Section 26: XLII SLIDE-OUT

PA1553

9

5 PINION

CAUTION

Make sure all keyless bushings are tightened

to 125 lb-ft before moving the slide-out. Refer

to section 5.4 for torque wrench settings. A

lower torque value may cause the bushing to

slip on the shaft, and a higher torque value

may break the bushing.

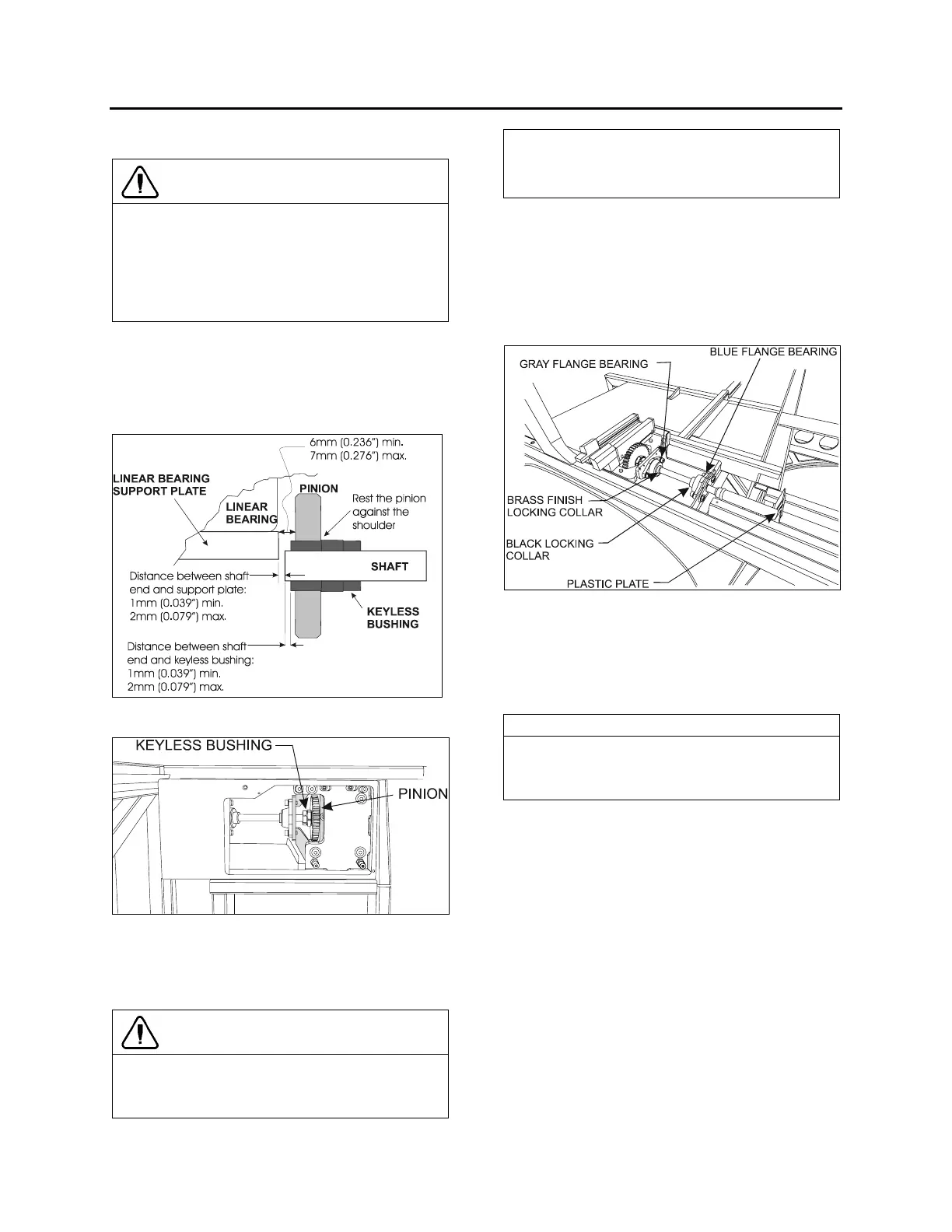

5.1 PINION AND KEYLESS

BUSHING POSITIONING

For proper functioning, respect the positioning

shown on the following figure.

FIGURE 11: PINION AND KEYLESS BUSHING

POSITIONING

FIGURE 12: PINION AND KEYLESS BUSHING AS SEEN

FROM EVAPORATOR COMPARTMENT

5.2 FRONT SLIDE-OUT SHAFT

PINION REPLACEMENT

CAUTION

Before reinstalling the pinion, clean the

following surfaces with alcohol to prevent

slippage.

o Pinion bore;

o Keyless bushing I.D. and O.D.;

o Shaft.

Before proceeding with the front slide-out shaft

pinion replacement, check the following

conditions:

- The locking collars located on the side of the

pinion being replaced are disengaged;

- The drive motor/gearbox assembly is

removed (see section 7.2);

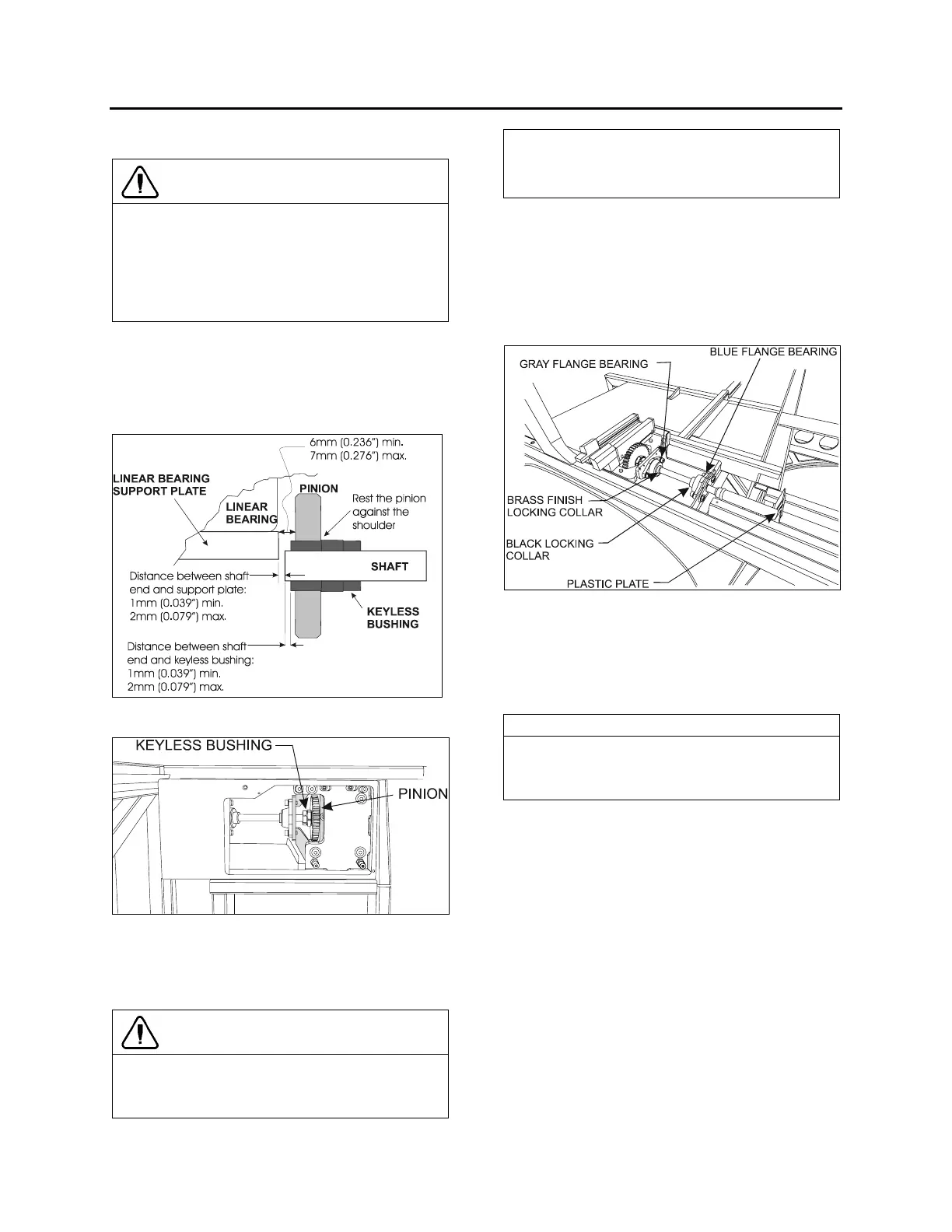

FIGURE 13: MECHANICAL COMPONENTS (TYPICAL)

1. Loosen the keyless bushing (see section

5.4) of the pinion to be replaced. Slide the

pinion and its bushing out of the shaft.

Check the keyless bushing condition and

replace if needed.

NOTE

If necessary, loosen the blue and gray flange

bearing to move the pinion away from the

rack.

2. Assemble new pinion on the keyless

bushing and then slide on the shaft. Do not

tighten the bushing at this moment.

3. Properly position the shaft end in relation to

the linear bearing support plate (see

FIGURE 11) and then tighten the locking

collars to maintain the shaft in that position.

4. Position pinion and keyless bushing as

shown on FIGURE 11 and tighten the

keyless bushing as described in section 5.4.

5. Reinstall the drive motor/gearbox assembly.

Loading...

Loading...