Section 13: WHEELS, HUBS & TIRES

PA1553

6

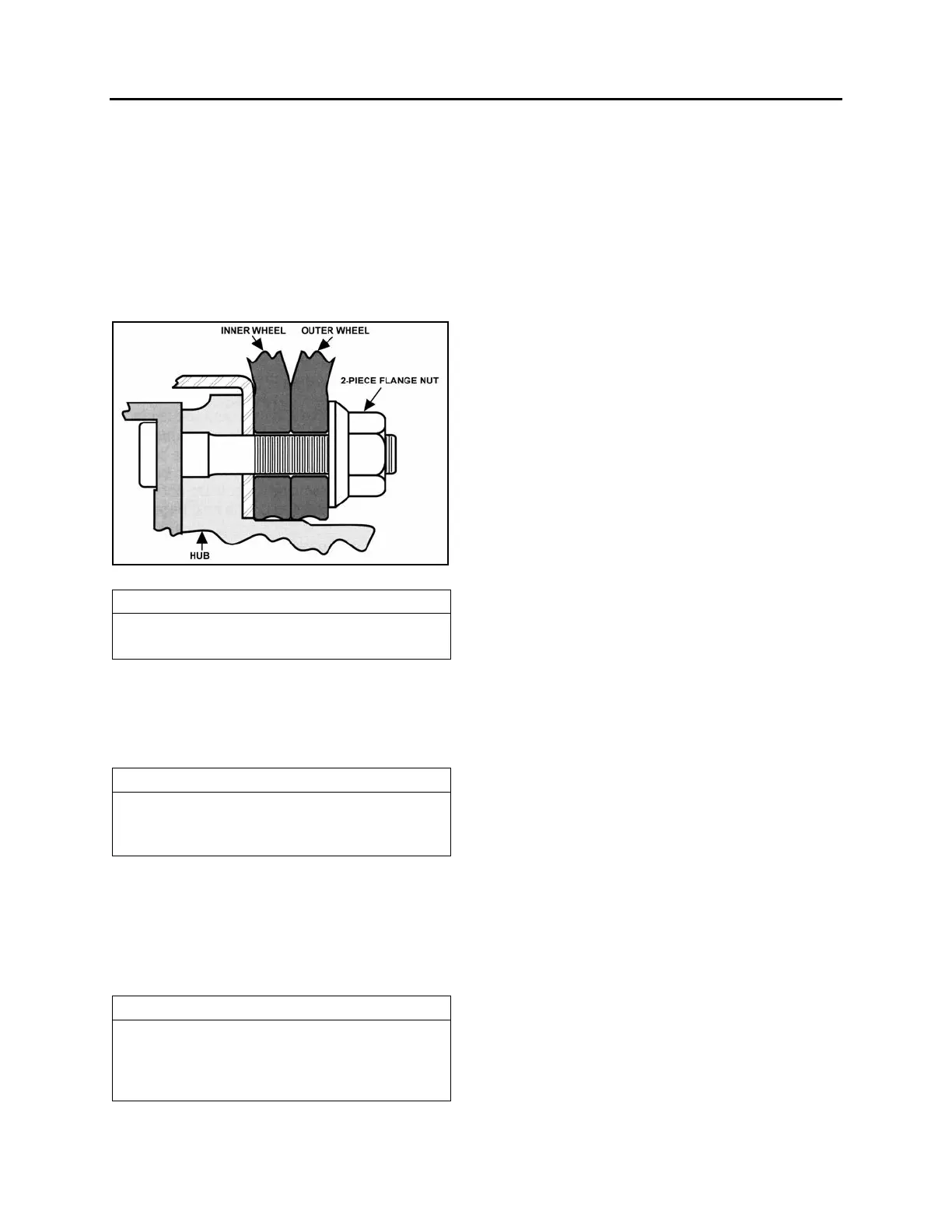

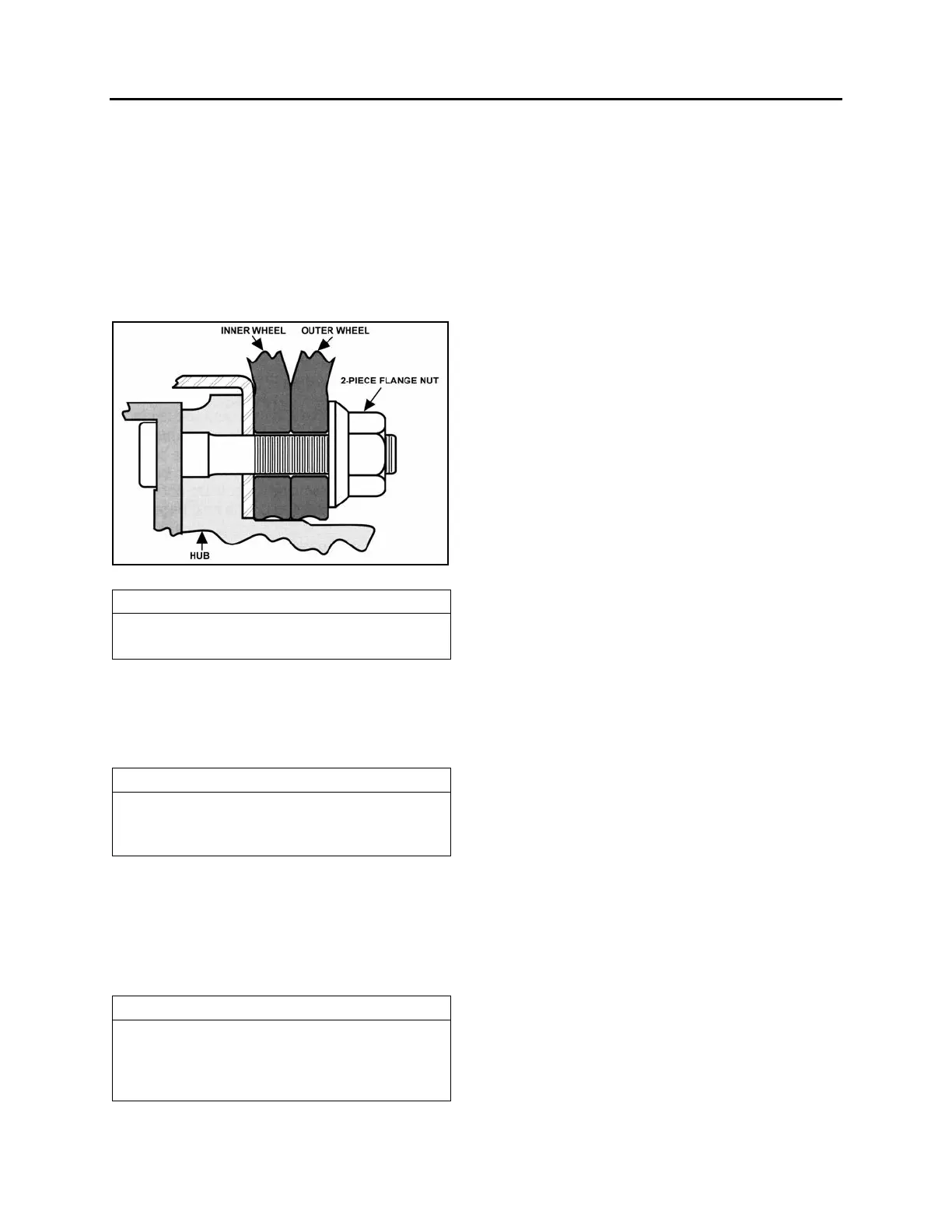

7. HUB MOUNTED WHEELS

Wheel surfaces in contact with hubs, nuts or

other wheels should be kept free of all rust,

grease and paint (except for initial “E” coat

protection, applied to stop rusting and to

facilitate wheel removal). The reason for this is

to assure that all faces are clamped together

without buildup of any coating. The threads of

the wheel studs and the wheel nuts should be

clean and undamaged.

FIGURE 5: HUB-MOUNTED WHEELS 13025

NOTE

When painting wheels, make sure to mask all

surfaces identified above.

Using a calibrated torque wrench, tighten wheel

nuts to 450 - 500 lbf-ft (610 - 680 Nm) of torque.

Do not use power tools or long bars for

tightening. Tighten wheel nuts alternately as

shown in figure 2.

NOTE

Tightening should not be done immediately

after prolonged braking or when wheel ends

are hot.

Check wheel nut torque at every 100 miles (160

km) for 500 miles (800 km) after fitting wheels.

Let cool before checking. If any relaxation of the

initial 450 - 500 lbf-ft (610 - 680 Nm) of torque

has occurred, retighten. Relaxation of initial

torque may occur because of the “bedding

down” of the hub and wheel surfaces.

NOTE

Torque relaxation occurs when wheel ends

are hot but should revert to original setting

when cool. Retightening when hot will produce

a higher torque reading than recommended.

7.1 CARE OF WHEELS

Check for cracks in wheels, especially around

the fixing holes, studs, nuts and washers. If in

doubt, renew.

Do not simply retighten very loose wheel fixings

or wheels that are continually becoming loose.

Find out why they are loose and whether any

damage has been caused.

Use trained personnel and keep records of all

attention to wheels and fixings, including which

parts were renewed and when.

8. FRONT AND TAG AXLE WHEEL HUBS

The unitized hub bearings used on the NDS

range of axles, are non-serviceable items.

Bearings are pre-adjusted, lubricated and have

seals fitted as part of the manufacturing process.

The bearings are greased for life and there is no

need or facility for re-lubrication

8.1 HUB BEARING INSPECTION

An inspection should be made at intervals of

30,000 miles (48 000 km).

o Apply parking brake, raise wheels off the

ground and support axle on stands. When

the wheels are raised, they should revolve

quite freely without roughness.

o Place magnetic base of a dial indicator on

brake caliper and position dial indicator stem

against a convenient marked spot on face of

hub flange.

o With dial indicator in position pull hard but

steadily on hub flange and oscillate at same

time until a steady reading is achieved.

o Without releasing the pressure, turn bearing

so that dial indicator stem contacts marked

spot and note reading on indicator.

o Push bearing flange hard and oscillate as

before until a steady reading is achieved.

o Without releasing the pressure, turn bearing

so that indicator stem again contacts the

marked spot and note new reading on

indicator.

o The difference between readings is the

amount of mounted end play in bearing unit.

o The mounted end play figure should not

exceed 0.050 mm for a new bearing.

Loading...

Loading...