Section 22: HEATING AND AIR CONDITIONING

PA1553

41

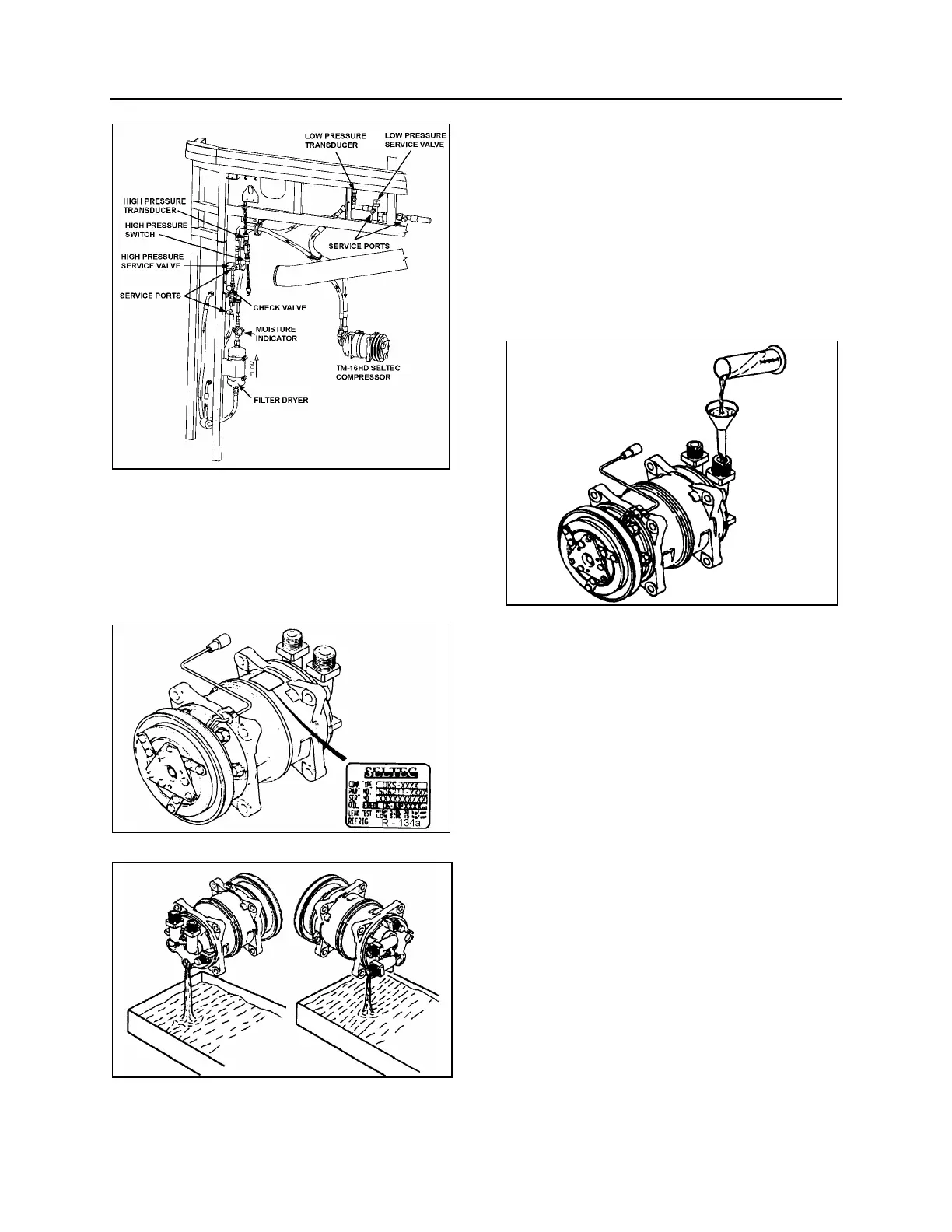

FIGURE 43: SMALL A/C SYSTEM REAR COMPONENTS

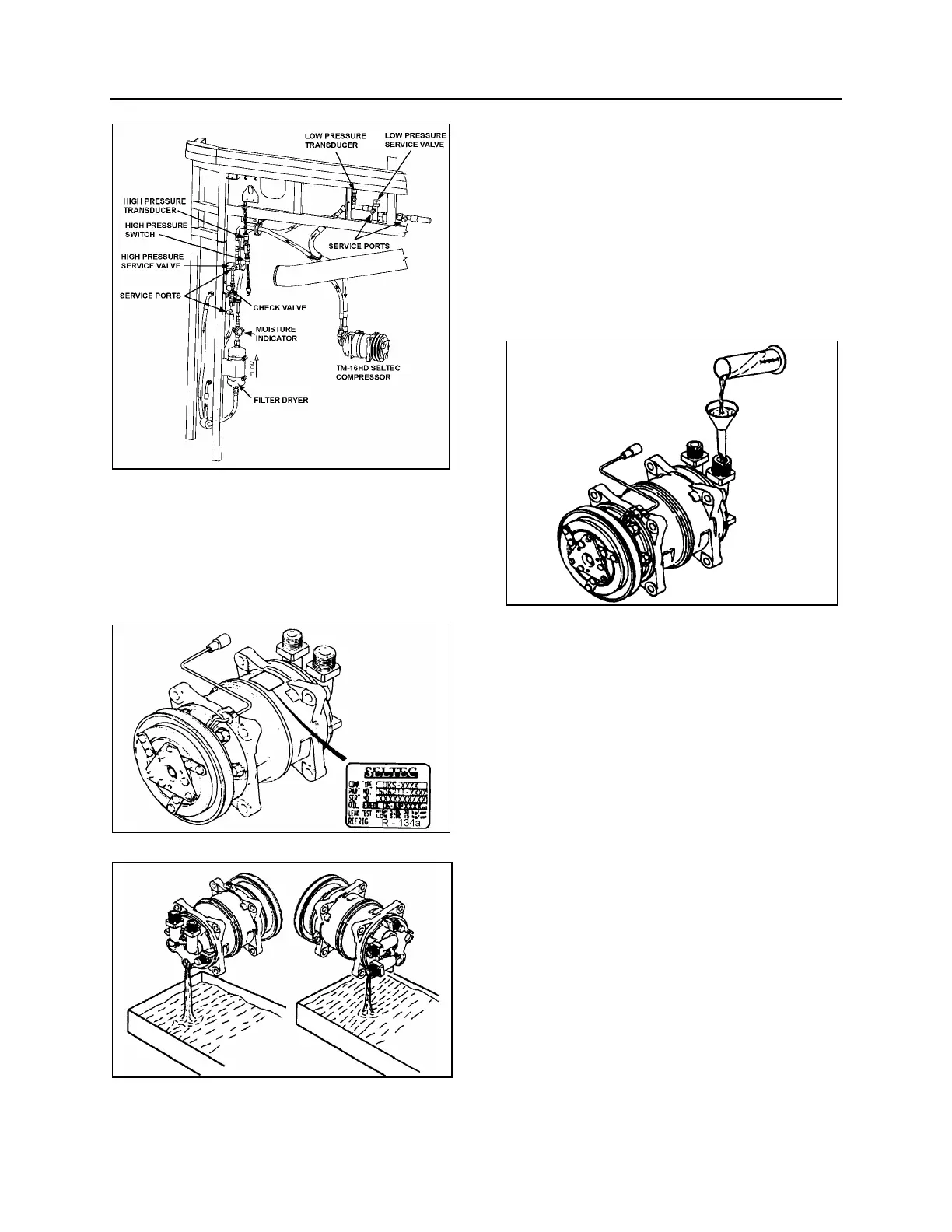

10.6 COMPRESSOR OIL CHANGE

Each compressor is delivered filled with the

specified quantity of compressor oil, depending

on the type of air conditioning system. A label

describing the amount/type of compressor oil is

attached to the compressor.

FIGURE 44: COMPRESSOR OIL LABEL

FIGURE 45: DRAINING THE OIL

* Check oil for contamination. Refer to

PARAGRAPH 10.8: “COMPRESSOR OIL

CONTAMINATION”.

* Tighten the oil drain plug with a new o-ring

lightly coated with clean compressor oil to

specified torque.

Torque: 13-15 Nm (9.4-10.8 Lbf-ft)

* Add new compressor oil through the

suction-side connector with the amount

specified on the label (180 ml).

FIGURE 46: ADDING NEW COMPRESSOR OIL

10.6.1 Evacuating System Before Adding

Refrigerant (Small System)

When a system has been opened for repairs,

change the filter dryer and evacuate the system.

XL2 MTH equipped with a small system must

use high-pressure service port located on the

other side of check valve and low-pressure port

located alongside rear truss. (Figs. 42 and 43). It

would be good practice to open solenoid valve.

1. Connect two hoses equipped with a micron

gauge between the high-pressure service

port, the low-pressure service port and the

vacuum pump.

2. With the unit service valves open and the

vacuum pump valves open, start the pump

and draw the manifold and hoses into a

very deep vacuum (700 microns).

3. Close manifold valve

4. Shut down the vacuum pump.

5. Check to insure that vacuum holds. (If the

pressure continues to rise, it indicates a

leak or moisture in the system).

Loading...

Loading...