MAINTENANCE AND SERVICING

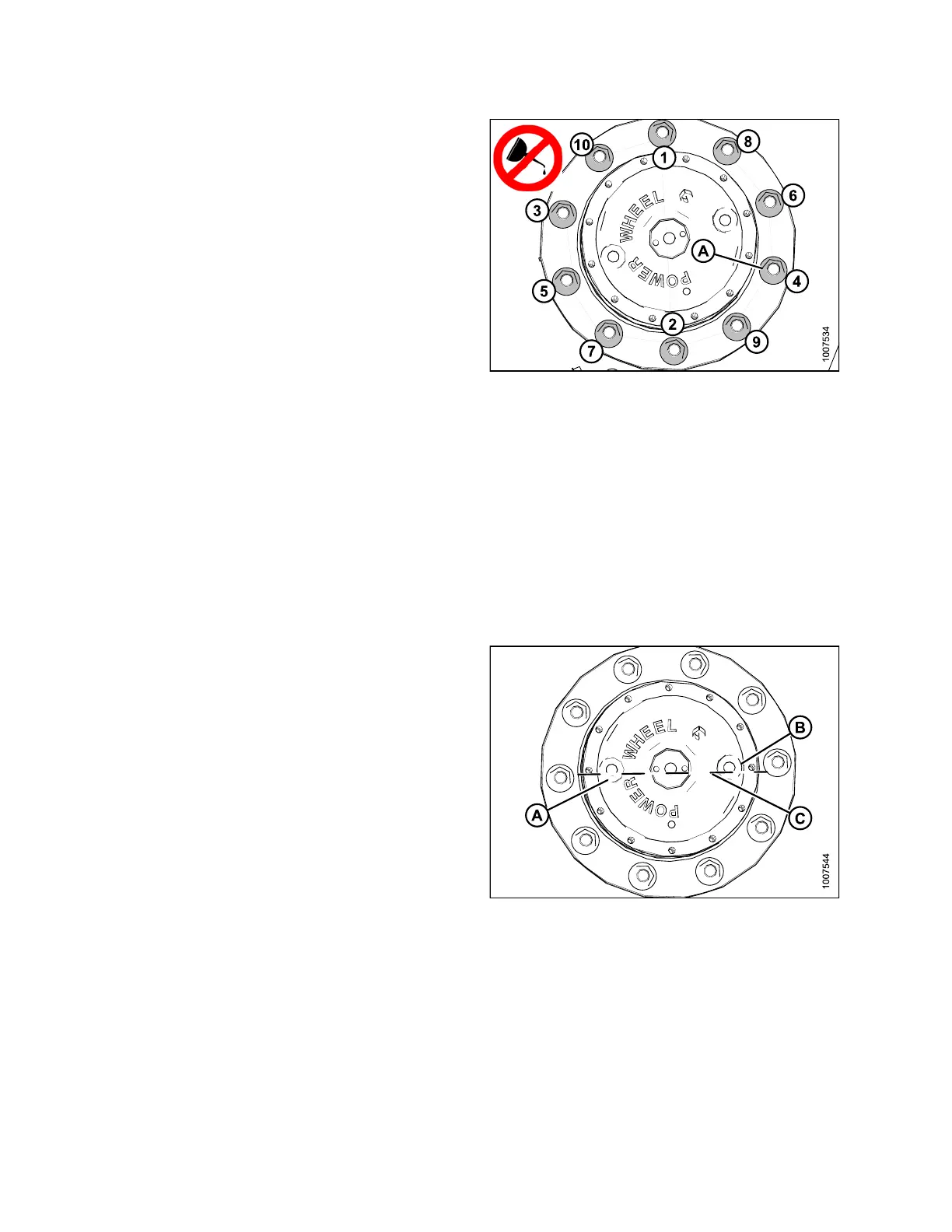

1. Tighten drive wheel nuts (A). Ensure nuts and studs

are dry with no lubricant or Never-Seez

®

compound.

Torque each to 375 lbf ft (510 N·m) using the tightening

sequence shown at right.

2. Repeat torque procedure every hour until two

consecut ive checks produc e no movement of the nuts.

Figure 5.192: Wheel Drive Assembly

Lubricating Wheel Drive

Refer to th

ese procedures to lubricate the wheel drive.

• Checking W

heel Drive Lubricant Level, page 300

• Adding Wh

eel Drive Lubricant, page 300

• Changing

Wheel Drive Lubricant, page 302

Checking

Wheel Drive Lubricant Level

Check the wheel drive lubricant level every 200 hours or annually.

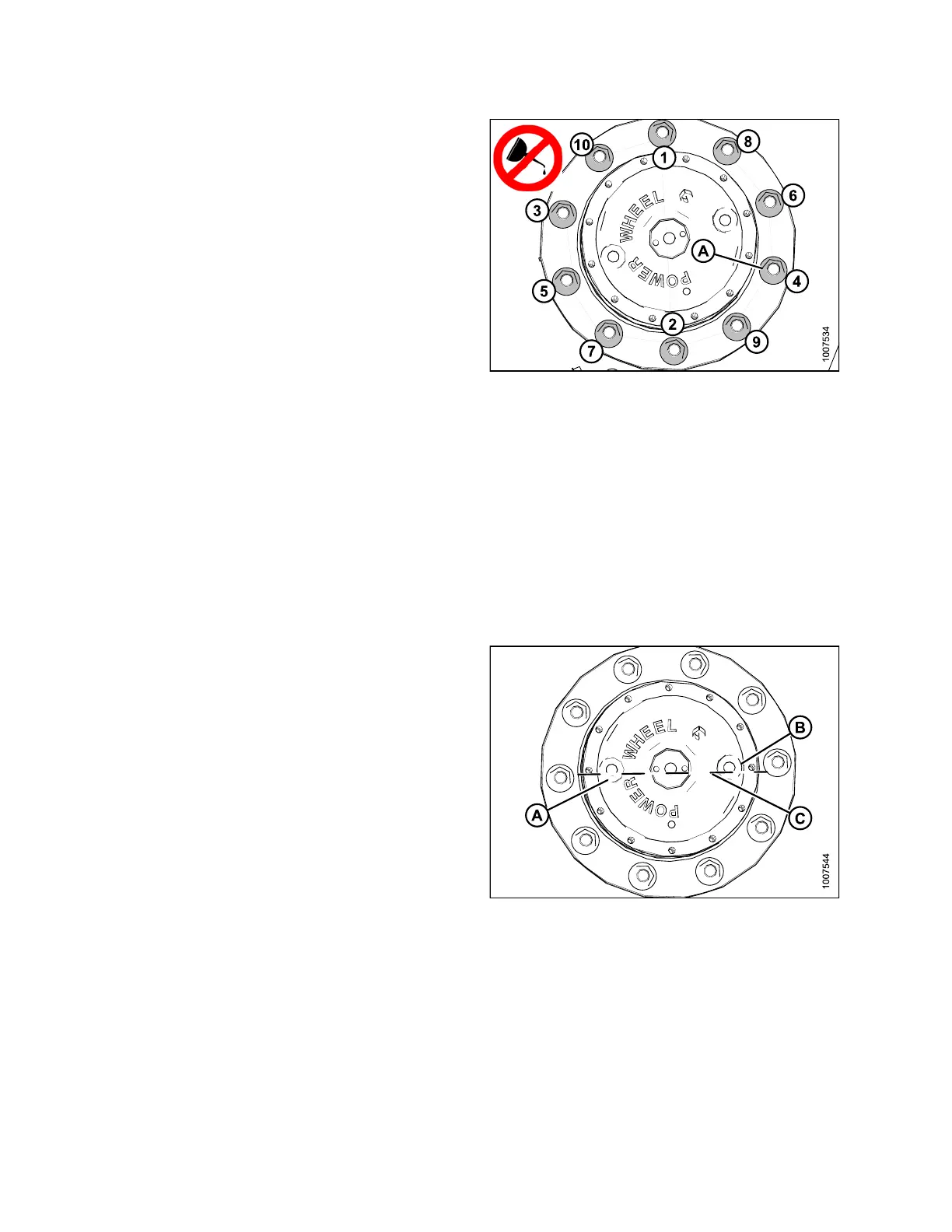

1. Park the windrower on level ground.

2. Position windrower so that plugs (A) and (B) are

horizontally aligned with the center (C) of the hub.

3. Remove plug (A) or (B). The lubricant should b e visible

through the port or running out slightly. If lubricant

needs to be added, Refer to Add ing Wheel Drive

Lubricant, page 300.

NOTE:

The type of lubricant used after the fi rst lubricant change

is different from the factory supplied lubricant.

4. Reinstall plugs and tighten.

Figure 5.193: Wheel Drive Assembly

Adding Wheel Drive Lubricant

NOTE:

Do NOT mix lubricants of different brands or characteristics.

169890 300 Revision A

Loading...

Loading...