16. FLM liquid cooling circuit

16. FLM LIQUID COOLING CIRCUIT

About this chapter

This chapter describes how to diagnoses and to maintain the liquid cooling circuit of the FLM projector.

WARNING: All procedures in this chapter may only be performed by “qualified service technicians” .

WARNING: All actions performed on the liquid cooling circuit should occur in ambient conditions (25°). The

projector should have sufficiently cooled down (minimum 2 hours).

WARNING: Do not change the air pressure of a calibrated liquid cooling circuit (see marking on pressure

vessel), unless stated explicitly in the servicing procedure.

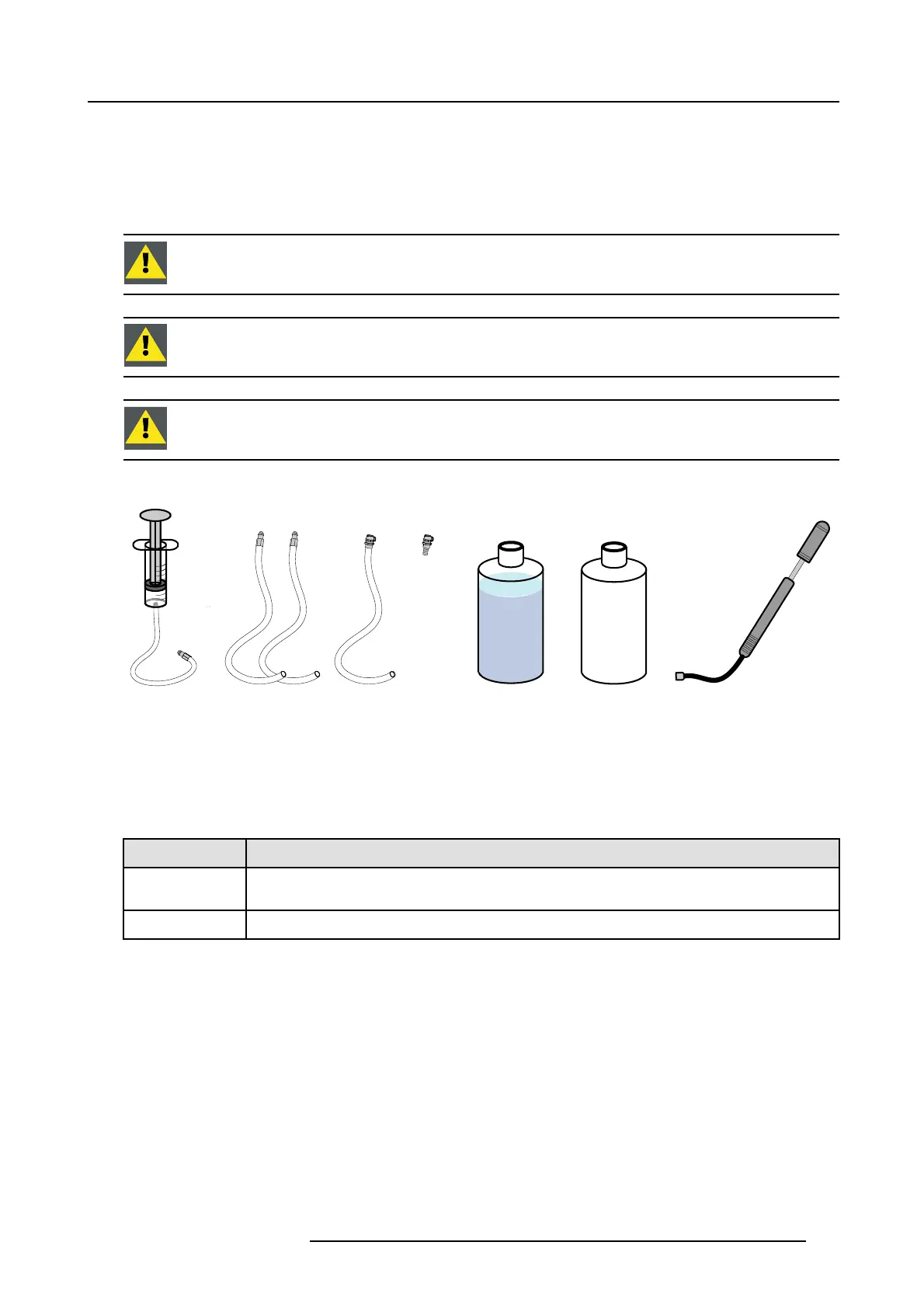

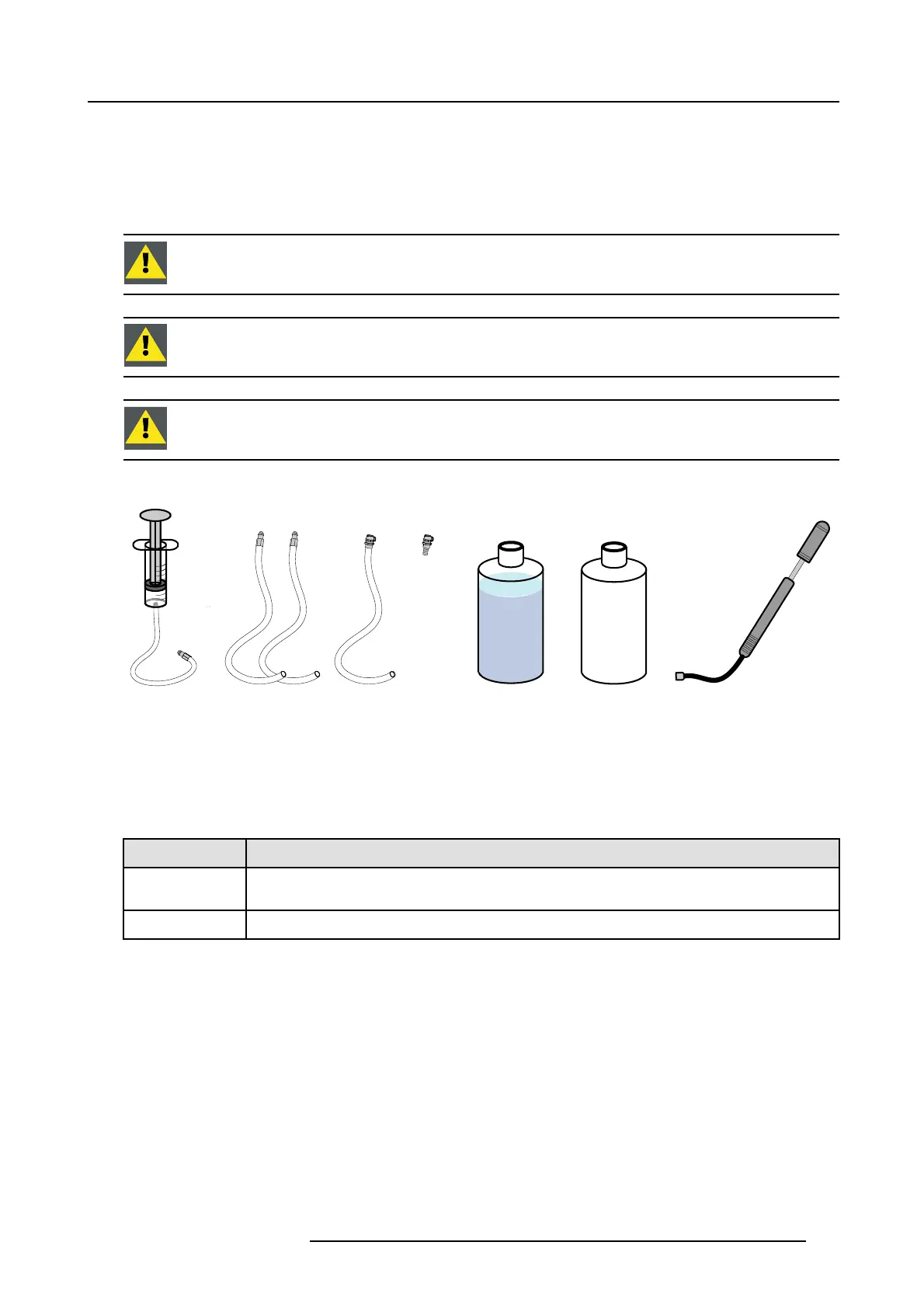

Tools used in the liquid cooling servicing procedures

1L

ABCD E F G

6

0

c

m

6

0

c

m

6

0

c

m

6

0

c

m

Image 16-1

A Syringe with plastic tube (60 cm) and male valved fitting.

B Two plastic tubes of 60 cm with male valved fitting.

C 60 cm plastic tube with female valved fitting.

D Female valved fitting (to create female/female valved fitting adaptor).

E Bottle with 1 liter cooling liquid.

F Empty bottle with a volume of 1 liter.

G Air pump with Shrader type air hose fitting.

Order info liquid cooling

Order number

Description

R395198K

Complete liquid cooling refill kit. Includes tubes, valved fittings, syringe, air pump, two plastic bottles of 1

liter filled with cooling liquid.

B1909086K

Four bottles of 1 liter filled with cooling liquid. (no additional tools)

Overview

• Safety

•In

troduction

• Diagnostics

• Pressure verification of the liquid cooling circuit

• Draining the liquid cooling circuit

• Filling the liquid cooling circuit

• Refreshing the liquid cooling circuit

• Expellin

g air from the liquid cooling circuit

• Pressurizing the liquid cooling circuit

• Calibrating the liquid cooling circuit

R59770072 FLM SERIES 19/03/2007

153

Loading...

Loading...