01/02

3-12

8825/8830 Printer

PQ 7, PQ 8

Print Quality

PQ 7 Blurred Image PQ 8 Deletions (bands)

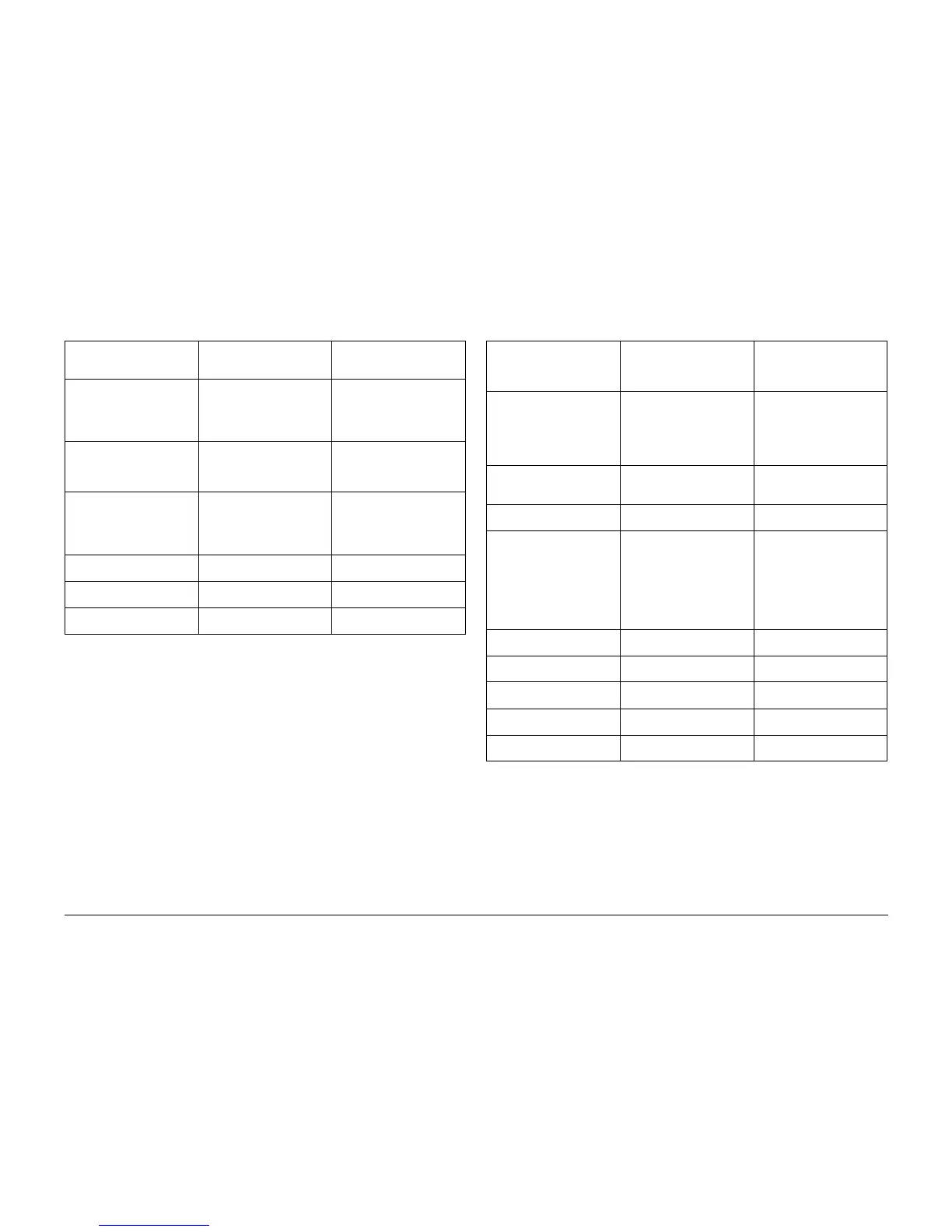

Table 1 Blurred Image Symptom / Check

Symptom/ check

The image is not clear or

sharp.

Probable Cause Corrective Action

1. Defective/contaminated

Image Module.

1A. Ensure the spacing rollers

and drum ends are not con-

taminated/defective.

1B. Clean the LED Array with

a lint-free cloth.

2. Contamination on Transfer/

Detack Corotron

2A. Clean or replace as

required.

2B. Perform GP 1, HVPS

Checkout Procedure.

3. Defective drive gear 3. Check the following drive

gears for damage:

a. drum drive gear

b. developer drive gear

c. cleaner drive gear

4. Defective registration roller 4. Replace as required ( PL

8.2).

5. Media transport 5. Check the Media Transport

gap ( ADJ 8.4).

6. Defective buckle control 6. Replace the buckle switch

( PL 8.4).

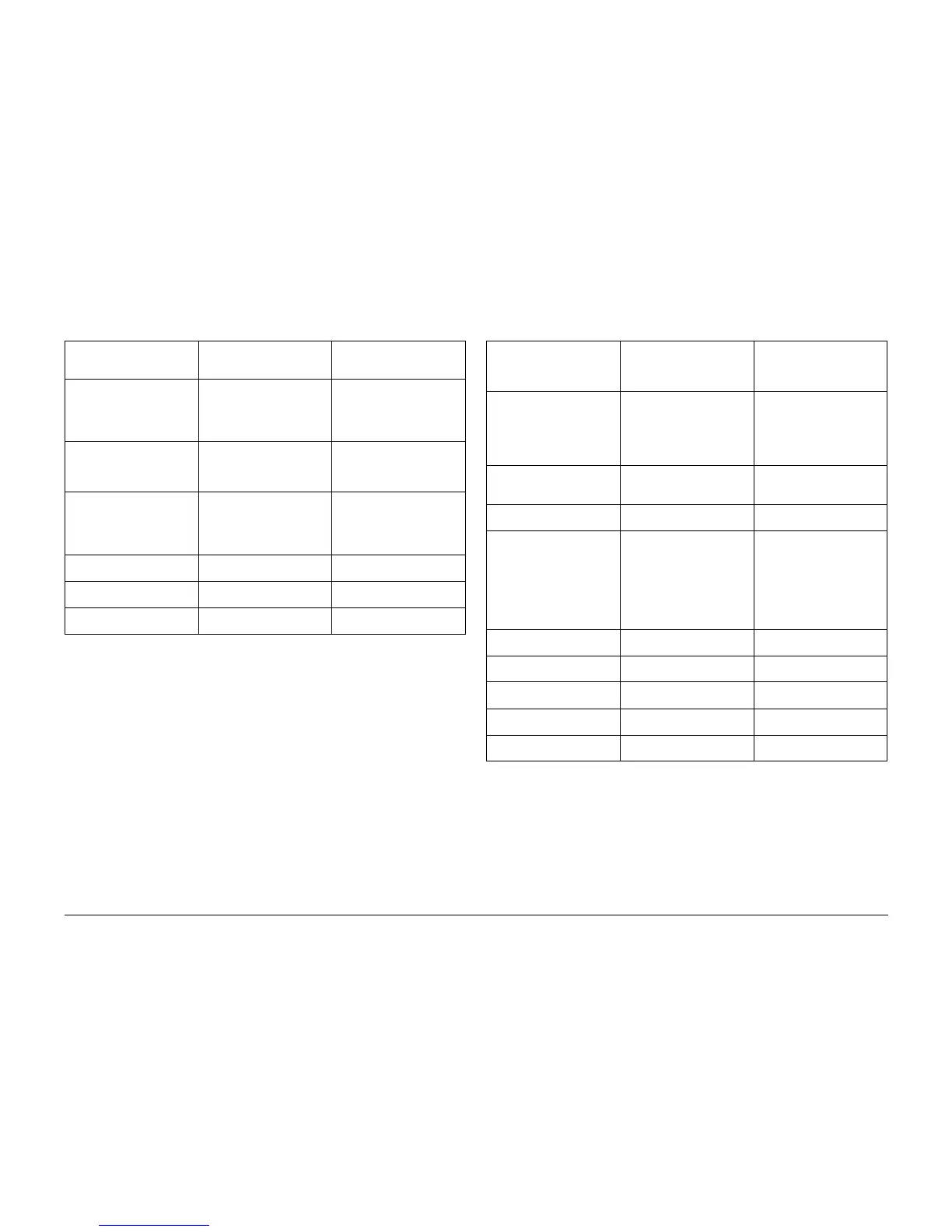

Table 1 Deletions (bands) Symptom / Check

Symptom/ check

Deletion bands or very low

image density in the print feed

direction.

Probable Cause Corrective Action

1. Damp media 1A. Refer to BSD 7.1 and

BSD 7.3 to check for correct

operation of the Paper heat-

ers.

1B. Ensure that the Customer

is storing the media correctly.

2. Corotrons 2A. Clean / replace or repair

the T/DT corotrons ( REP

9.9).

3. Defective HVPS 3. Perform GP 1, HVPS

Checkout Procedure.

4. Developer Housing 4A. Ensure that the Devel-

oper Housing is latched

securely.

4B. Check the mag roll for

foreign material or contamina-

tion. Ensure that there is an

even coating of developer

material on the mag roll.

5. Defective or contaminated

LED Image Bar.

5. Check / clean the LED

Image Bar [9-21-5. ( PL 9.3)

6. Contaminated Erase

Lamp.

6. Clean with a lint free cloth.

7. Media transport 7. Ensure that the gap ( ADJ

8.4) is set correctly.

8. Heat Roll 8. Check for surface damage.

( PL 10.2)

9. Defective drum 9. Replace the drum ( REP

9.3).

Loading...

Loading...