Section 12: BRAKE AND AIR SYSTEM

PA1553

9

2. Turn the adjustment screw clockwise to

increase the pressure slowly until the re-

quired pressure setting is reached. Tighten

the locking nut.

3. Remove pressure gauge and replace dust

cap on the air pressure check valve.

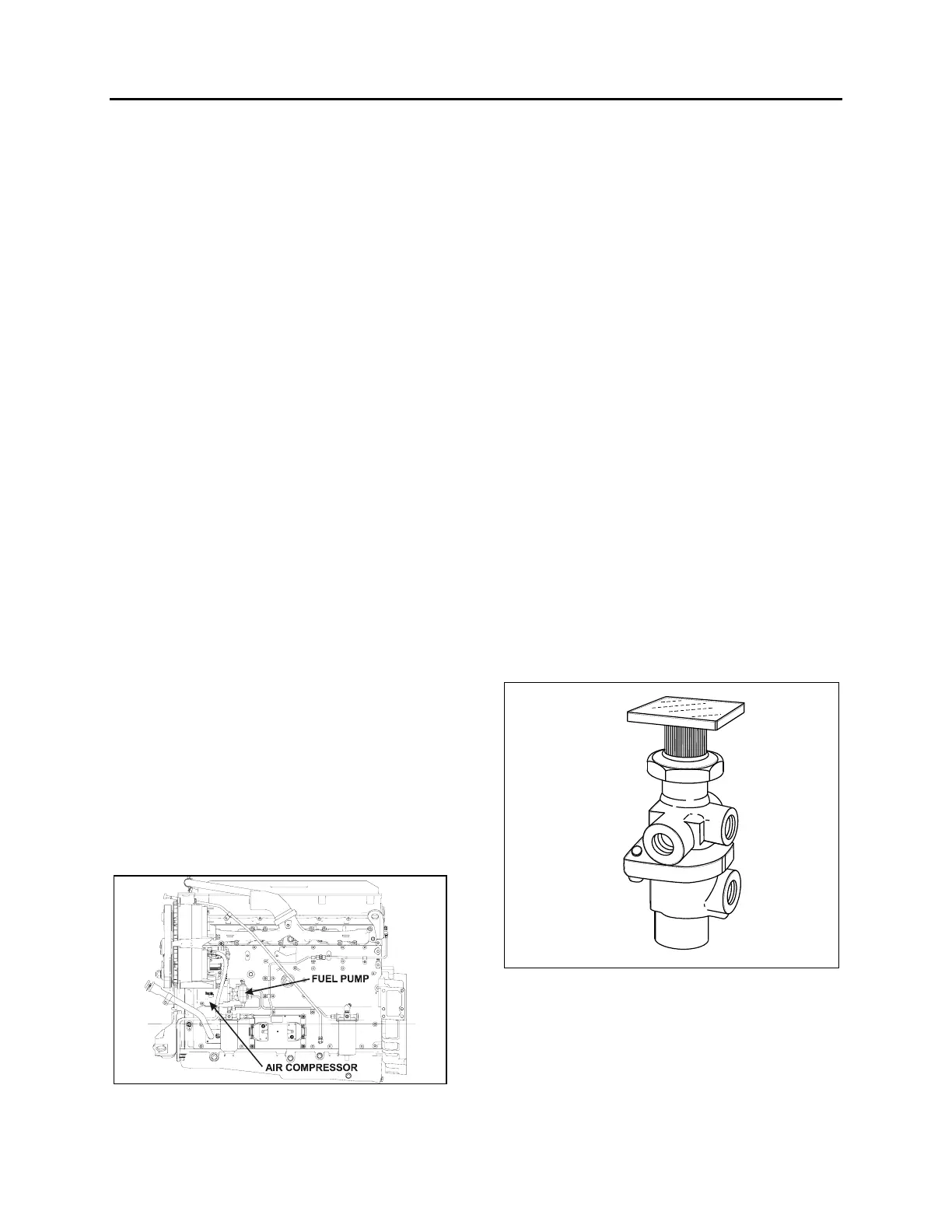

10. AIR COMPRESSOR (BA-921)

The air compressor is located on starter side of

the engine, on the rear of the engine gear case

(Fig. 8). Its function is to provide and maintain

air under pressure to operate devices in brake

and air systems.

This air compressor also drives the engine fuel

pump which is bolted to the rear end of the

compressor. The compressor crankshaft is

designed to accept a drive coupling which is

placed between the compressor and fuel pump.

The compressor is driven by the bull gear, and

is water cooled. Engine coolant is fed to the

compressor through a flexible hose tapped into

the block water jacket and connected to the rear

of the compressor. Coolant returns from the top

of the compressor (governor side) through a

flexible hose to the engine pump.

The air is taken from the air intake manifold and

entered in the top of the compressor. The

compressed air is pushed into the discharge line

located on side of the compressor, which sends

air to the air dryer. Lubricating oil is supplied to

the compressor by a line from the cylinder block

oil gallery connected to the air compressor.

Lubricating oil returns to the engine crankcase

through the air compressor drive assembly.

Maintenance and repair information on the

Bendix BA-921 air compressor is supplied in the

applicable booklet annexed to this section under

reference number SD-01-676.

FIGURE 8: AIR COMPRESSOR LOCATION 03061

10.1 COMPRESSOR REMOVAL AND

INSTALLATION

1. Exhaust compressed air from air system by

opening the drain valve of each air tank.

2. Drain the engine cooling system. See

Section 5: "Cooling System".

3. Identify and disconnect all air, coolant and

oil lines from the compressor assembly.

4. Access the compressor by the engine R.H.

side compartment. Remove the four

compressor mounting bolts and the two fuel

pump support bracket bolts.

5. Slide air compressor rearward to disengage

the hub from coupling. Remove the air

compressor.

Reverse removal procedure for installation.

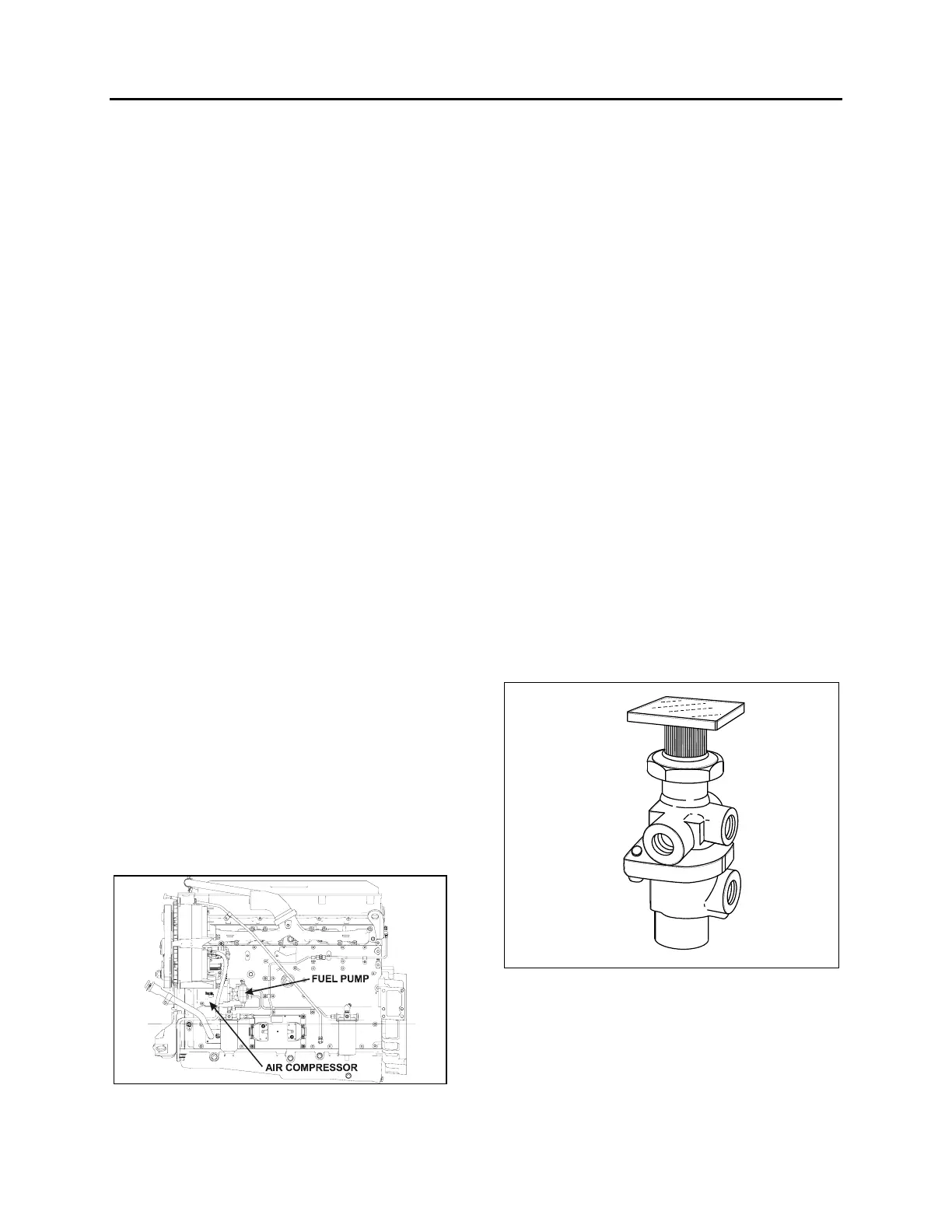

11. EMERGENCY/PARKING BRAKE

CONTROL VALVE (PP-1)

A push-pull control valve mounted on the L.H.

lateral console is provided for parking brake

application or release. The spring brakes are

self-actuated whenever the control valve supply

pressure drops below 40 psi (275 kPa). In the

UP position, brakes are ON. In the DOWN

position, brakes are RELEASED. A protective

case around the knob prevents accidentally

releasing the brakes.

FIGURE 9: PP-1

12142

Maintenance and repair information on this valve

is supplied in the applicable booklet annexed to

this section under reference number

SD-03-3611.

Remove the valve the following way:

1. Drain the air system.

Loading...

Loading...