Section 12: BRAKE AND AIR SYSTEM

PA1553

8

8.6 MAINTENANCE

Inspect all lines for cuts, swelling, kinks or other

damage or deterioration. Check for lines being

pinched by other components. Retaining clips

and ties must be in place.

Any support or bracket should be in good

condition and mounted firmly in position. Hose

spring guards should be in usable condition and

not distorted. Particular attention should be

given to long lines. Any supporting component

(clips, ties, grommets, etc.) must be secured to

prevent against unnecessary vibration and

eventual loosening of connection. Any detected

leak should be repaired. Be sure nylon lines are

not near areas of intense heat. Check for any

missing grommets or loose material where

chafing or cutting may occur. Replace with new

material as required. In general, lines should be

securely located in position and free from any

binding condition which would hinder air flow.

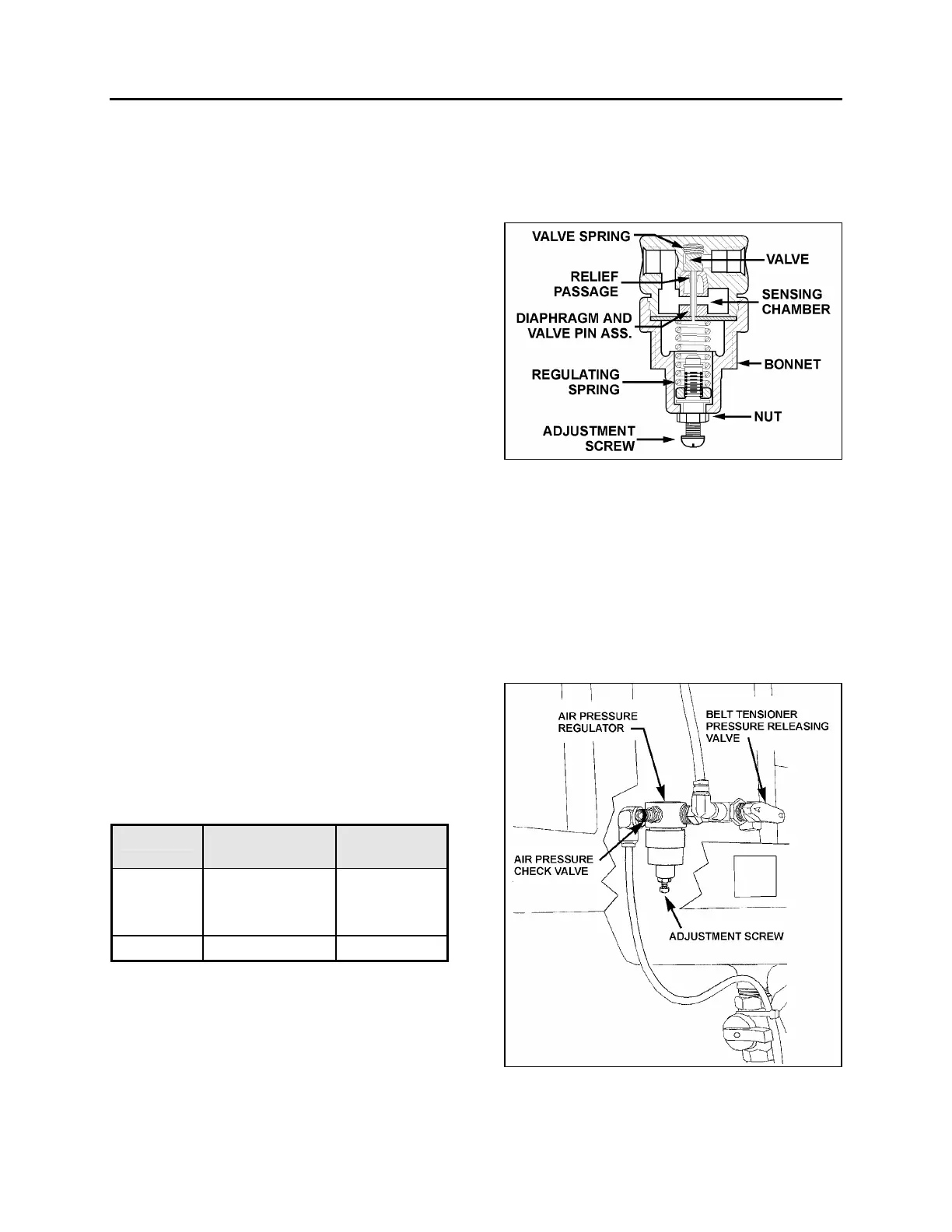

9. PRESSURE REGULATING VALVES

There is one pressure regulator for the belt

tensioners, and an optional one installed on

vehicles equipped with the Allison transmission

output retarder.

The belt tensioner pressure regulating valve is

located in the engine compartment above the

doors and is used to limit the air pressure in belt

tensioners to 50 ± 2 psi (345 ± 15 kPa) for WE

and W0 MTH and to 45 ± 2 psi (310 ± 15 kPa)

for W5 MTH (Fig. 7).

The optional regulator is located above the rear

junction box in the engine compartment

(accessible through the engine R.H. side door).

It is used for transmission retarder and should

be adjusted to 80 ± 3 psi (550 ± 20 kPa).

Air Pressure

(psi)

Air Pressure

(kPa)

Belt

Tensioner

Series 60

50 (WE & W0)

45 (W5)

Series 60

345

310

Retarder 80 ± 3 550 ± 20

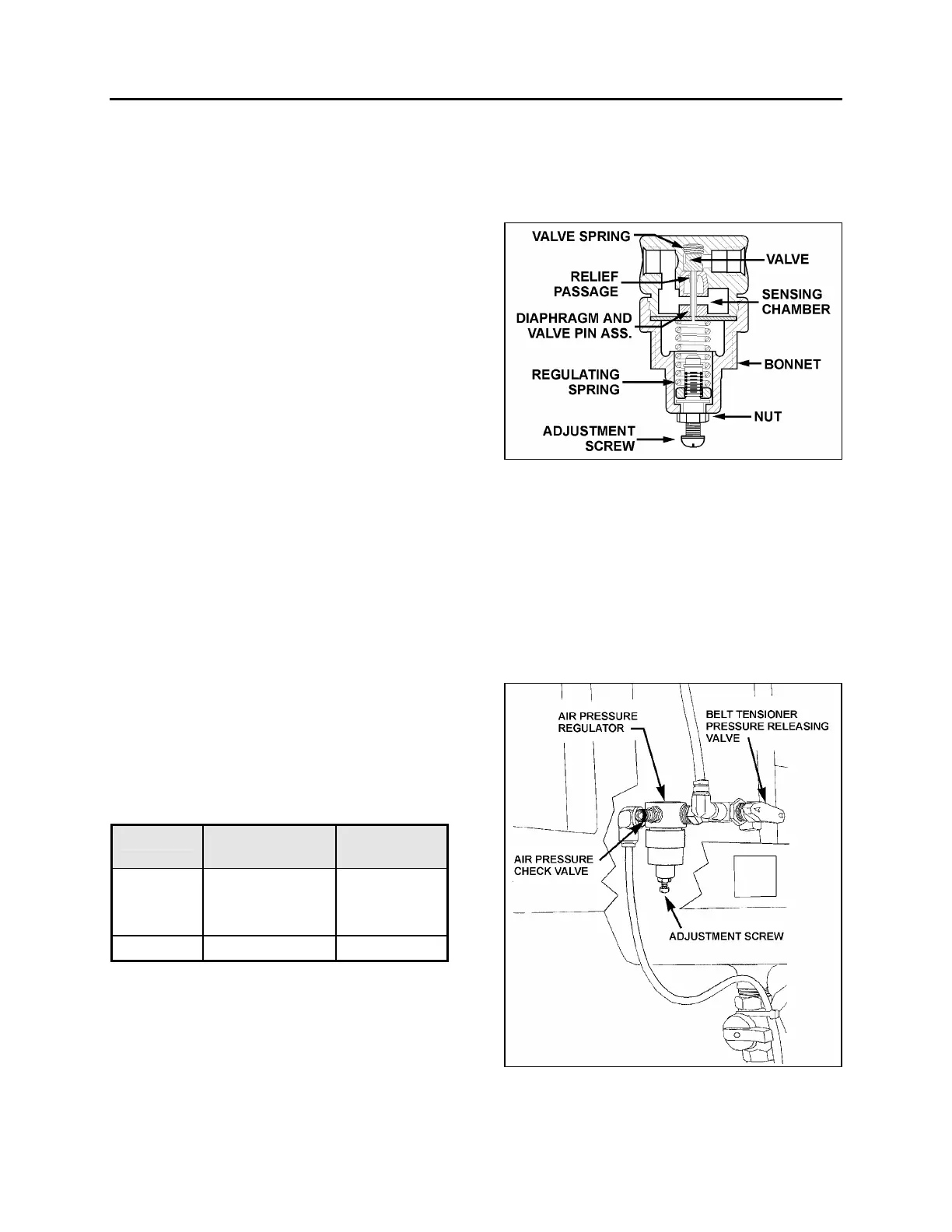

9.1 MAINTENANCE

Every 100,000 miles (160 000 km) or once every

two years, whichever comes first, disassemble

the regulating valve and wash all metal parts in

a cleaning solvent (Fig. 6). Examine the

diaphragm; if cracked, worn or damaged,

replace with a new one. If the valve is

excessively grooved or pitted, it should be

replaced. Replace any other part that appears

worn or damaged. After reassembly, adjust to

the specified pressure setting and check for air

leakage.

FIGURE 6: AIR PRESSURE REGULATING VALVE 12141B

9.2 PRESSURE SETTING PROCEDURE

Remove the dust cap from the pressure check

valve (Fig. 7). Attach a pressure gauge at this

port and check the pressure reading. If the

pressure reading is incorrect, adjust as follows:

1. Loosen the locking nut, turn the adjustment

screw counterclockwise to decrease pres-

sure by approximately 10 psi (70 kPa) below

the required pressure.

FIGURE 7: AIR PRESSURE REGULATOR 12200

Loading...

Loading...