Section 26: XLII SLIDE-OUT

PA1553

15

To remove, loosen the set screw and release the

locking collar using channellock pliers or a small

pipe wrench.

11 LINEAR BEARING

11.1 MAINTENANCE

Make every effort not to allow dust and foreign

objects to enter inside the linear bearing.

The linear bearings are pre-lubricated and no

subsequent lubrication is required due to the

very low demanding use of the slide-out system.

11.2 REPLACEMENT &

ADJUSTMENT

1. Remove the slide-out from the vehicle

(removal must be performed according to

the Slide-Out Removal Procedure. Ask to

your Prevost service representative).

2. Disconnect the jaw coupling on the side of

the linear bearing being replaced (refer to

section 8).

3. Dismount the blue flange bearing.

4. From the mechanism access panel, remove

the retaining screws A, B, C & D (see figure

22).

5. Now, you have access to the linear bearing

mounting bolts if you turn its support up side

down. Dismount the linear bearing and

install the new one.

6. Tighten the mounting bolts in a criss-cross

pattern to a torque of 60 ft-lb.

7. Reinstall the support plate, retaining screws,

blue flange bearing and reengage the jaw

coupling. Refer to the specific procedures.

11.3 LEVEL & TILT ADJUSTMENT

Leveling of the slide-out is done by changing the

linear bearing support plate height using the

leveling screws 1, 2, 3, 4 (figure 22). When

proper level is attained, the retaining screws A,

B, C & D maintain the support plate seated on

the leveling screws. Also, the retaining screws

prevent the slide-out from tipping inside the

vehicle when it is retracted.

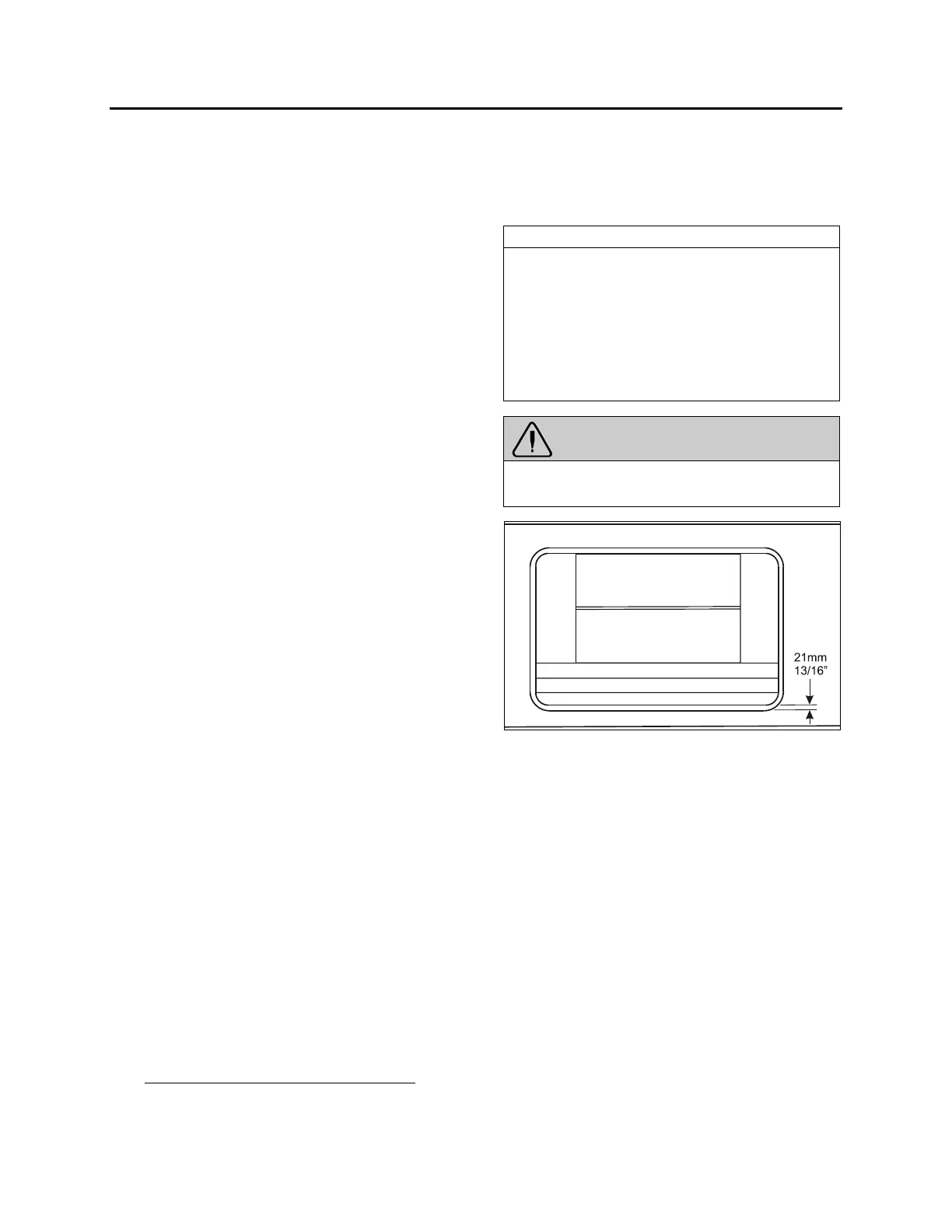

The slide-out is slightly tilted. When retracting,

the upper "in limit" stoppers touch first

the

vehicle structure, followed by the lower "in limit"

stoppers. Tilt adjustment is done by changing

the linear bearing support plate inclination using

the leveling screws 1 & 2 as pivot and 3 to adjust

the angle (figure 22).

11.3.1 Procedure

NOTE

For the front slide-out, the front linear

bearing leveling screws are accessible from

the access panel located over the front wheel

while the rear linear bearing leveling screws

are accessible from the access panel in the

evaporator compartment. For the rear slide-

out, access the linear bearing from under the

bed structure or the radiator compartment.

WARNING

The slide-out must be retracted when the level

and tilt adjustment is performed.

FIGURE 21: SLIDE-OUT LEVEL ADJUSTEMENT

Before proceeding with the level and tilt

adjustment, check the following conditions:

• The slide-out is retracted;

• The 2 lower “in limit” stoppers are perfectly

adjusted, that means that the lower edge

of the slide-out outer panel is flush with

the vehicle body when retracted;

• The 2 upper “in limit” stoppers are

removed from the slide-out (see

section1.2).

1. Loosen the blue flange bearings mounting

screws (FIGURE 13).

2. For front slide-out only, loosen the two

plastic plates mounting screws along the

shafts (FIGURE 13).

3. With the lower edge of the slide-out outer

panel flush with the vehicle body, adjust the

Loading...

Loading...