Section 12: BRAKE AND AIR SYSTEM

PA1553

14

since all pads are the same. Once removed,

worn pads should be replaced in their original

position.

FIGURE 21: BRAKE PAD CHECK 12117

25.1.2 Caliper Maintenance

Use the following procedure for brake calipers

servicing. The procedure must be followed in

proper sequence to ensure that only needed

repairs or replacements are performed on

calipers. Problems such as hot brakes or

cracked rotors may be effects of sticking

calipers, too-small clearance between rotor and

pad or possible trapped air pressure in the brake

chamber. If any of these symptoms occur,

perform this procedure before replacing the rotor

to ensure the cause of the problem is properly

solved.

1. Check for presence of residual pressure:

To check if there is any residual air pressure in

the brake chamber, make four or five brake

applications, then try to turn the wheel manually,

if the wheel does not turn, use a wrench to crack

the air line and listen for trapped air in the brake

chamber then try to turn the wheel manually

again. If you find trapped air in the brake

booster, ensure that all pneumatic components

in the braking system are functioning properly.

NOTE

A residual pressure of 2-3 PSI in the system is

sufficient to prevent the brakes from releasing.

Also the stop light switch can operate with as

little as 1 PSI, therefore an illuminated brake

light does not mean brakes are dragging.

2. Pad to rotor clearance inspection:

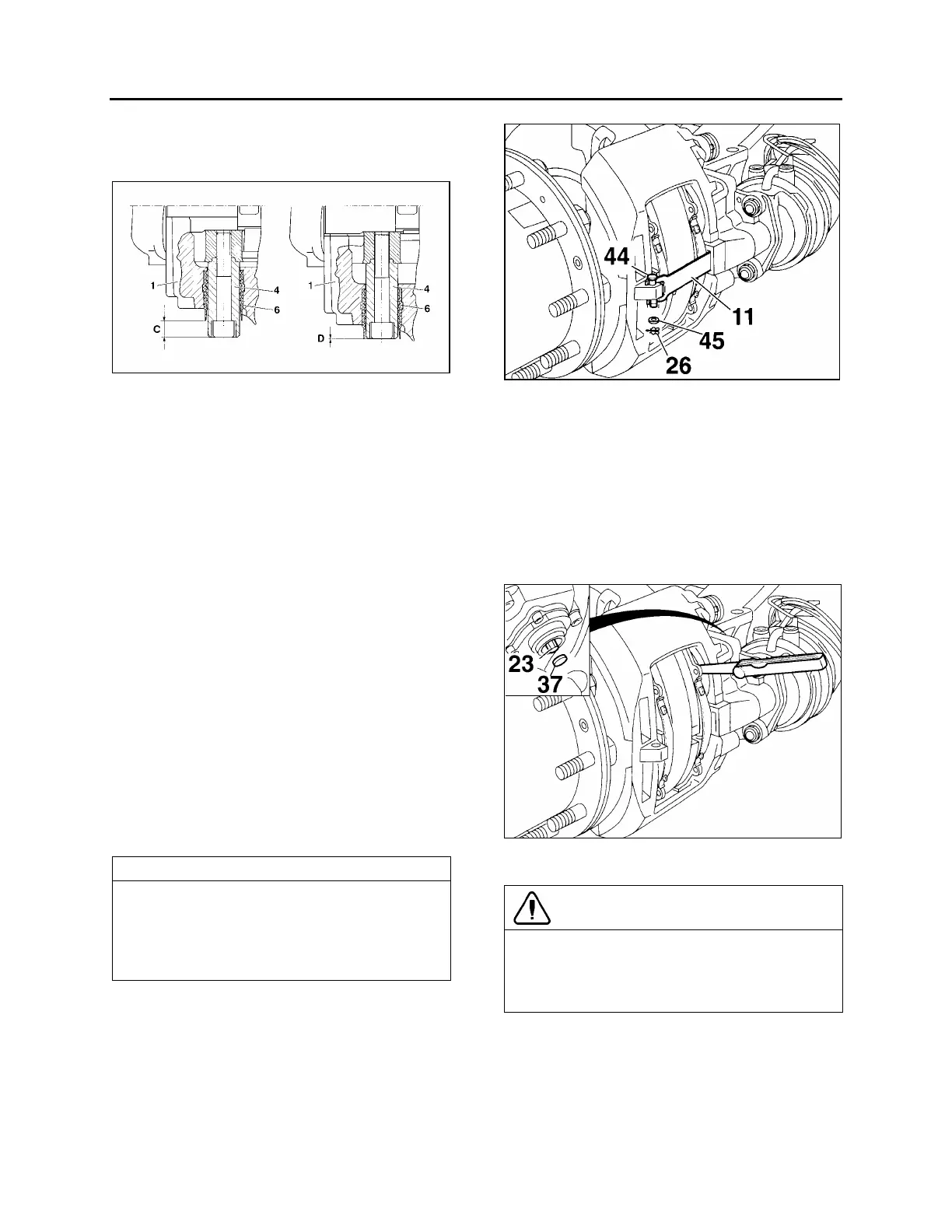

Remove clip and washer (26 & 45, Fig. 22),

push down retainer bar (11), pull out pin (44)

and remove retainer bar. Push caliper toward

actuator (center of vehicle) for maximum

clearance.

FIGURE 22: CLEARANCE INSPECTION 12119

3. Measure pad to rotor clearance:

Place a long feeler gauge (long enough to

measure across entire tappet surface) between

the tappet and the backing plate of the pad,

measure clearance at both tappets. Clearance

should range between 0.020 and 0.035 inch (0.5

mm and 0.9 mm), with a maximum difference

between tappet measurements on same brake

of 0.008 inch (0.2 mm).

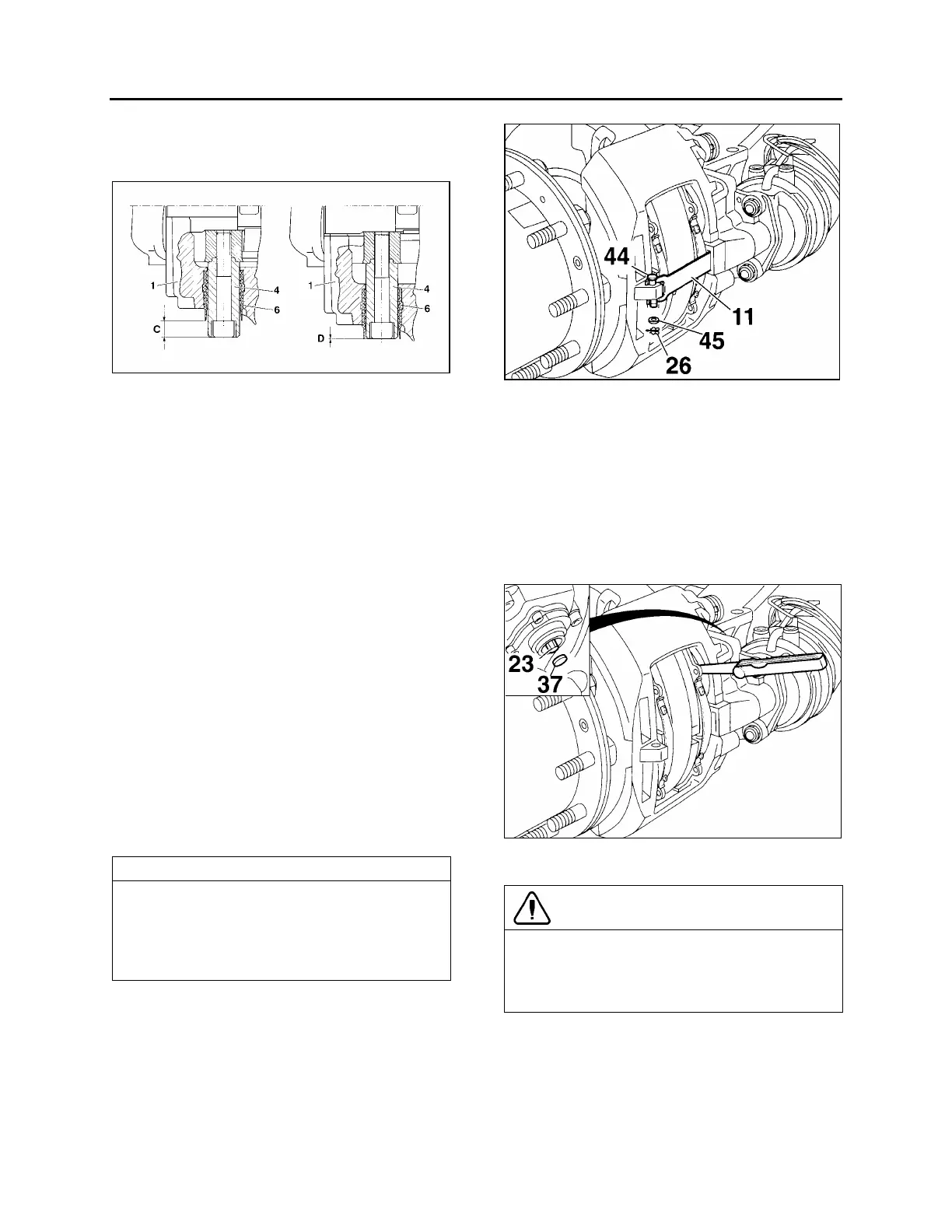

FIGURE 23: RUNNING CLEARANCE 12116

4. Checking the adjuster

CAUTION

Use only a standard box wrench on the

adjuster hexagonal pinion. Do not overtorque

the pinion as overtorquing will damage the

pinion.

a) Remove cap (37, Fig. 23).

b) Using a box wrench (8 mm), turn the

adjuster pinion (23, Fig. 23) counterclock-

wise about 2 - 3 clicks to increase running

clearance. By operating the braking system

Loading...

Loading...