Section 06: ELECTRICAL

PA1553

18

3.5.1 Visual Inspection

1. Check the outside of the battery for a broken

or cracked cover or case that could permit

loss of electrolyte. If obvious physical

damage is noted, replace the battery.

2. Check for loose terminal posts, cable

connections, damaged cables, and for

evidence of corrosion. Correct conditions as

required before proceeding with tests.

3.5.2 Removing Surface Charge

Disconnect cables from the battery and attach

alligator clamps to the contact lead pad on the

battery as shown in figure 17. Connect a 300

ampere load across the terminal for 15 seconds

to remove surface charge from the battery.

3.5.3 Load Test

This test is one means of checking the battery to

determine its ability to function as required in the

vehicle.

To make this test, use test equipment that will

withstand a heavy electrical load from the

battery, such as a carbon pile resistor or other

suitable means.

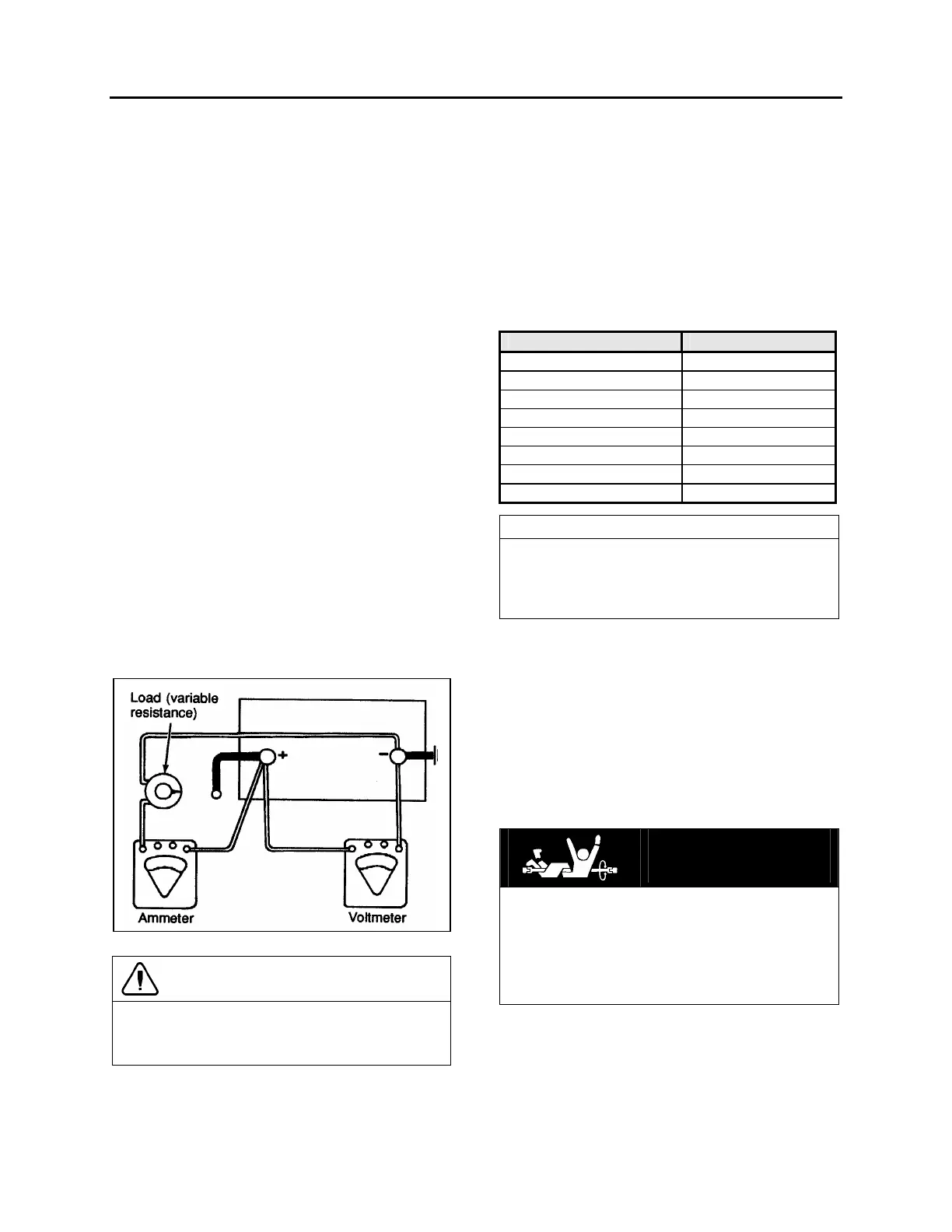

1. Connect a voltmeter, ammeter, and a

variable load resistance as illustrated in

figure 16.

FIGURE 16: LOAD TEST 06064

CAUTION

Observe polarity of the meters and the battery

when making connections, and select the

correct meter range.

2. Apply a 290 amperes load to the battery for

15 seconds.

3. With an ammeter reading specified load,

read voltage. The voltage should be at least

9.6 volts. Disconnect the load. If the

voltmeter indicates 9.6 volts or more, the

battery is good. If the voltmeter reading is

less than 9.6 volts, replace the battery. This

voltage is to be used for battery ambient

temperatures of 70ºF (21ºC) and above. For

temperatures below 70ºF (21ºC), refer to the

following "Voltage and Temperature Chart".

Voltage and Temperature Chart

Ambient Temperature Minimum Voltage

70ºF (21ºC) and above 9.6

60ºF (16ºC) 9.5

50ºF (10ºC) 9.4

40ºF (4ºC) 9.3

30ºF (-1ºC) 9.1

20ºF (-7ºC) 8.9

10ºF (-12ºC) 8.7

0ºF (-18ºC) 8.5

NOTE

The accuracy of this test procedure is

dependent upon close adherence to the

proper load, time and temperature

specifications.

3.5.4 Testing Battery Cables

Check all cable ring terminals and connections to

determine if they are in good condition.

Excessive resistance, generally caused by poor

connections, produces an abnormal voltage drop

which may lower voltage at the starter to such a

low value that normal operation of the starter will

not be obtained. An abnormal voltage drop can

be detected with a low-reading voltmeter as

follows:

DANGER

To prevent the engine from starting, the DDEC

engine circuits, which are protected by

breakers (CB-1 & CB-2) located in the circuit

breaker panel, must be deenergized during

these tests; afterward toggle yellow lever

upwards to reset the circuit breakers.

1. Check voltage drop between grounded

(negative) battery terminal and vehicle frame

by placing one prod of the voltmeter on the

battery terminal and the other on a good

ground (unpainted surface) on the vehicle.

With the starter cranking the engine at a

Loading...

Loading...