5

36

Owner/in-service

identification

5-5

Some fleets wish to specially identify wheels as to OWNERSHIP and IN-SERVICE dates.

Alcoa recommends that fleets and owner-operators adopt the practice of permanently

stamping wheels with the date they are first placed into service.

1. Use “Lo-Stress” stamps or equivalent.

2. Location of stamped areas on outside disc should be in space outward from a line

between hand hole centers and a minimum of one inch from the periphery of any hand hole.

3. Location of stamped identification on inside of wheel should be as close to the factory

identification stamping as possible.

Note: Use of an impression stamp on Dura-Bright

®

surface treated wheels can affect

the appearance and performance of the Dura-Bright

®

surface treatment local to the stamp.

Valves

5-6

Alcoa drop center wheels for tubeless tires come from the factory with air valves

installed. If it becomes necessary to replace an air valve, install it using the following

torque values.

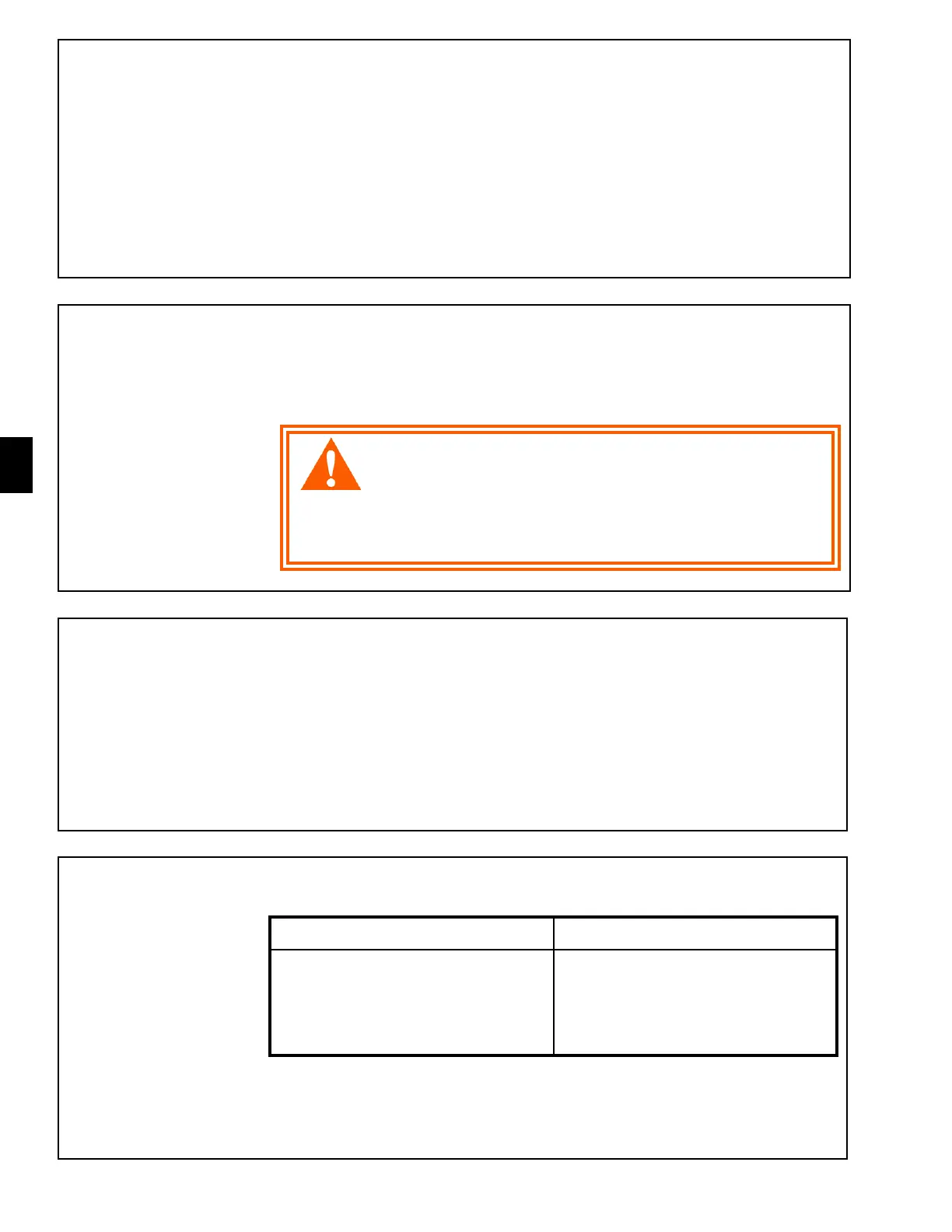

10-14 foot-pounds for Part Nos. 7-11 foot-pounds for Part Nos.

TR 509 TR 542 Series

TR 510 TR 543 Series

TR 511 TR 544 Series

TR 545 Series

60MS27N

Replacement valves may be obtained from your authorized Alcoa Wheel Distributor.

Always use silicone o-rings – not rubber – when reinstalling valve stems. Metal valve

stem caps are recommended instead of plastic.

When replacing valve stems, it is recommended to lubricate the threads and o-ring

with a non-waterbased lubricant.

Do not straighten

wheels

5-4

Do not heat wheels in an attempt to soften them for straightening to repair damage

from striking curbs or other causes. The special alloy used in these wheels is heat

treated, and uncontrolled heating will weaken the wheel.

Do not rework, weld, heat or braze Alcoa aluminum wheels for any reason. This does

not include normal wheel maintenance as described and approved by Alcoa.

Lead balance

weights (clip on)

5-3

Lead balance weights for Alcoa wheels are available from your Alcoa Wheel Distributor.

With radial tires it may be necessary to temporarily reduce the tire pressure when

installing clip-on weights to allow clearance of the weight clamp over the rim flange.

Use of coated balance weights is recommended to avoid staining and corrosion

of the aluminum wheel surface.

Excessive rim flange wear (see section 2-11, pages 13-17) could dictate the use of

“stick-on” or adhesive wheel weights if there is inadequate rim to properly hold a clip-on

style weight.

Improperly installed weights could “fly off” during use and damage the vehicle or cause

personal injury. Always follow the recommended procedures in this manual or the wheel

weight manufacturer. Adhesive weights should be applied only to a clean surface

on the brake side of the wheel rim. These weights should be installed only in a location

where they will not contact the brake components during vehicle operation.

WARNING Welding or brazing the rim flange or any area of an Alcoa aluminum wheel will

weaken the wheel. Weakened or damaged wheels can lead to an explosive separation

of tires and wheels or wheel failure on the vehicle.

Explosive separations of tires and wheels or wheel failure on the vehicle could cause

injuries or death.

Never attempt to weld or braze any surface of an Alcoa aluminum wheel.

WARNING

Loading...

Loading...