10

2

Mounting area

(continued)

Support surface diameters

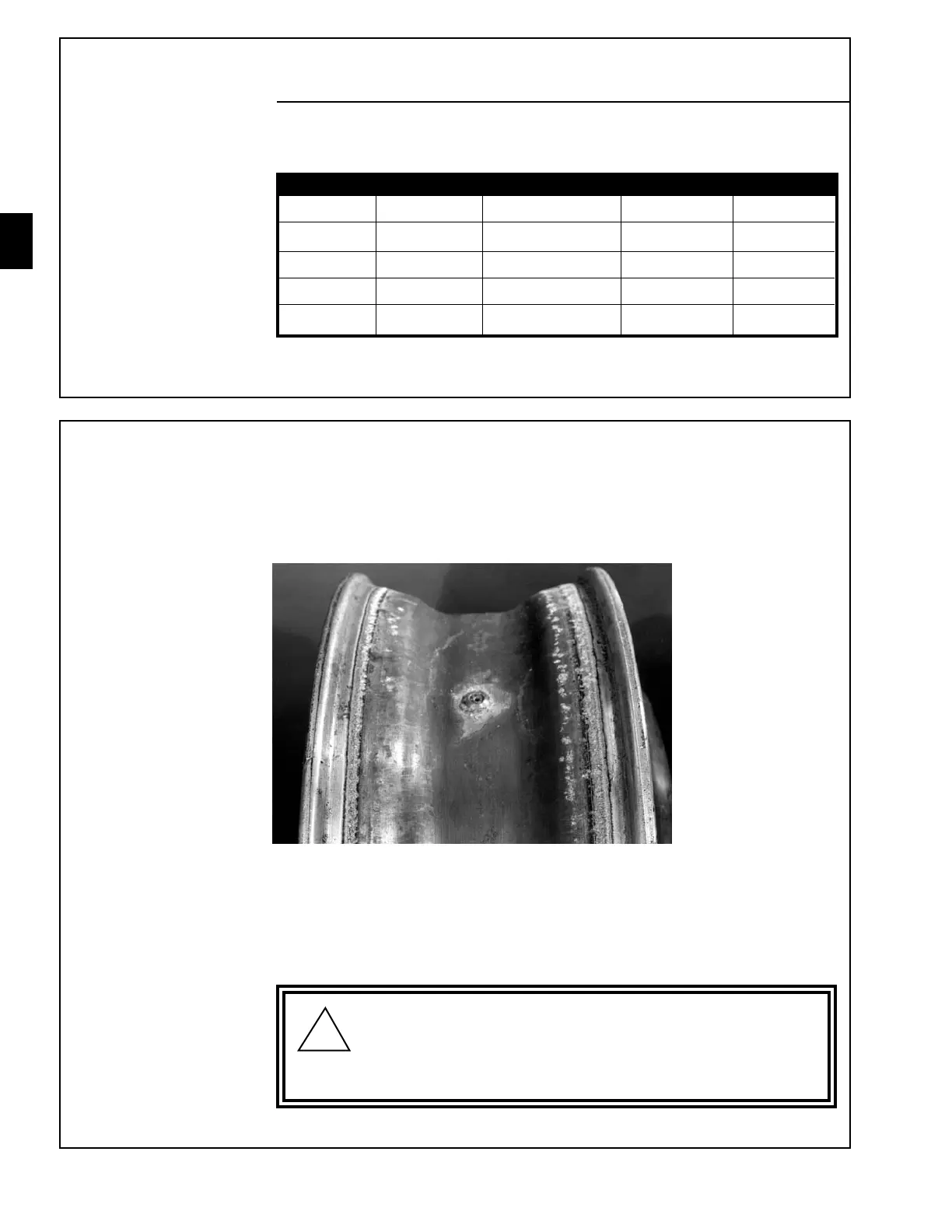

Support surface (backup diameter) should be flat to the diameter recommended

on the chart below:

Number of Bolts Bolt Circle Mounting Type Backup Diameter Thread Size

10 11.25 inch U.S. Stud pilot 13.2-13.5 in. .750/1.125 in.

10 285.75mm Hub pilot 13.2-13.4 in. 22mm

10 335mm Hub pilot 15.0-15.2 in. 22mm

8 275mm U.S. Stud pilot 13.2-13.5 in. 22mm

8 275mm ISO Hub pilot 12.4-12.6 in. 20mm

Corrosion

2-6

Due to aluminum's natural resistance to corrosion, Alcoa aluminum disc wheels

do not need to be painted for most operating conditions. However, certain

environments can lead to corrosion. Some of these are: salt, chloride compounds

used for snow removal and highly alkaline materials. If the air used to fill

tubeless tires, or the tire itself, is not dry, the areas of the wheel under the tire

can corrode severely.

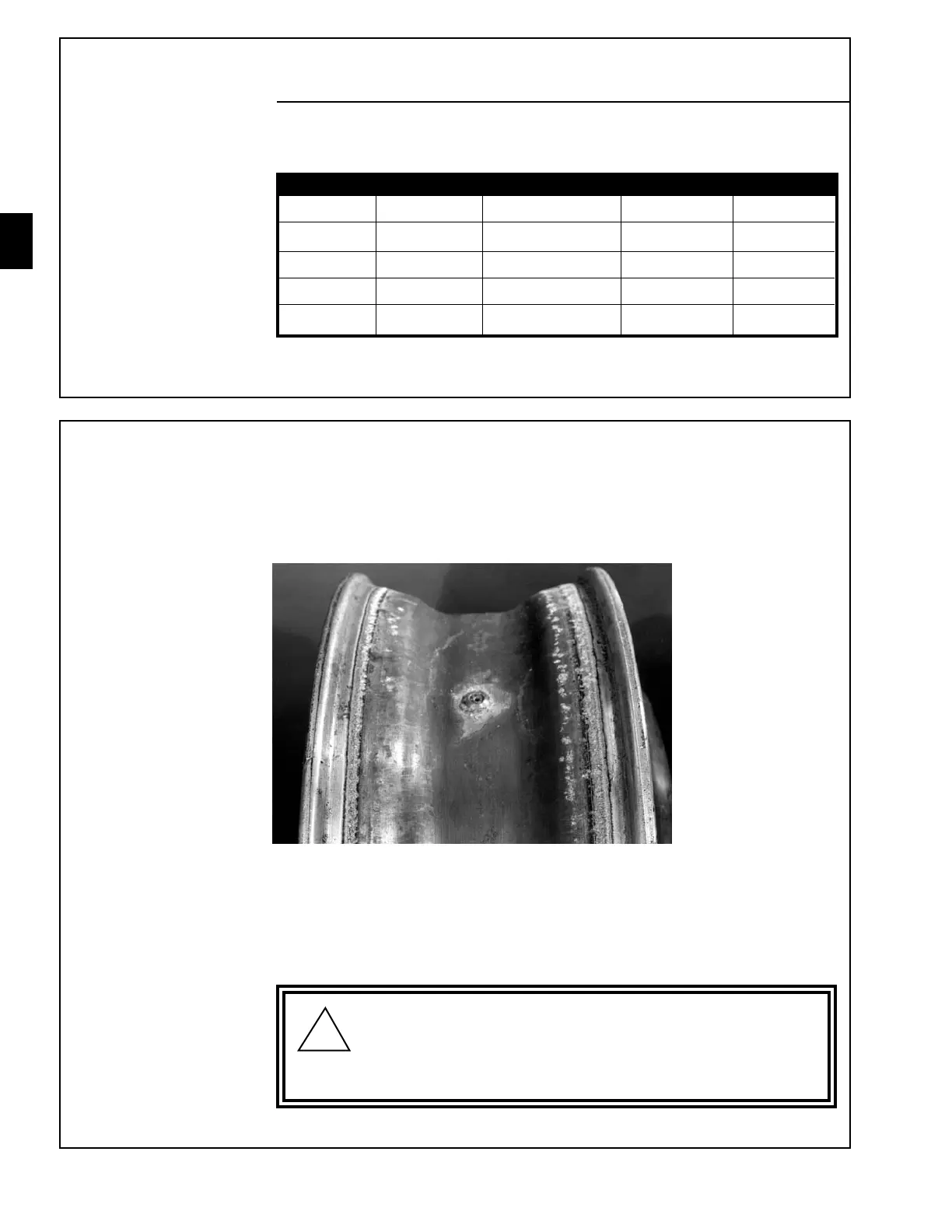

Bead seat and valve stem corrosion often are caused by entrapped moisture

which contains corrosive elements. Mild corrosion should be removed thoroughly

by wire brush and the rim protected with a coating of non-water-based lubricant

(see 3-1, page 18). Remove any severely corroded wheel from service.

CAUTION The use of liquid tire balancers or sealants in Alcoa wheels

may cause extremely rapid corrosion of the wheel rim surface.

Severely corroded wheels are unsuitable for service. Alcoa wheels corroded

by the use of liquid tire balancers or sealants will not be replaced under

the Alcoa limited warranty.

CAUTION

!

Loading...

Loading...