Section 11: REAR AXLES

PA1553

3

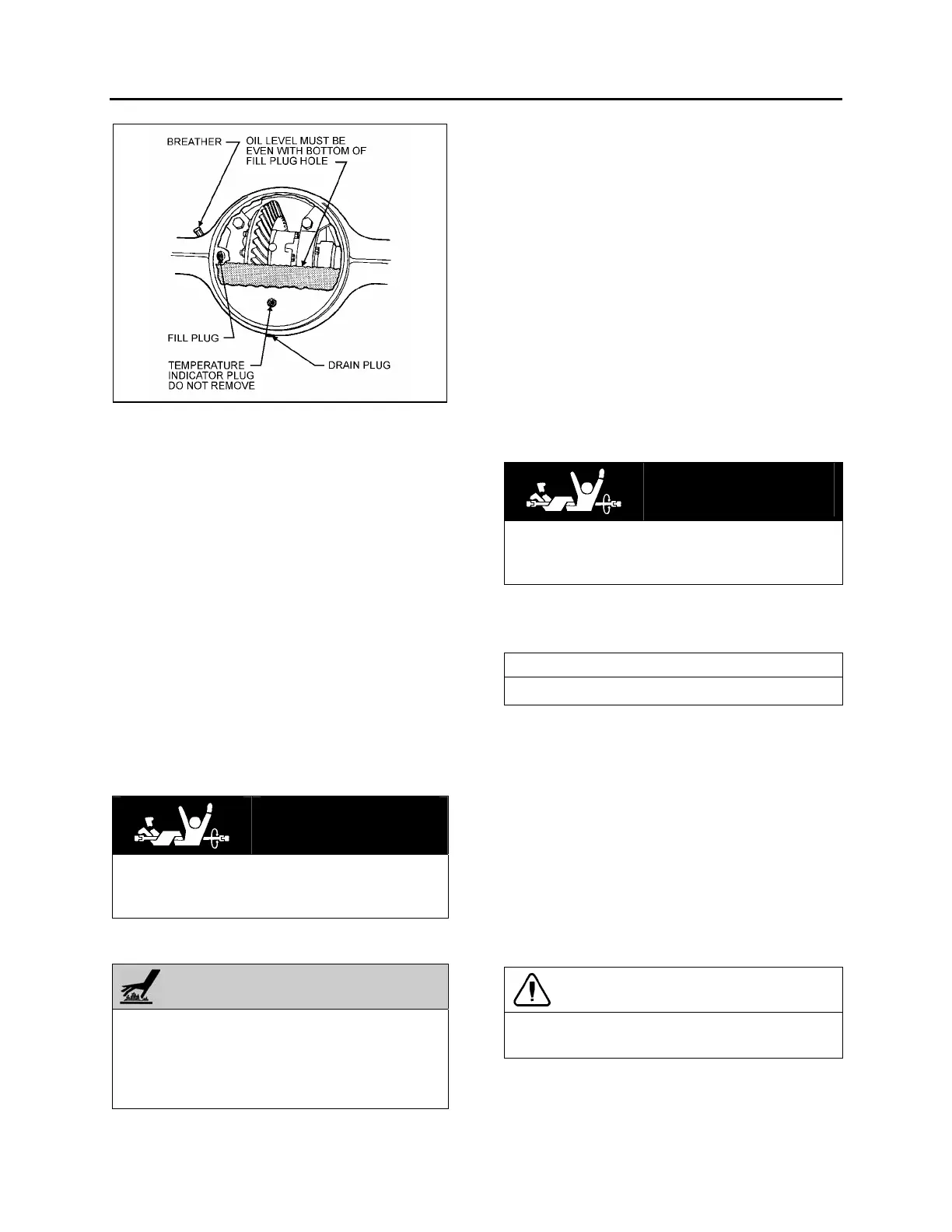

FIGURE 4: DIFFERENTIAL HOUSING BOWL 11007

1.4 MAINTENANCE

Proper vehicle operation begins with preventive

maintenance, such as good differential use. The

most common types of drive axle carrier failures

are spinout, shock, fatigue, overheating and

lubrication. Avoid neglecting these points since

they would be the first steps to improper

maintenance, expensive repairs, and excessive

downtime.

Inspect the pinion oil seal, axle shaft flange and

carrier housing gaskets for evidence of lubricant

leakage. Tighten the bolts and nuts, or replace

the gaskets and seals to correct leaks.

Maintenance of the axle mountings consists

primarily in a regular and systematic inspection of

the air suspension units and radius rods, as

directed in Section 16, "Suspension".

1.4.1 Checking and Adjusting the Oil Level

DANGER

Before servicing, park safely over a repair pit,

apply parking brake, stop engine and set

battery master switch to the "OFF" position.

1. Make sure the vehicle is parked on a level

surface.

WARNING

Check the oil level when the axle is at room

temperature. When hot, the oil temperature

may be 190ºF (88ºC) or more and can cause

burns. Also, a correct reading is not obtained

when the axle is warm or hot.

2. Make sure the axle is "cold" or at room

temperature.

3. Clean the area around the fill plug. Remove

the fill plug from the differential axle housing

bowl (Fig. 4).

4. The oil level must be even with the bottom of

the hole of the fill plug.

a. If oil flows from the hole when the plug is

loosened, the oil level is high. Drain the

oil to the correct level.

b. If the oil level is below the bottom of the

hole of the fill plug, add the specified oil.

5. Install and tighten the fill plug to 35-50 lbf-ft

(48-67 Nm).

1.4.2 Draining and Replacing the Oil

DANGER

Before servicing, park safely over a repair pit,

apply parking brake, stop engine and set

battery master switch to the "OFF" position.

1. Make sure the vehicle is parked on a level

surface. Put a large container under the

axle's drain plug.

NOTE

Drain the oil when the axle is warm.

2. Remove the drain plug from the bottom of the

axle. Drain and discard the oil in an

environment friendly manner.

3. Install and tighten the drain plug to 35-50

lbf-ft (48-67 Nm).

4. Clean the area around the fill plug. Remove

the fill plug from the differential housing bowl.

5. Add the specified oil until the oil level is even

with the bottom of the hole of the fill plug.

Allow the oil to flow through the axle and

check the oil level again (lube capacity 41

pints [13,3 liters]).

CAUTION

The differential overheats when the oil

temperature rises above 250ºF (120ºC).

6. Install and tighten the fill plug to 35-50 lbf-ft

(48-67 Nm).

Loading...

Loading...