Section 26: XLII SLIDE-OUT

PA1553

13

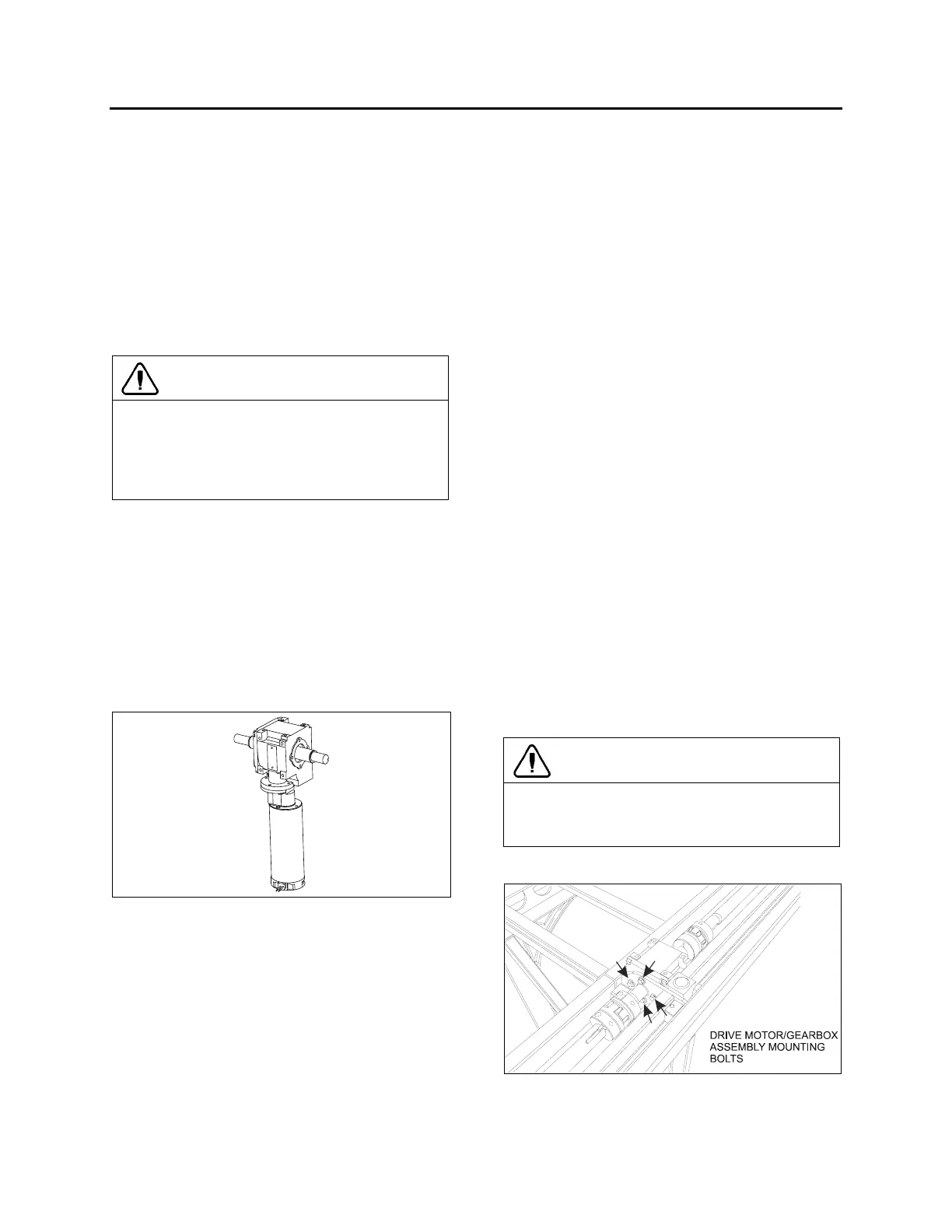

6 ELECTRIC MOTOR

The power is supplied by a 24V 1/3 HP electric

motor coupled with a speed reduction gearbox.

Opposite to the gearbox, the motor is equipped

with a 3/8 hexagonal socket shaft extension

permitting to move the slide-out without using

the handheld control. This is very useful when

moving the slide-out very slowly is required like

during the inner stoppers adjustment, the tilt

adjustment or the 2" inside retraction. See

section 18 for the manual override procedures.

CAUTION

When moving the slide-out with a cordless

power drill as described in the manual

override procedure, be careful as the slide-out

approaches its opened or closed position, in

order not to overload the mechanism.

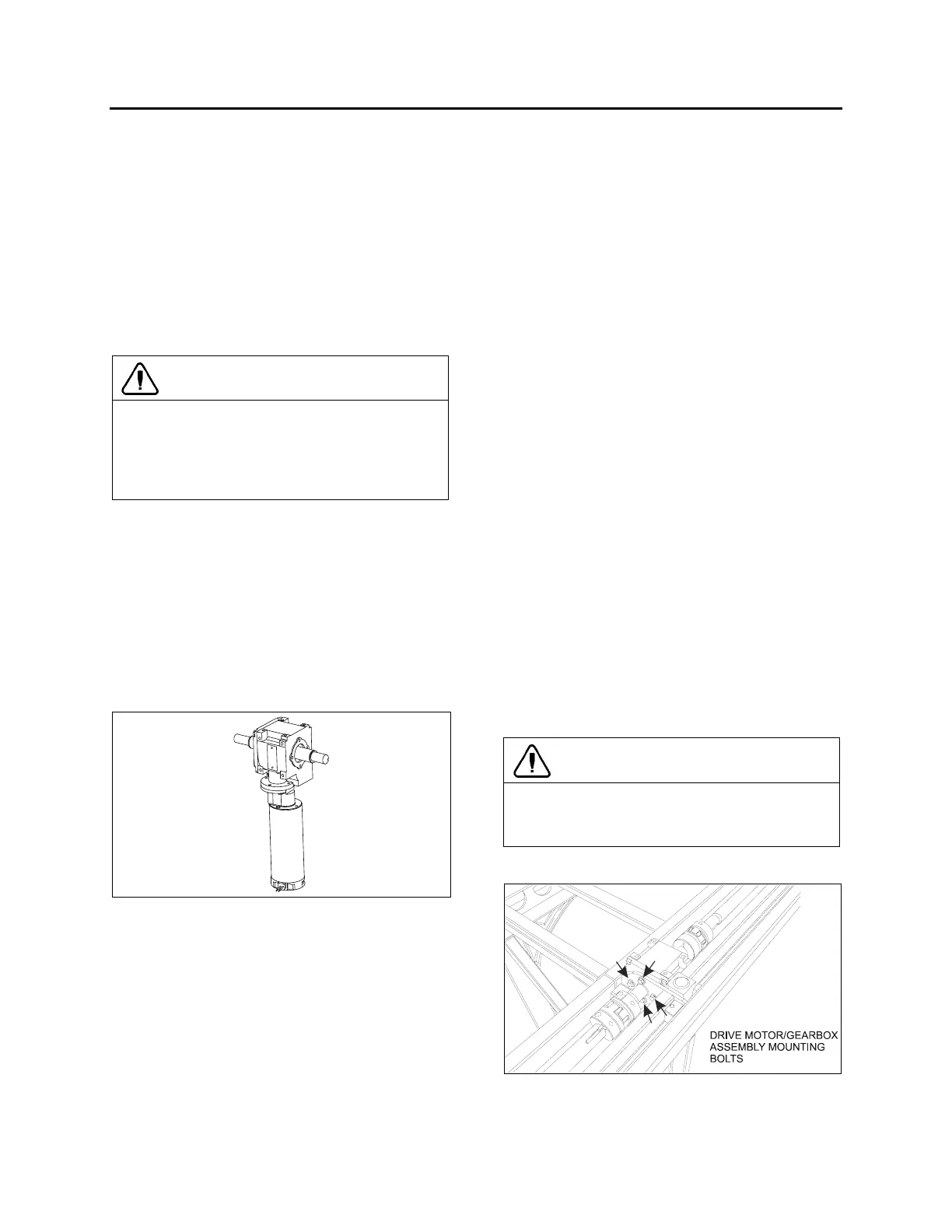

6.1 MAINTENANCE

Inspect the electrical connections and their

watertightness. Check that the mounting bolts

are tight (FIGURE 18).

6.2 REPLACEMENT

1. The slide-out must be retracted.

2. Unplug the electric cable connector.

FIGURE 17: ELECTRIC MOTOR AND SPEED REDUCTION

GEARBOX

3. Remove the motor from the gearbox.

4. Fasten the new motor to the gearbox using

screws.

5. Re-connect the electric cable connector.

7 SPEED REDUCTION

GEARBOX

The speed reduction gearbox used is a helical

worm gear type. This gearbox has a 2-stage

740:1 ratio and the output shafts are self-locking.

Keys on output shafts are glued into keyseats.

7.1 MAINTENANCE

Inspect the gearbox to check if there is any

leakage or backlash in the box. Replace the

gearbox if excessive wear is present. Check that

all bolts are tight.

The gearbox is lubricated for life and the oil

should not have to be changed.

7.2 GEARBOX REPLACEMENT

1. The slide-out must be retracted.

2. Disengage the shafts jaw couplings (refer to

section 8: JAW COUPLING).

3. Remove the 4 cap screws securing the drive

motor/gearbox assembly and dismount the

assembly (see FIGURE 18).

4. Remove the gearbox from the motor and

install the new one.

5. Reinstall the drive motor/gearbox assembly

on the vehicle mounting bracket. Tighten

mounting bolts to a torque of 18 lbf-ft in a

criss-cross patern.

CAUTION

To prevent damaging threads, use your

fingers to drive the bolts into the aluminum

gearbox housing mounting holes.

6. Reinstall the jaw couplings.

FIGURE 18: DRIVE MOTOR/GEARBOX ASSEMBLY

MOUNTING BOLTS

Loading...

Loading...