Section 6: ELECTRICAL

PA1553

49

readings with published specifications in

Delco-Remy Service Bulletin 1G-186,

1G-187, or 1G-188. An alternator is

defective if it does not produce rated output

or if field windings are faulty. If the alternator

provides rated output, and field windings

check satisfactorily, the regulator should be

checked as covered under "Regulator

Checks".

8.1.2 Overcharged Battery

If the voltage setting as checked above is steady

and reasonably close to the specified value,

lower the setting by 0.3 volt and check for an

improved battery condition over a minimum

service period of 48 hours. If the voltage cannot

be adjusted to the desired value, proceed as

follows: where the alternator field is grounded

internally in the alternator as shown in figure 30

a shorted or grounded field or a defective

regulator can cause an overcharged battery.

The field winding can be checked as covered in

paragraph “Undercharged Battery”. If the field

winding is found to be correct, the alternator is

not defective, and the regulator should be

checked as covered under “Regulator Checks”.

8.2 REGULATOR CHECKS

Separate the cover from the base, and remove

the panel assembly from the cover. Carefully

note the location of all washers and lock

washers.

The component parts are keyed to figure 33.

Before making electrical checks, visually inspect

the components and make sure all soldered

connections are secure. Various electrical

checks with an ohmmeter can be made to

determine which components are defective.

The ohmmeter must be accurate, and should be

a scale-type meter with a 1.5 or 3 volt cell. Most

digital ohmmeters cannot be used to check

semiconductors. However, some digital

ohmmeters are specially designed to test

semiconductors and can be used to test

components in the regulator. Consult the

ohmmeter’s manufacturer for specifications

concerning the capabilities of the ohmmeter.

It is important that all of the following checks be

made. If a defective part is found, replace it

before proceeding with the remaining checks.

Be sure to make all the checks since more than

one component may be defective.

A defective regulator can be repaired according

to the following methods:

A) By changing the printed circuit board in the

regulator. Unscrew the retaining screws on

the printed circuit and remove it. Install a

new printed circuit board. This method is the

most commonly used.

B) By removing any retaining screws involved

and unsoldering the connections. When

resoldering, limit solder time to a minimum

as excessive heat may damage the printed

circuit board and component parts. However

good soldered connections are essential for

satisfactory operation. A resin core 63% tin

37% lead solder with a 360

o

F (182

o

C)

melting point is recommended along with a

soldering iron rated at 50 watts or less. Use

extreme care to avoid overheating. Before

checking the printed circuit board, remove

transistor TR1, which must be checked

separately. Connect the ohmmeter as

shown in figure 37, and then reverse the

ohmmeter leads to obtain two readings on

the same component. Use the middle scale

on scale-type meters on which the 300 ohm

value should be within or nearly within, the

middle third of scale.

Capacitors C1 and C2 = The ohmmeter should

read high and low on each capacitor. If not,

replace capacitor.

Diodes D1, D2 and D3 = Each diode should

give one high and one low reading. If not,

replace diode.

Resistor R2 = Turn voltage adjustment screw

(identified in figure 35) with ohmmeter

connecting each way. Reading should change

as slotted screw is turned. If not, replace R2.

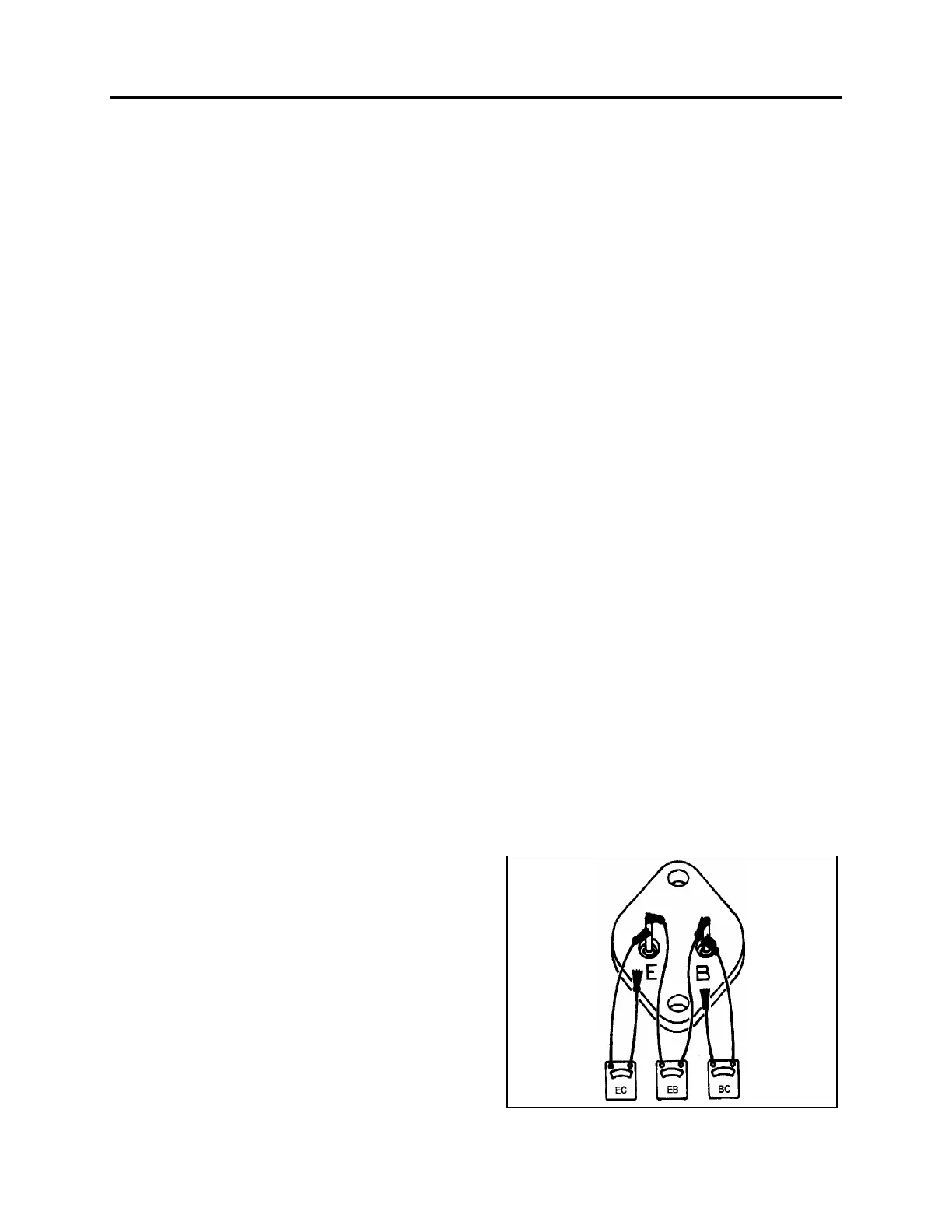

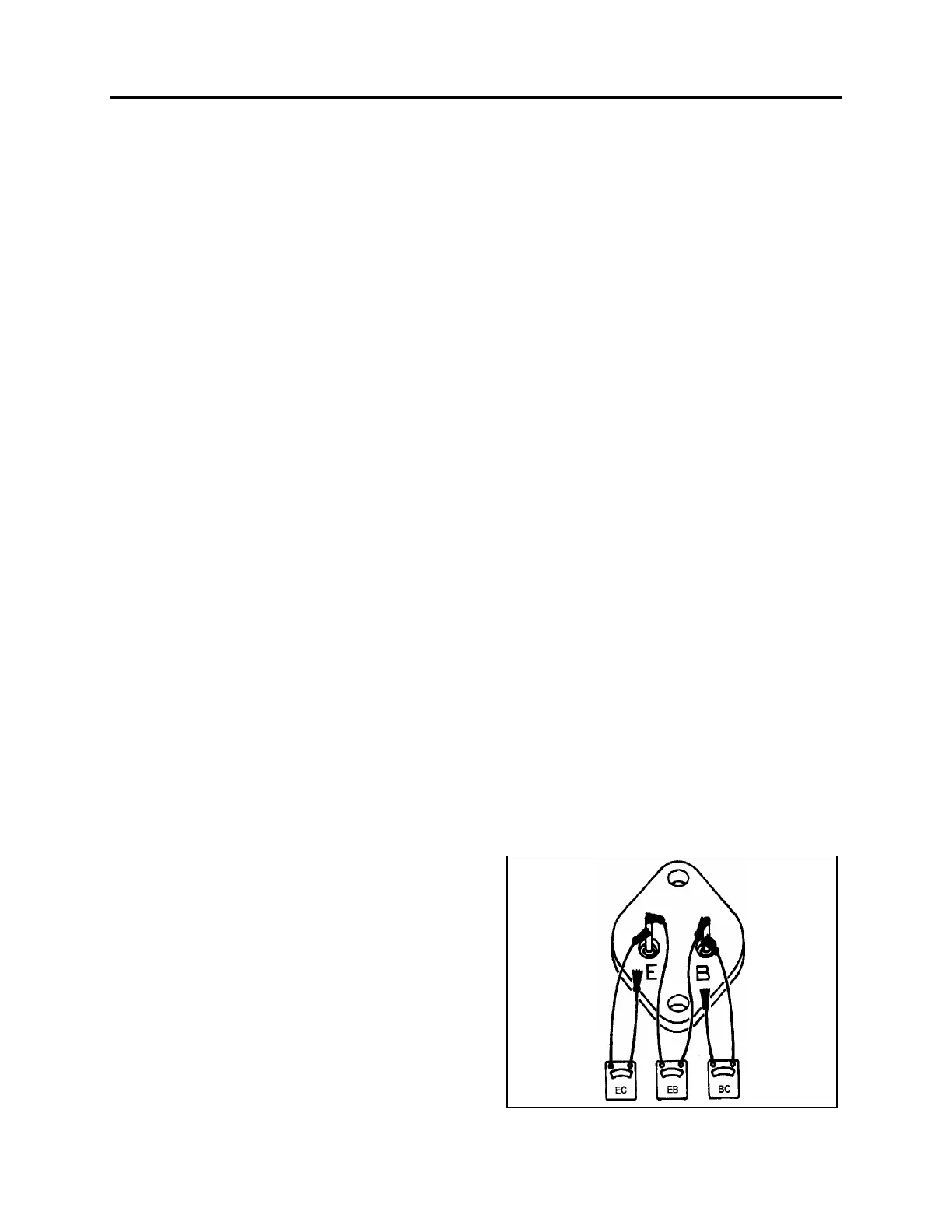

Transistor TR1 = See figure 37. Use the low

scale. Each of the three checks should read low

and high. If not, replace TR1.

FIGURE 37: CHECKING TRANSISTOR TR1 06081

Loading...

Loading...