Section 7. Installation

Scan(100,mSec,100,0)

'Measure Bridge Resistance

BrFull(Raw_mVperV,1,mV25,1,Vx1,1,2500,True ,True ,0,250,1.0,0)

'Calculate Strain for 1/4 Bridge (1 Active Element)

StrainCalc(microStrain,1,Raw_mVperV,Zero_mVperV,1,GF_Adj,0)

'Steps (1) & (3): Zero Calibration

'Balance bridge and set Zero_Mode = 1 in numeric monitor. Repeat after

'shunt calibration.

FieldCalStrain(10,Raw_mVperV,1,0,Zero_mVperV,Zero_Mode,0,1,10,0 ,microStrain)

'Step (2) Shunt Calibration

'After zero calibration, and with bridge balanced (zeroed), set

'KnownRes = to gage resistance (resistance of gage at rest), then set

'Shunt_Mode = 1. When Shunt_Mode increments to 3, position shunt resistor

'and set KnownRes = shunt resistance, then set Shunt_Mode = 4.

FieldCalStrain(13,MicroStrain,1,GF_Adj,0,Shunt_Mode,KnownRes,1,10,GF_Raw,0)

CallTable CalHist

NextScan

7.7.11.6.3 FieldCalStrain() Quarter-Bridge Shunt Example

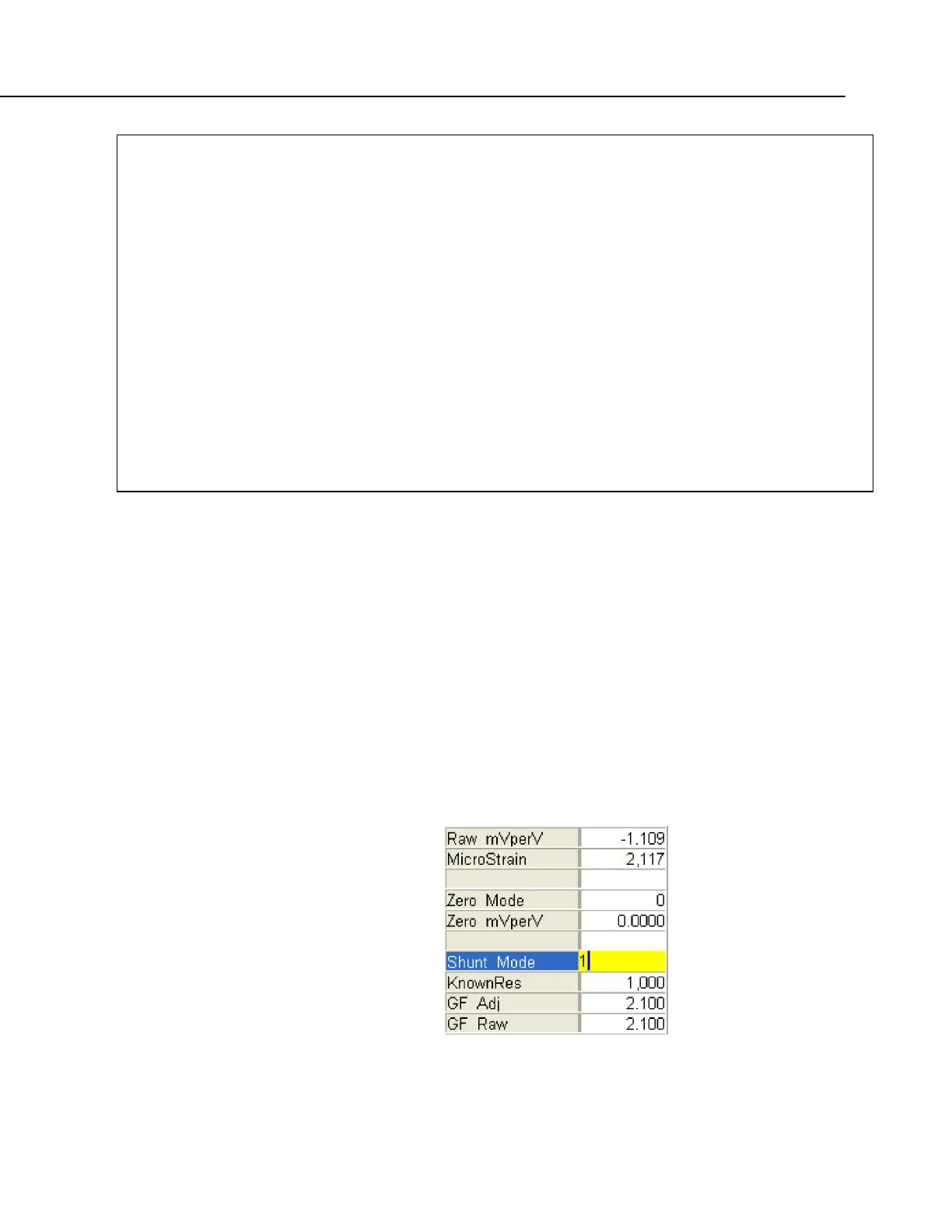

With CRBasic example FieldCalStrain() Calibration (p. 230) sent to the CR800, and

the strain gage stable, use the CR1000KD Keyboard/Display or software numeric

monitor to change the value in variable KnownRes to the nominal resistance of

the gage, 1000 Ω, as shown in figure Strain Gage Shunt Calibration Start

(p. 231).

Set Shunt_Mode to 1 to start the two-point shunt calibration. When Shunt_Mode

increments to 3, the first step is complete.

To complete the calibration, shunt R1 with the 249 kΩ resistor. Set variable

KnownRes to 249000. As shown in figure Strain Gage Shunt Calibration Finish

(p. 232),

set Shunt_Mode to 4. When Shunt_Mode = 6, shunt calibration is

complete.

FIGURE 60: Strain Gage Shunt

Calibration Start

Loading...

Loading...