Section 00: GENERAL INFORMATION

PA1553

9

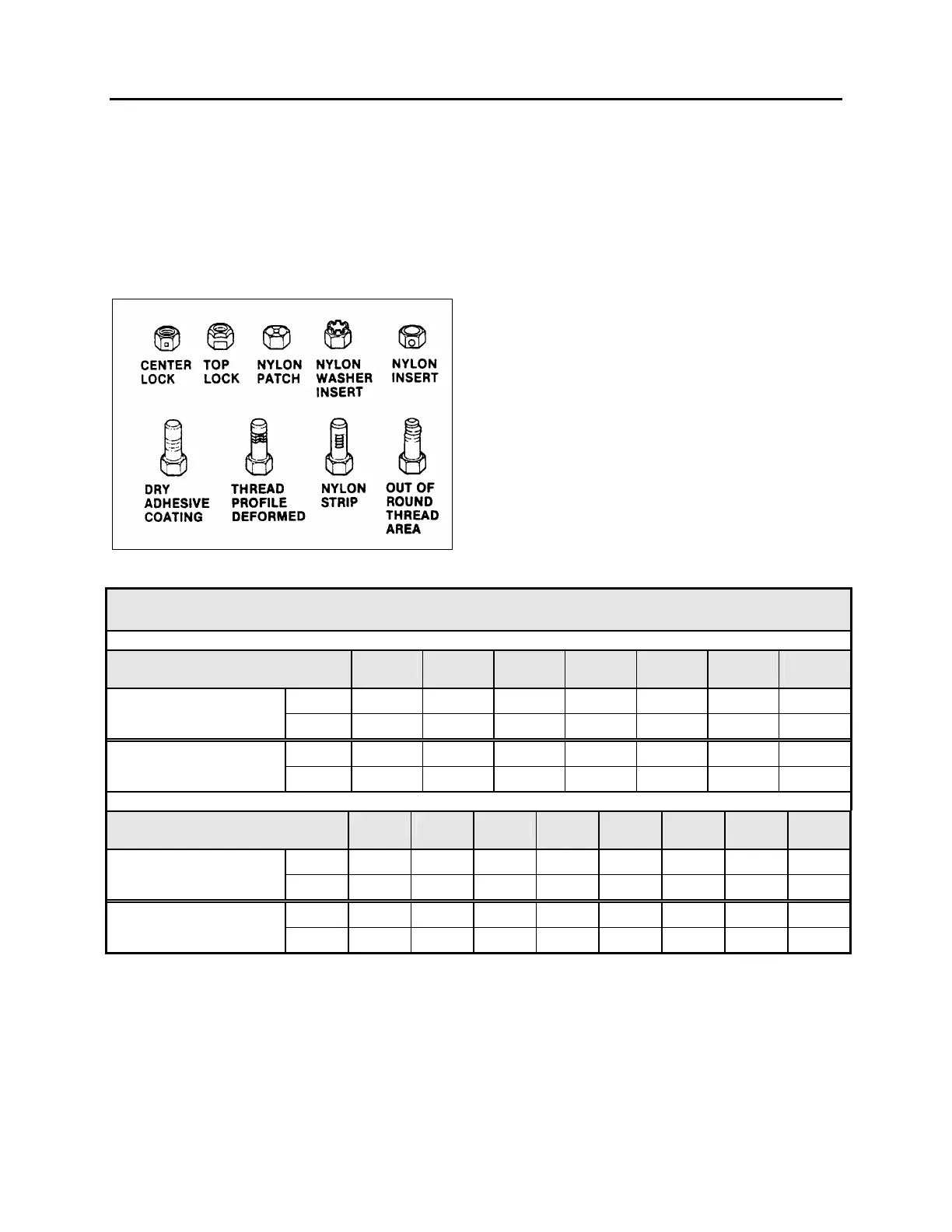

5.1 SELF-LOCKING FASTENERS

A self-locking fastener is designed with an

interference fit between the nut and bolt threads.

This is most often accomplished by distortion of

the top thread of an all-metal nut or bolt or by

using a nylon patch on the threads. A nylon

insert or the use of adhesives may also be used

as a method of interference between nut and

bolt threads (Fig. 12).

FIGURE 12 : SELF-LOCKING FASTENERS 00004

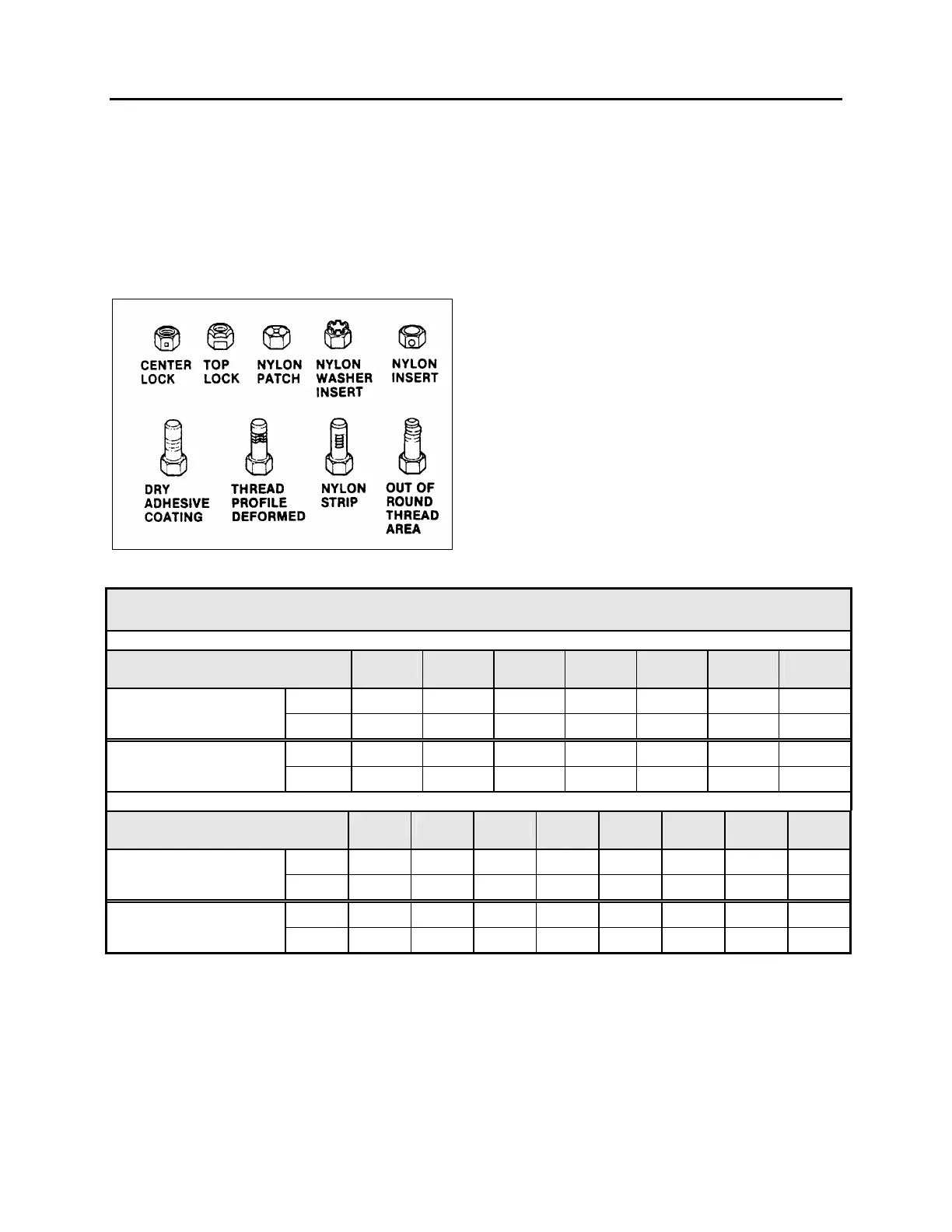

5.2 RECOMMENDATIONS FOR REUSE

Clean, unrusted self-locking fasteners may be

reused as follows:

a) Clean dirt and other foreign matter from

the fastener;

b) Inspect the fastener to ensure there is no

crack, elongation, or other sign of fatigue

or overtightening. If there is any doubt,

replace with a new self-locking fastener of

equal or greater strength;

c) Assemble parts and hand start fastener;

d) Observe that, before the fastener seats, it

develops torque per the chart in table two.

If there is any doubt, replace with a new

self-locking fastener of equal or greater

strength;

e) Tighten the fastener to the torque

specified in the applicable section of this

manual;

Fasteners which are rusty or damaged should

be replaced with new ones of equal or greater

strength.

SELF-LOCKING FASTENER TORQUE CHART

METRIC

6 & 6.3 8 10 12 14 16 20

NUTS AND Nm 0.4 0.8 1.4 2.2 3.0 4.2 7.0

ALL-METAL BOLTS Lbf-in 4.0 7.0 12 18 25 35 57

ADHESIVE OR NYLON Nm 0.4 0.6 1.2 1.6 2.4 3.4 5.6

COATED BOLTS Lbf-in 4.0 5.0 10 14 20 28 46

US STANDARD

.250 .312 .375 .437 .500 .562 .625 .750

NUTS AND Nm 0.4 0.6 1.4 1.8 2.4 3.2 4.2 6.2

ALL-METAL BOLTS Lbf-in 4.0 5.0 12 15 20 27 35 51

ADHESIVE OR NYLON Nm 0.4 0.6 1.0 1.4 1.8 2.6 3.4 5.2

COATED BOLTS Lbf-in 4.0 5.0 9.0 12 15 22 28 43

5.3 SIX LOBED SOCKET HEAD

Six lobed socket head (Torx) fasteners are used

in some applications on vehicles covered in this

manual. The tools designed for these fasteners

are available commercially. However, in some

cases, if the correct tool is not available, a hex

socket head wrench may be used.

Loading...

Loading...