Section 03: FUEL SYSTEM

PA1553

11

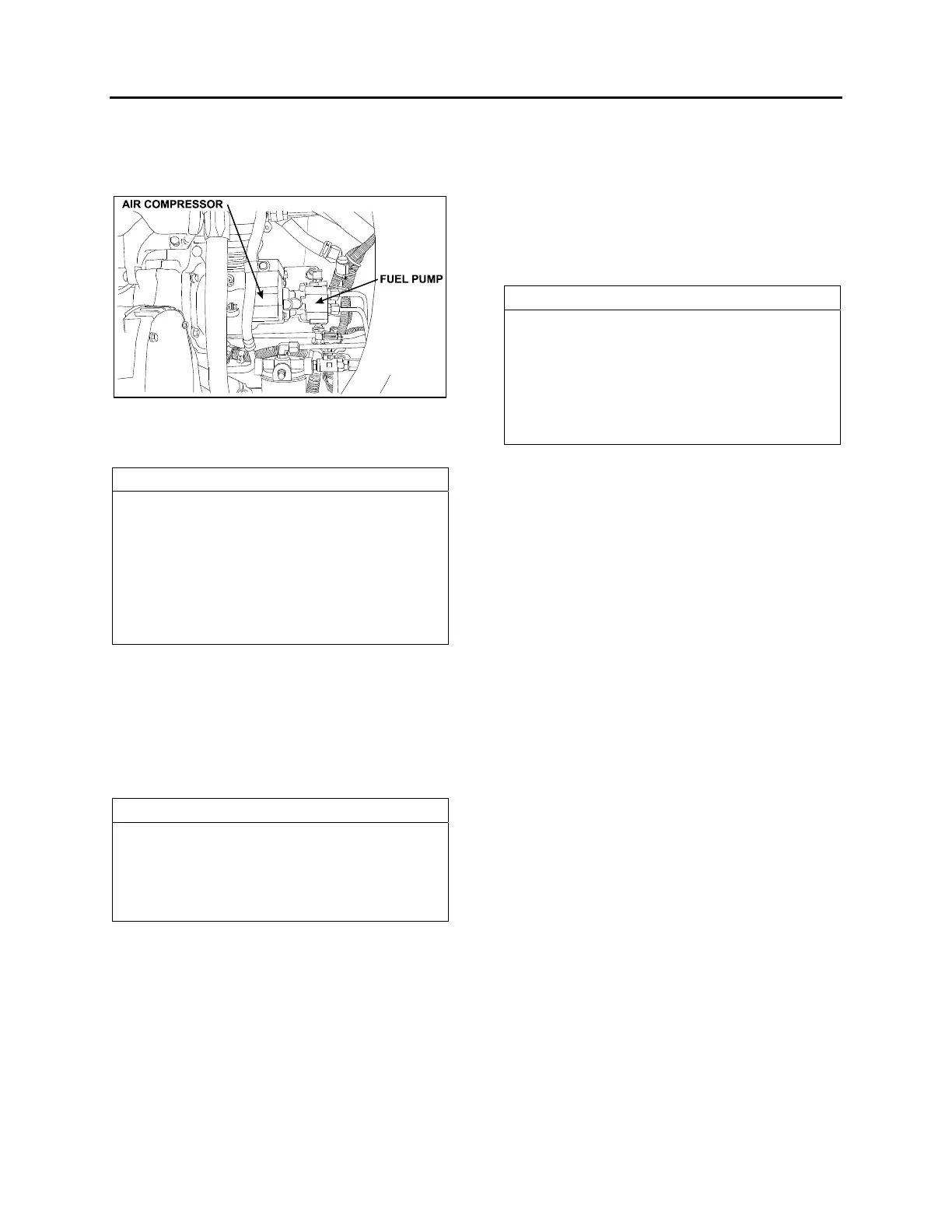

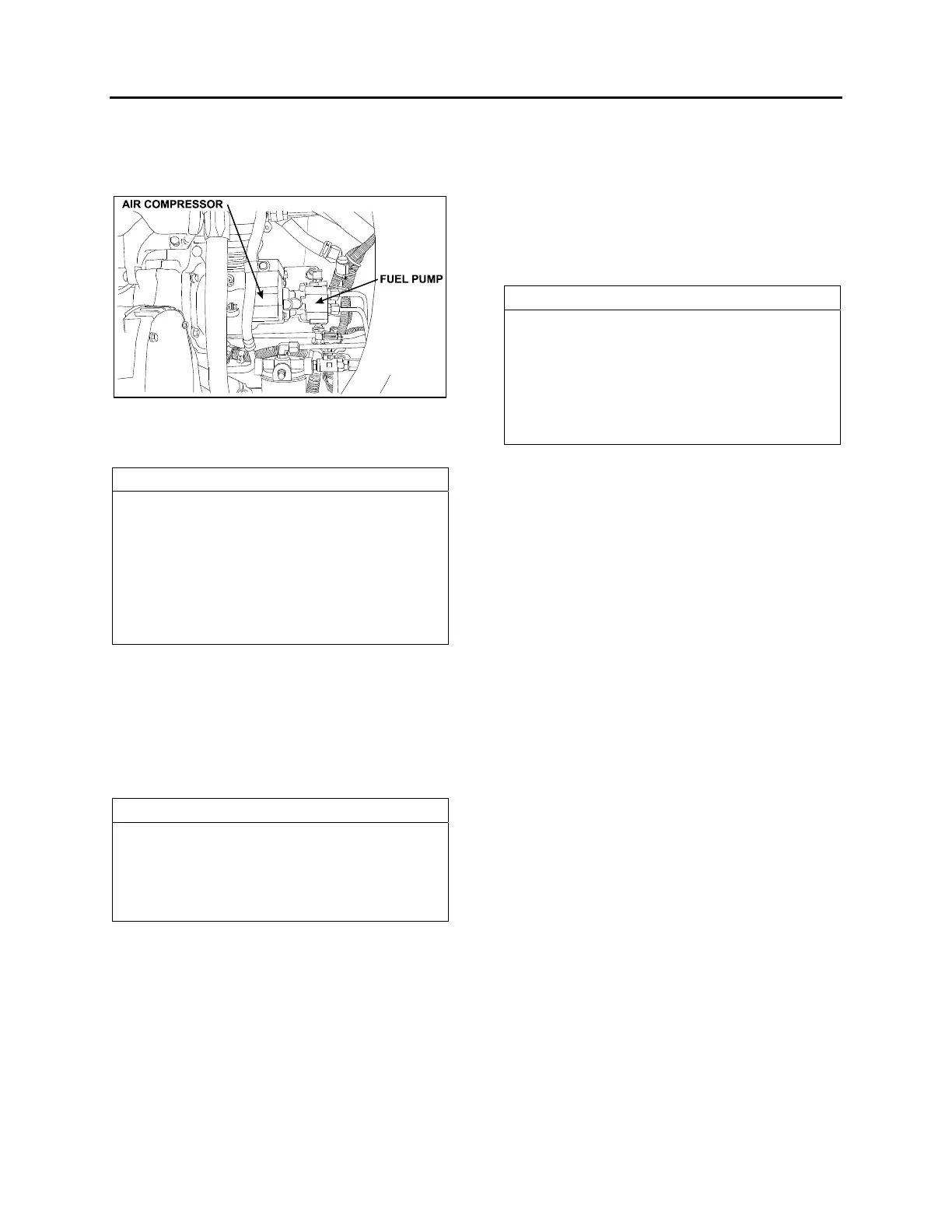

7. FUEL PUMP INSTALLATION

The fuel pump is driven off the rear of the air

compressor.

FIGURE 10: FUEL PUMP LOCATION

03053

1. If removed, install inlet and outlet fittings in

the cover of the fuel pump.

NOTE

New fittings have sealant already applied.

When reusing fittings, coat the threads lightly

with Locktite Pipe Sealant, Detroit Diesel

number J 26558-92, or equivalent, before

installing. To prevent sealant from entering

fuel system, do not apply to the first two

threads of the fitting. Do not use Teflon tape

or paste on the fittings.

2. Install drive coupling in drive hub of the fuel

pump. Install a new gasket to the mounting

flange of the pump.

3. Index the drive coupling with the drive hub on

the end of the air compressor crankshaft and

align the pump mounting bolt holes with

those in the air-compressor rear cover.

NOTE

When correctly positioned, the outlet fitting on

the pump should be in approximately an 8

o'clock position when viewed from the rear,

and the drain opening in the pump body

facing down.

4. Seat the fuel pump squarely against the air

compressor. Pilot the flange on the pump

body, in the opening in the rear cover of the

compressor. Install three mounting bolts and

tighten them to 22-28 Lbf-ft (30-38 Nm).

5. Connect the fuel inlet and outlet lines to the

fuel pump and tighten.

6. Prime engine fuel system before starting

engine to ensure pump seal lubrication and

prompt engine starting.

8. FUEL OIL SPECIFICATIONS

The quality of fuel oil used for high-speed diesel

engine operation is a very important factor in

obtaining satisfactory engine performance, long

engine life and acceptable exhaust emission

levels. The fuel oil should meet ASTM

designation D 975. Grade 1-D is recommended,

however grade 2-D is acceptable.

NOTE

These fuel grades are very similar to grade

DF-1 or DF-2 of Federal Specifications

VV-F-800. For detailed fuel

recommendations, refer to publication "Engine

Requirements-Lubricating Oil, Fuel, and

Filters" #7SE270 available from Detroit Diesel

Distributors.

9. AIR CLEANER (DRY TYPE)

The vehicle is equipped with a dry-type

replaceable element air cleaner, located in the

engine compartment. Access the air cleaner

through the engine R.H. side door. Engine air

enters the air cleaner through (2) two intake

ducts located just above engine side doors. It

then flows through a pre-cleaner and finally

through the air cleaner. The pre-cleaner

removes dust and moisture by means of a

discharge tube at the bottom of the element. It is

in series with a replaceable impregnated paper

filter element (air cleaner).

9.1 PRE-CLEANER SERVICING

The pre-cleaner is designed to be self-cleaning;

however, it should be inspected and any

accumulated foreign material removed during

the periodic replacement of the impregnated

paper filter element.

9.2 AIR CLEANER SERVICING

Stop the engine, open the R.H. side engine

compartment door, and loosen the wing nut

retaining the air cleaner element to the air

cleaner. Remove the element by pulling on the

handle in the center of the air cleaner element.

Install cleaner element as follows:

1. Inspect the gasket-sealing surface inside the

air cleaner. It must be smooth, flat and clean;

2. Install the air cleaner element;

3. Make sure that the element seals securely;

Loading...

Loading...