16. FLM liquid cooling circuit

16.10 Calibrating the liquid cooling circuit

To check if the pressure vessel is correctly calibrated you may connect the syringe with the cooling circuit

and measure the amount of liquid that is automatically expelled. The pressure would have dropped from 1 to

0 bar. The expelled amount of cooling liquid should be between 50 and 70 ml. Make sure that there are no air

bubbles in the syringe while doing this. Reinject the expelled liquid back into the circuit. The pressure would

hence return to 1 bar.

A calibrated liquid cooling circuit means that the ratio between the volume of cooling liquid in the circuit and

the volume of air in the pressure vessel is defined. This is achieved by first filling the vessel completely with

liquid consequently expelling air from the vessel. Secondly a predefined volume of cooling liquid is extracted

from the circuit. Finally the liquid cooling circuit has to be pressurized to 1 bar by pumping air into the vessel.

Make sure that all air is expelled from the liquid cooling circuit before starting the calibration procedure.

Necessary tools

• Half a meter of plastic tube with female valved fitting.

• Syringe connected with short tube with male valved fitting.

• Bottle with cooling liquid.

•Airpump.

• Cloths.

How to calibrate the liquid cooling circuit ?

1. Remove the valve cap of the pressure vessel and release the pressure.

Image 16-32

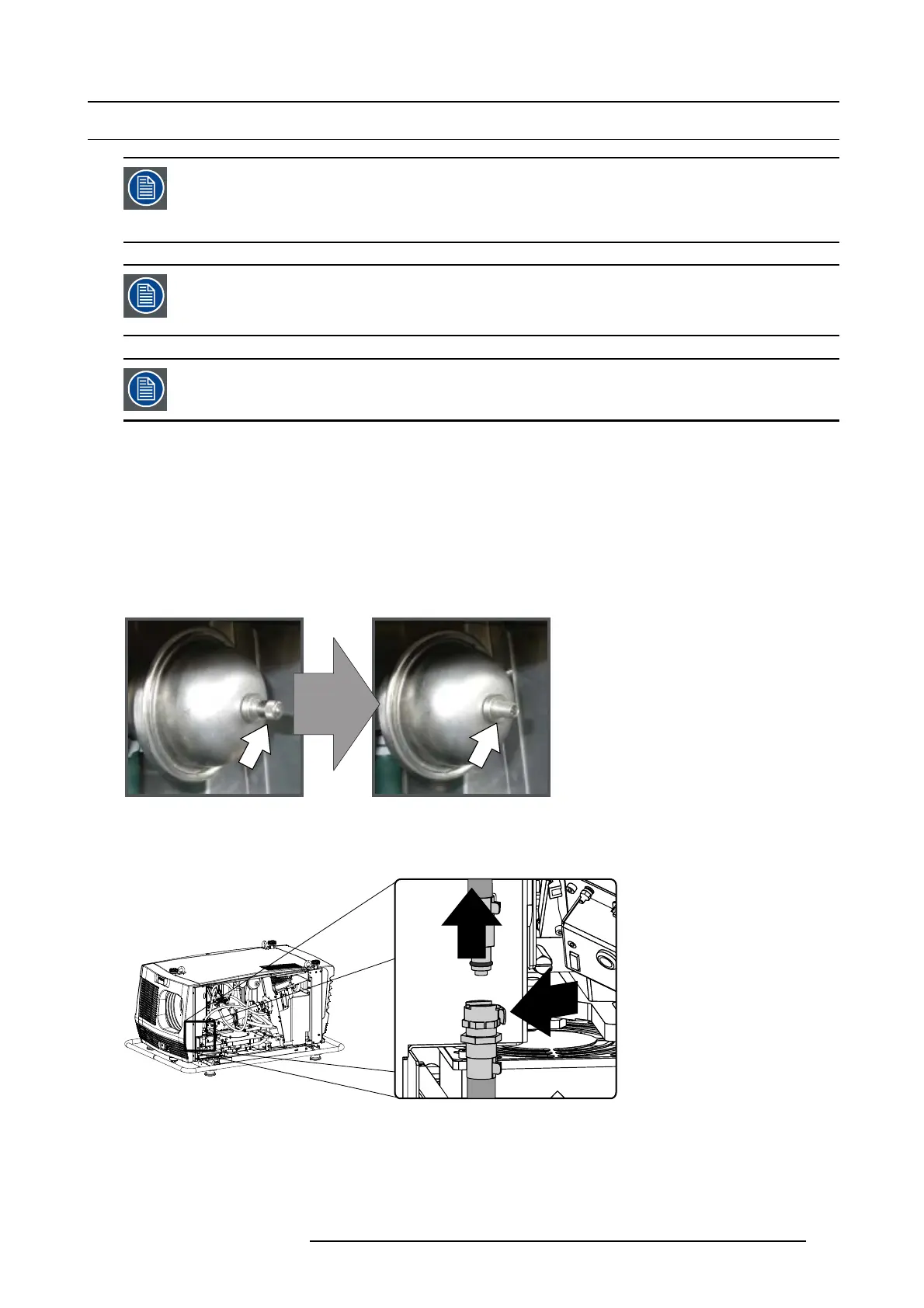

2. Interrupt the liquid cooling circuit by uncoupling the v

alved fitting at the heat exchanger if not yet done.

Tip: Sometimes a little cooling liquid will be spilled. Wrap a small cloth around the valved fitting while uncoupling to absorb

the spilled cooling liquid.

2

1

Image 16-33

3. Fill the syringe with cooling liquid as follows:

R59770072 FLM SERIES 19/03/2007

175

Loading...

Loading...