SECTION 01: ENGINE

PA1553

5

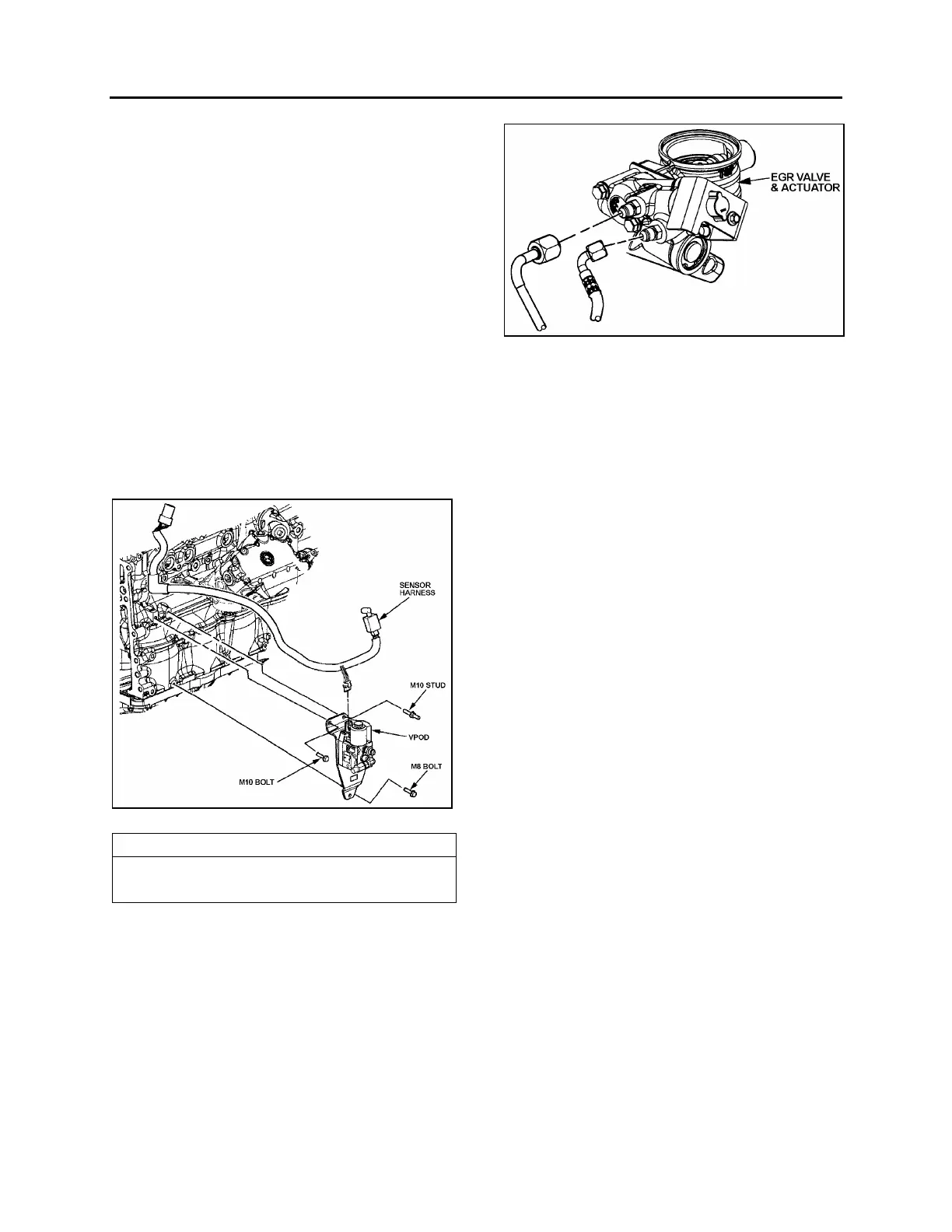

2.3.1 VPOD Removal

1. Remove airline from VPOD.

2. Unplug harness connection.

3. Remove two bolts and one stud holding

VPOD assembly and bracket to engine

block.

2.3.2 VPOD Installation

1. Align VPOD assembly and bracket to

threaded holes in engine block; install two

bolts and one stud. Torque the M10 bolts

and M10 stud to 43-54 Lbf-ft (58-73 Nm).

Torque the M8 bolt to 22-28 Lbf-ft (30-38

Nm).

2. Connect airline to VPOD and tighten.

3. Plug harness connection into VPOD

assembly.

FIGURE 5: VPOD INSTALLATION 01147

NOTE

VPOD assembly is not serviceable, remove

and replace only.

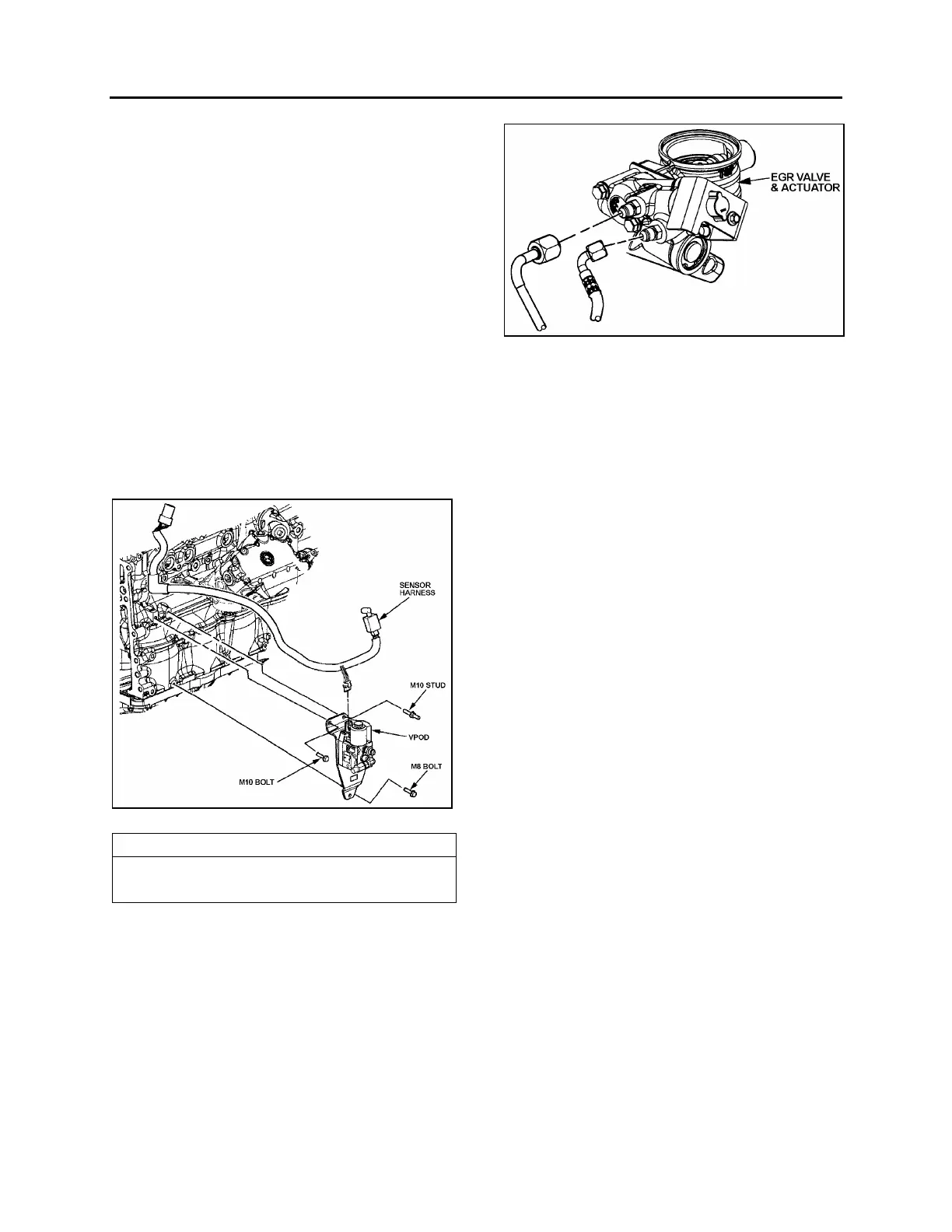

2.4 EGR HYDRAULIC VALVE

The hydraulic valve that controls the Exhaust

Gas Recirculation (EGR) system is located on

the same side as the VPOD but near the EGR

cooler (Fig. 1 & 6).

FIGURE 6: EGR VALVE & ACTUATOR ASSEMBLY 01148

2.5 SYNCHRONOUS REFERENCE SENSOR

The Synchronous Reference Sensor (SRS) is

an electronic component, mounted to the rear of

the gear case (Fig. 1). The SRS senses a raised

metal pin on the rear of the camshaft idler gear

and sends a signal to the ECM via a black

connector wire. The SRS sensor extends

through a hole in the gear case. It is positioned

near the rear of the idler gear. A bolt, inserted

through a hole in the SRS bracket, secures the

SRS assembly to the gear case.

The idler gear pin passes by the SRS as piston

number one crank pin reaches 45° before Top-

Dead-Center. The ECM uses this information to

determine engine speed.

The SRS is non-serviceable and must be

replaced as a unit. No adjustment is required.

2.6 TIMING REFERENCE SENSOR

The Timing Reference Sensor (TRS) is an

electronic component mounted on the left side

of the gear case (right side of coach), near the

crankshaft centerline. The TRS is positioned

near the timing wheel gear teeth and extends

through an opening in the gear case. A bolt,

inserted through a hole in the TRS bracket,

secures the TRS assembly to the gear case.

The TRS connector is gray. The TRS sends a

signal to the ECM, this signal is generated by a

series of evenly spaced special teeth on the

timing wheel. A tooth passes by the TRS as

each cylinder crank pin reaches 10° before Top-

Dead-Center.

The ECM uses these signals to determine

injector solenoid operation time. The TRS is

non-serviceable and must be replaced as a unit.

No adjustment is required.

Loading...

Loading...