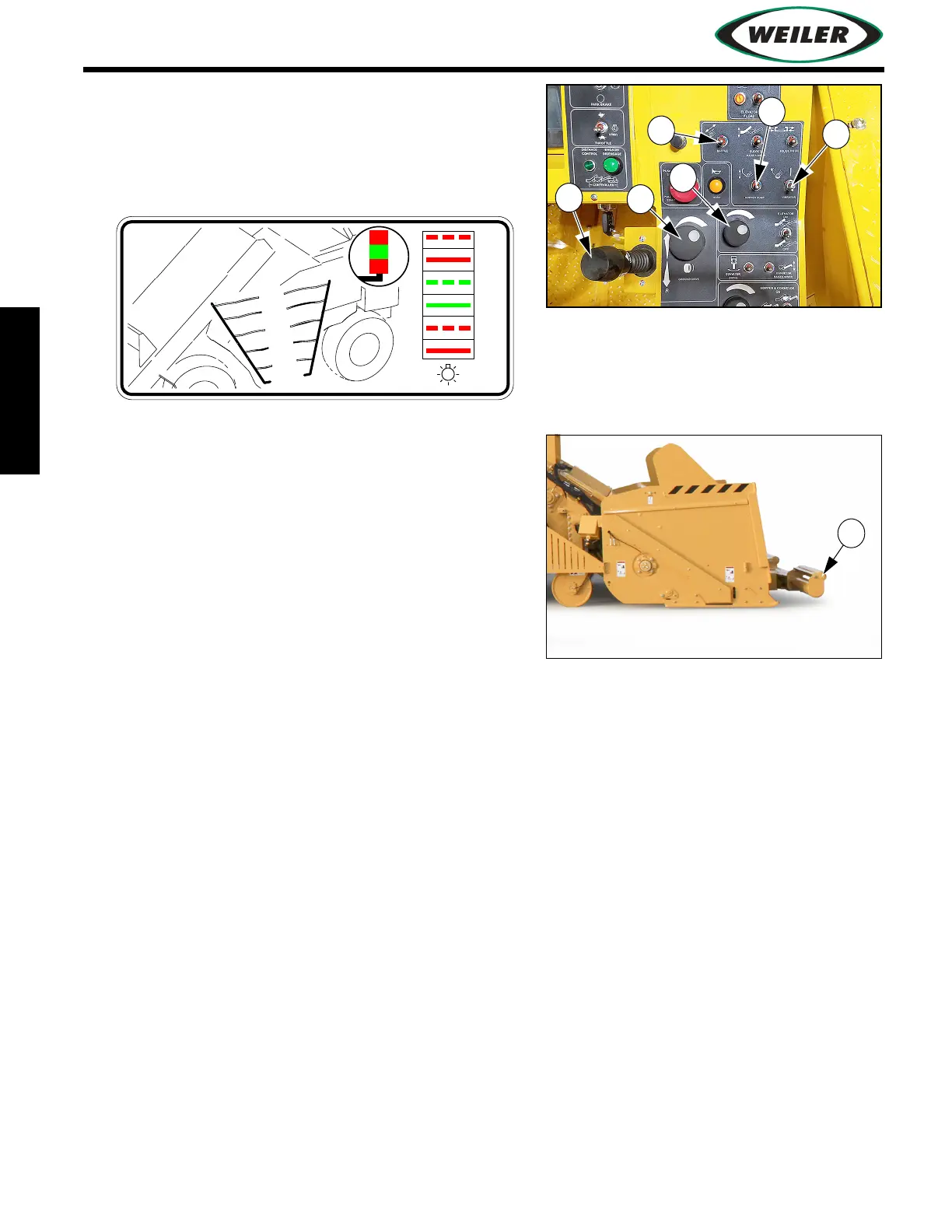

NOTICE: Adjust push roller position (13) to prevent

damage to dump hopper and flashing.

15. Slowly raise dump truck box until material begins to slide out. Adjust height of truck dump box

to control flow of asphalt into the dump hopper.

NOTICE: While unloading the first few trucks, meter material very slowly using the hopper baffle

and slow elevator chain speed. This allows steel machine parts to be lubricated and warmed up to

move material more easily through the machine. Material unloaded too quickly may stall elevator

and conveyor. If a stall occurs, refer to

"Cleaning or Removing Material", page 3-47.

16. Slowly open dump hopper baffle to allow material to contact remixing augers and elevator chain.

17. Fill storage hopper and paver hopper or optional hopper insert to near capacity.

18. When storage hopper and paver hopper or optional paver hopper insert are full, release park

brake and begin traveling at the speed of the paver.

Adjust speed with Propel Lever (14) and Propel Speed Dial (15). Set Propel Speed Dial to the

potential paving speed, then use Propel Lever to vary the speed. If equipped, refer to

"Distance

From Paver Control System (Optional)"

, page 3-38 for operating instructions.

19. Adjust material flow to discharge conveyor and paver hopper with Elevator Speed Dial (16).

Loading...

Loading...