Section 7. Installation

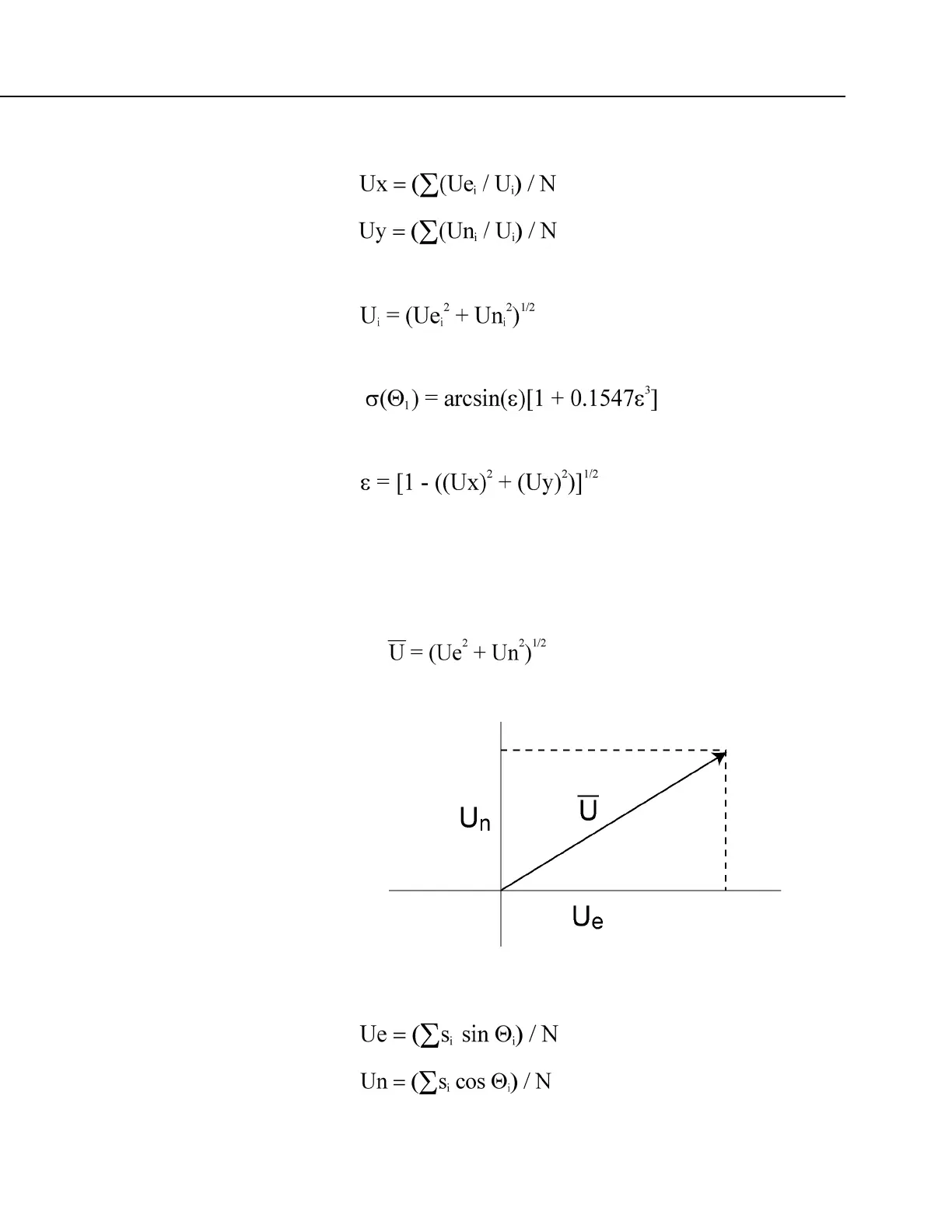

or, in the case of orthogonal sensors

where

Standard deviation of wind direction (Yamartino algorithm)

where,

and Ux and Uy are as defined above.

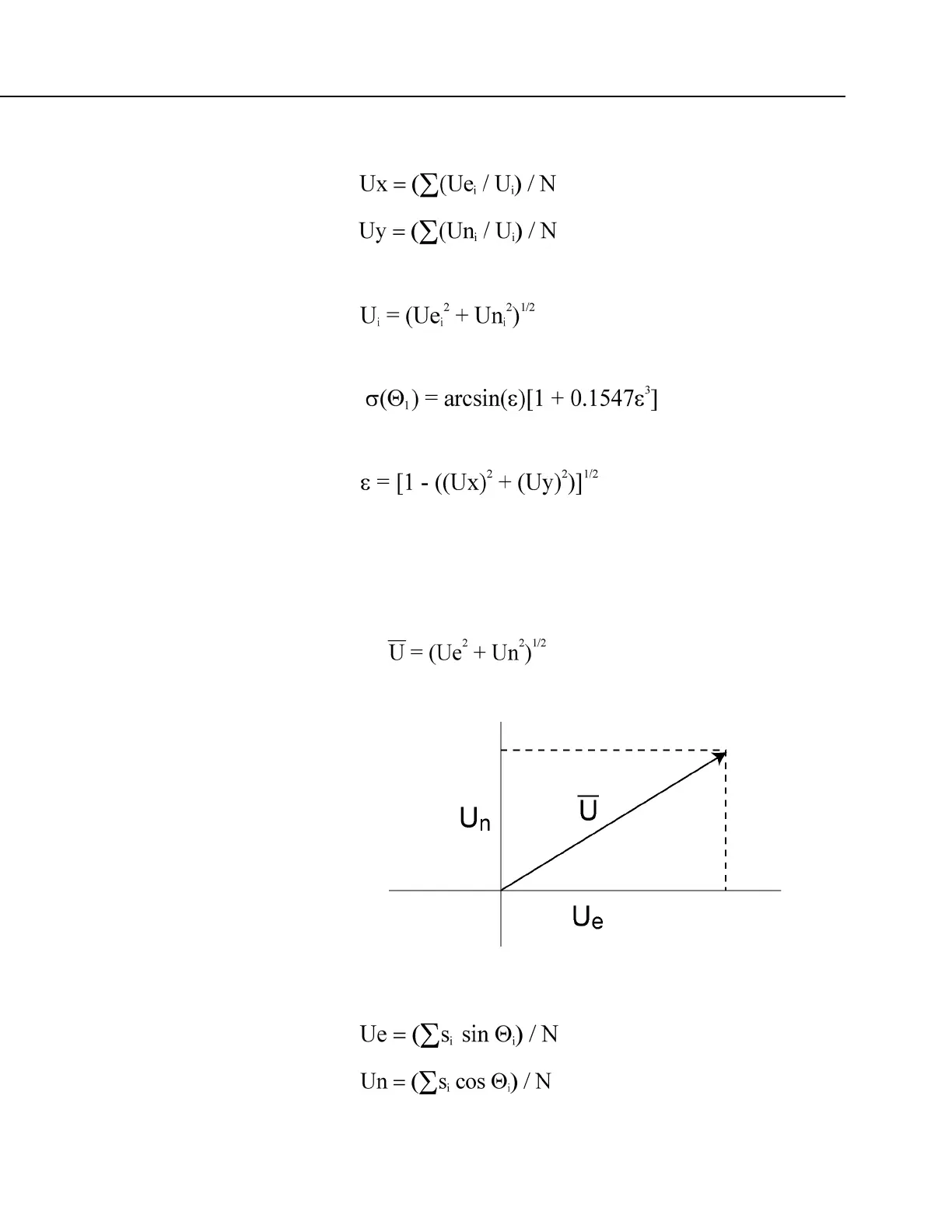

Mean Wind Vector

Resultant mean horizontal wind speed, Ū:

FIGURE 47: Mean Wind-Vector Graph

where for polar sensors:

Loading...

Loading...