Section 05: COOLING SYSTEM

PA1553

5

NOTE

In order to ensure the integrity of the system,

it is recommended that a periodic cooling

system pressure check be made. Pressurize

the cooling system to 103-138 kPa (15-20 psi)

using Radiator and Cooling System Tester,

J24460-1. Do not exceed 138 kPa (20 psi).

Any measurable drop in pressure may

indicate a leak. Whenever the oil pan is

removed, the cooling system should be

pressure checked as a means of identifying

any incipient coolant leaks. Make sure the

cause of the internal leak has been corrected

before flushing the contaminated system.

Leaks at the thermostat housing hose

connections may be caused by deformation of

connections or by rough surfaces on the castings

of the hose mounting surfaces. It is

recommended that "Dow Corning RTV-102

Compound" or any equivalent product be applied

on cast surfaces prior to hose installation.

CAUTION

Castings should be clean and free of oil and

grease before applying compound. No other

sealer should be used with RTV-102

compound.

3. HOSES

Rotten, swollen, and worn out hoses or loose

connections are frequent causes of cooling

system problems.

Serious overheating is often caused by an old

hose collapsing or from rotten rubber shedding

from hoses and clogging the coolant passages.

Connections should be inspected periodically

and hose clamps tightened. Replace any hose

found to be cracked or swollen.

When installing a new hose, clean pipe

connections and apply a thin layer of a

non-hardening sealing compound. Replace worn

out clamps or clamps that pinch hoses.

3.1 CONSTANT-TORQUE HOSE CLAMPS

All hose clamps of 1 3/8" ID and over, used on

the heating and cooling systems, are of the

"Constant-torque" type. These clamps are

worm-driven, made of stainless steel, and

supplied with a series of Belleville spring

washers. They also feature an extended integral

liner that covers the band slots to protect

soft/silicone hoses from damage, and help

maintain consistent sealing pressure.

This type of clamp is designed to automatically

adjust its diameter to compensate for the normal

expansion/contraction of a hose and metal

connection that occurs during vehicle operation

and shutdown. The constant-torque clamp

virtually eliminates coolant losses due to "Cold

flow" leakage and greatly minimizes clamp

maintenance.

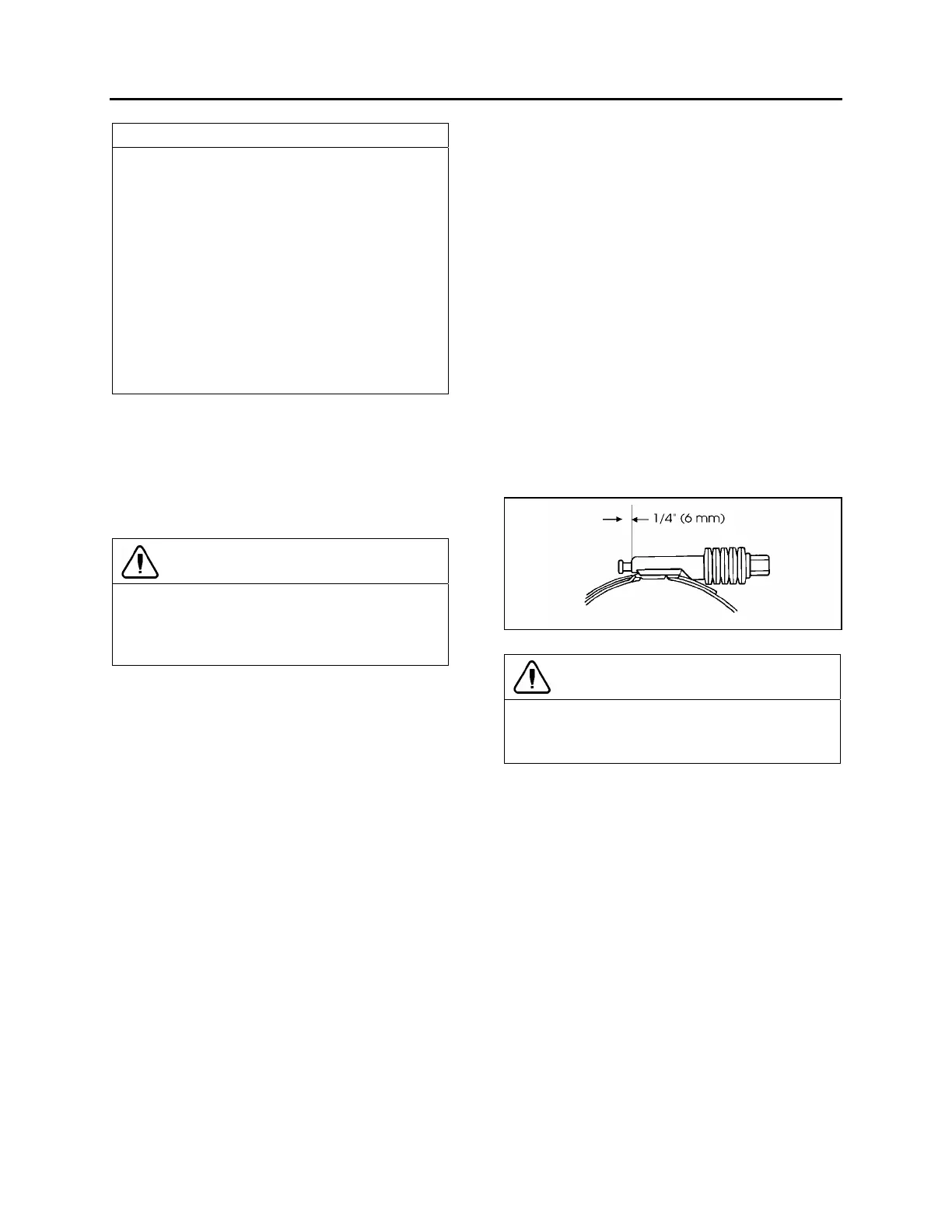

3.1.1 Installation

A torque wrench should be used for proper

installation. The recommended torque is 90 to

100 lbf-in. (10 to 11 Nm). The Belleville spring

washer stacks should be nearly collapsed flat

and the screw tip should extend ¼" (6 mm)

beyond the housing (Fig. 3).

FIGURE 3: CONSTANT-TORQUE CLAMP 05037

CAUTION

The hose clamps will break if over-torqued.

Do not over-tighten, especially during cold

weather when hose has contracted.

3.1.2 Maintenance

The constant-torque clamps contain a "Visual

torque check“ feature. When the tip of the screw

is extending ¼" (6 mm) out of the housing, the

clamp is properly installed and maintains a

leak-proof connection. Since the constant-torque

clamp automatically adjusts to keep a consistent

sealing pressure, there is no need to re-torque

hose clamps on a regular basis. During vehicle

operation and shutdown, the screw tip will adjust

according to the temperature and pressure

changes. Checking for proper torque should

be done at room temperature.

Loading...

Loading...