Rim flange

wear

2-11

To obtain a gauge(s) at no charge and information on free training on proper

installation and maintenance procedures, contact Alcoa Wheel and Forged

Products at (800) 242-9898 option 1 or on the web at www.alcoawheels.com.

STEP 1. Remove the wheel/tire assembly from the vehicle. Remove the valve core

to deflate the tire completely. Remove the tire from the wheel according to OSHA

regulations, TMC recommended practices for tire and rim safety procedures

and/or the Alcoa Wheel Service Manual.

Alcoa Rim Flange Wear Gauge Instructions

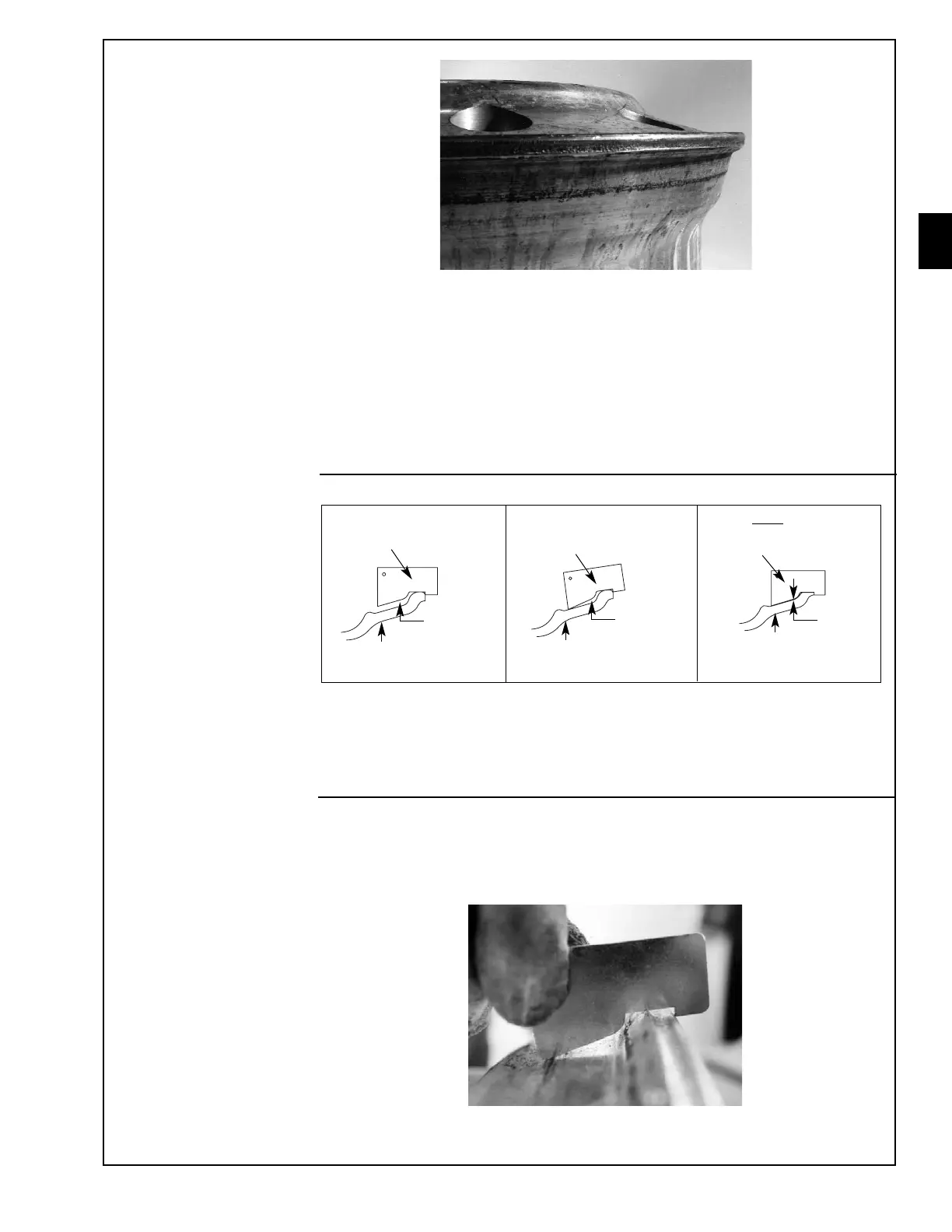

Determining Rim Flange Wear

Wheel rim

Wheel rim

Wheel rim

Rim Gauge

Alcoa P/N 000700

Rim Gauge

Alcoa P/N 000700

Rim Acceptable

Rim NOT

Acceptable

Rim Acceptable

Rim Gauge

Alcoa P/N 000700

Daylight in this

area indicates

acceptable rim.

No daylight

in this area

indicates

excessive

wear

Remove from service immediately.

Irregular wear on the surface of the rim flange is caused by abrasion from the

tire chafer and sidewall. Rim flange wear happens most often in applications

with heavy or shifting loads. If you are experiencing excessive rim flange wear

in your operation, consider using Alcoa Dura-Flange

®

aluminum wheels. These

wheels have been specially treated to significantly reduce rim flange wear.

Remove wheels from service when rim flange wear is excessive. Excessive

wear can be determined using an Alcoa approved wear gauge and procedures

detailed below. If rim flange wear becomes sharp and/or cuts the tire, contact

Alcoa for recommended maintenance procedures.

13

2

Photo 1. Acceptable Rim Flange Wear Condition

Daylight in this

area indicates

acceptable rim.

Loading...

Loading...