01/02

3-17

8825/8830 Printer

PQ 17, PQ 17A

Print Quality

PQ 17 Smears PQ 17A Smudge

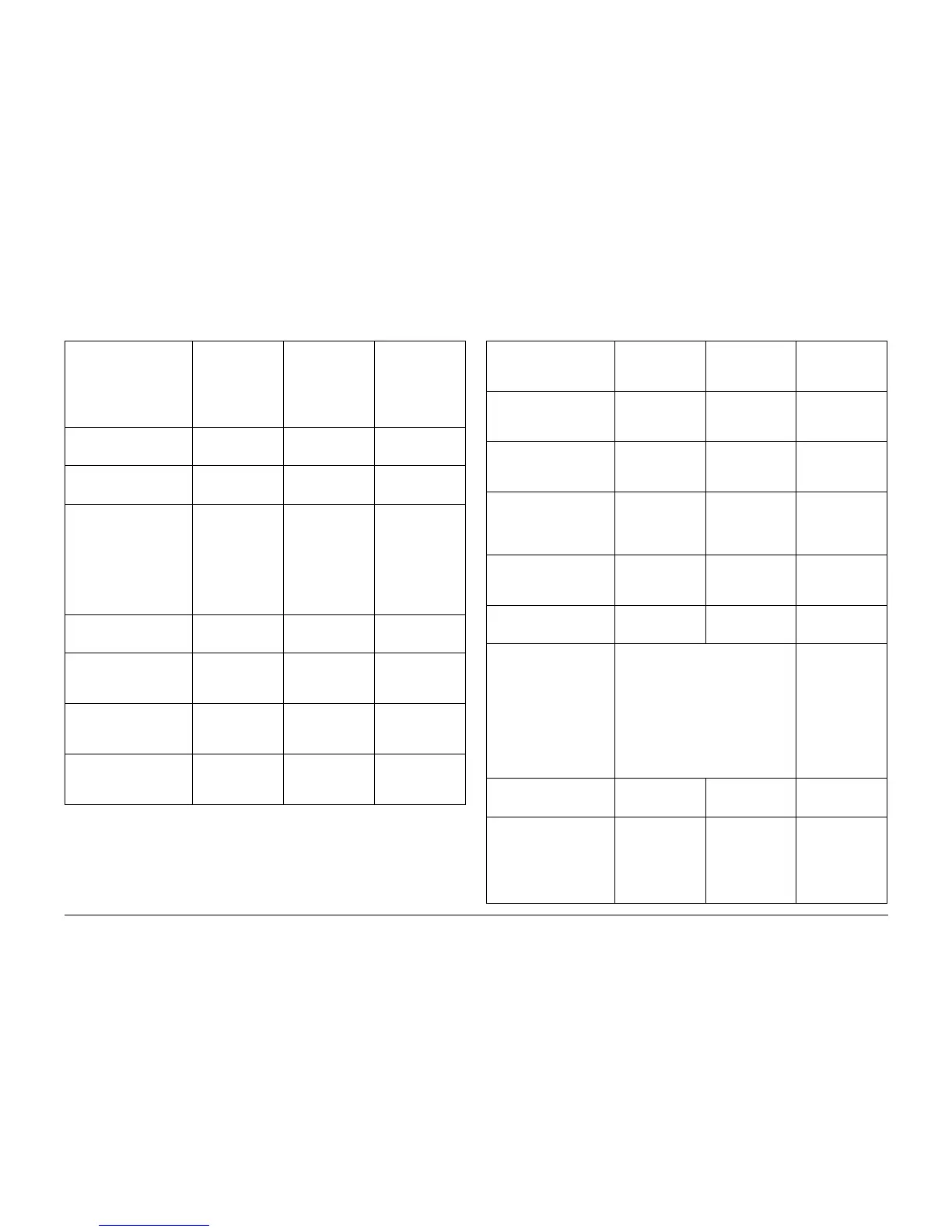

Table 1 Smears Symptom / Check

Symptom/ check

Areas of the image on the

print are blurred. This

occurs at the image transfer

area and is caused by a dif-

ference of speed between

the drum and the media.

Location of Smear Probable Cause Corrective Action

20 - 25 mm from the

Lead Edge of the

print

Transfer/Detack

Shield incorrectly

installed.

Check / replace (

PL 9.4)

40 - 50 mm from the

Lead Edge of the

print

Fabric Guide worn,

contaminated or

incorrectly installed.

Check / replace (

REP 8.9).

106 - 126 mm from

the Lead Edge of

the print

1. Worn (smooth)

Heat Roll ( PL 10.2)

2. Worn Contami-

nated Fabric Guide

( PL 10.3)

3. Pressure Plate A

installed incorrectly

or deformed ( PL

10.3).

Check / replace (

REP 10.2)

Check / replace (

REP 8.9)

3. Check / replace

( REP 8.5)

150 - 170 mm from

the Lead Edge of

the print

Pressure Plate B

installed incorrectly

or deformed.

Check / replace (

REP 8.5)

140 - 160 mm from

the Trail Edge of

the print

Cutter Check for loose

Cutter Drive Pulley,

Shim / replace ( PL

7.8)

66 - 86 mm from the

Trail Edge of the

print (Register Roll

Exit Smear)

Buckle Switch Enter [8-2 and

check for correct

operation ( PL 8.4)

Random smears Media Transport Ensure that the

Media Transport

gap ( ADJ 8.4) is set

correctly.

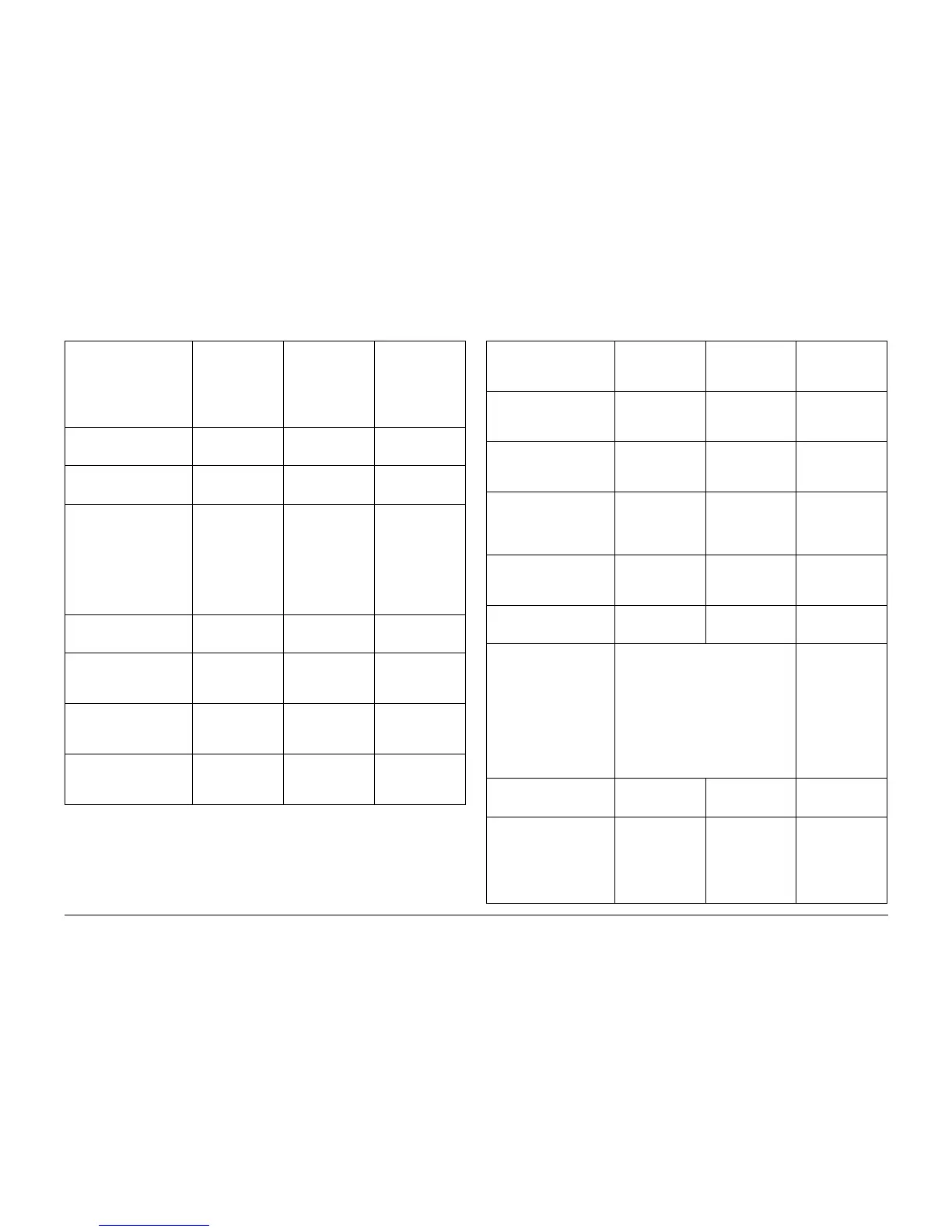

Table 1 Smudge Symptom / Check

Symptom/ check

A smudge is a displacement

of the toner image on the

drum or the media.

Location of

Smudge

Probable Cause Corrective Action

Perform GP 2, Image on

Drum to determine if the

Smudge occurs on the

media or the drum.

Media Heat Roll Check for a worn

(smooth) Heat Roll.

Replace ( REP

10.2)

Media Fabric Guide Check for a worn /

contaminated Fab-

ric Guide. ( REP

8.9)

Media Excessive media

curl (smudge

appears 100 mm

from lead or trail

edge)

Ask the customer to

replace the media.

Media Detack Corotron Check for contami-

nation or signs of

arcing. Clean /

replace ( PL 9.4)

Media Buckle Switch Check the Buckle

Switch for correct

operation ( PL 8.4)

Vellum Smudge is a special

defect that exhibits marginal

fusing fix. Toner can chip off

of the media and horizontal

lines are broken (image dis-

placement).

Combination of Vellum beam strength

and low Heat Roll drive force. (The

media is flexible enough that it buckles

between Pressure Plates A and B. The

toner then melts and partially sticks to the

Heat Roll. As the media enters the Pres-

sure Plate B, it flattens and the image is

displaced in front of it’s correct position.

The toner can also become a clump on

the media and easily chip off of the

media.)

Replace the Fabric

Guide ( REP 8.9)

and the Heat Roll (

REP 10.2).

Drum Mechanical interfer-

ence with the image

on the drum

Check for interfer-

ence.

Drum Buildup of devel-

oper material on the

lower extrusion of

the developer hous-

ing rubbing the

developed image

on the drum.

Push excess devel-

oper material back

into the housing.

Loading...

Loading...