Section 11: REAR AXLES

PA1553

7

NOTE

Refer to Section 16, "Suspension", for proper

torque tightening of the longitudinal radius rod

support nuts.

NOTE

When the drive alignment is changed, the tag

alignment must also be adjusted.

1.12 AXLE SHAFT SEALING METHOD

The following method is to be used to ensure

that axle shaft installation is fluid-tight:

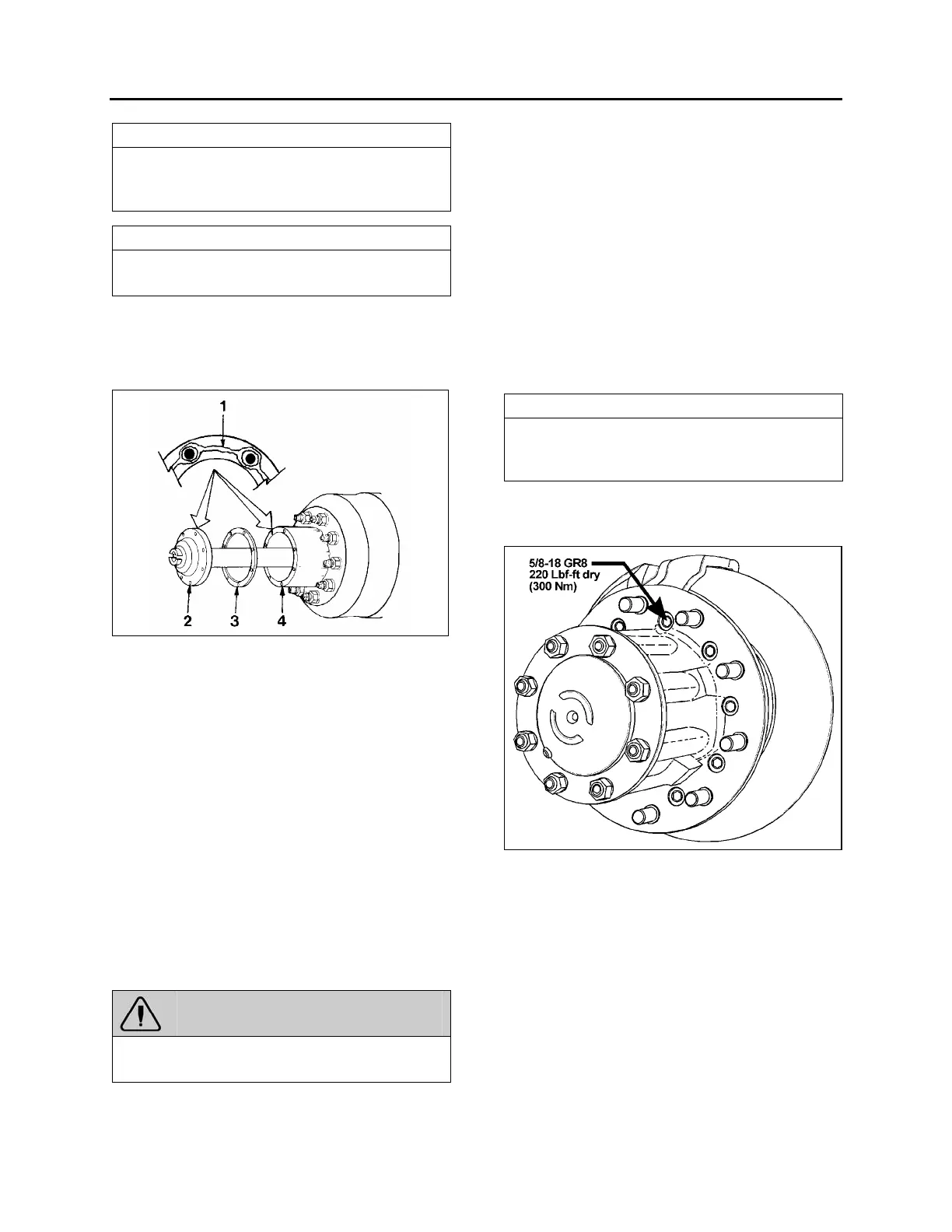

FIGURE 9: AXLE SHAFT INSTALLATION 11003

1 ................................................... Silicone sealant*

2 .............................................................. Axle shaft

3 ...................................................................Gasket

4 .............................................................Wheel hub

1. Clean the mounting surfaces of both the axle

shaft flange and wheel hub where silicone

sealant will be applied. Remove all old

silicone sealant, oil, grease, dirt and moisture.

Dry both surfaces.

2. Apply a continuous thin bead of silicone

sealant* (Prévost P/N 680053) on the

mounting surfaces and around the edge of all

fastener holes of both the axle shaft flange

and wheel hub.

*

GENERAL ELECTRIC Silicone Rubber Adhesive Sealant

RTV 103 Black.

WARNING

Carefully read cautions and instructions on the

tube of silicone sealant and its packing.

3. Assemble components immediately to permit

the silicone sealant to compress evenly

between parts.

a. Place a new gasket, then install the axle

shaft into the wheel hub and differential

carrier. The gasket and flange of the axle

shaft must fit flat against the wheel hub.

b. Install the tapered dowels at each stud

and into the flange of the axle shaft. Use

a punch or drift and hammer if needed.

c. Install the lock washers and nuts on the

studs. Tighten nuts to the correct torque

value.

NOTE

Torque values are for fasteners that have a

light application of oil on the threads (refer to

Meritor Maintenance Manual).

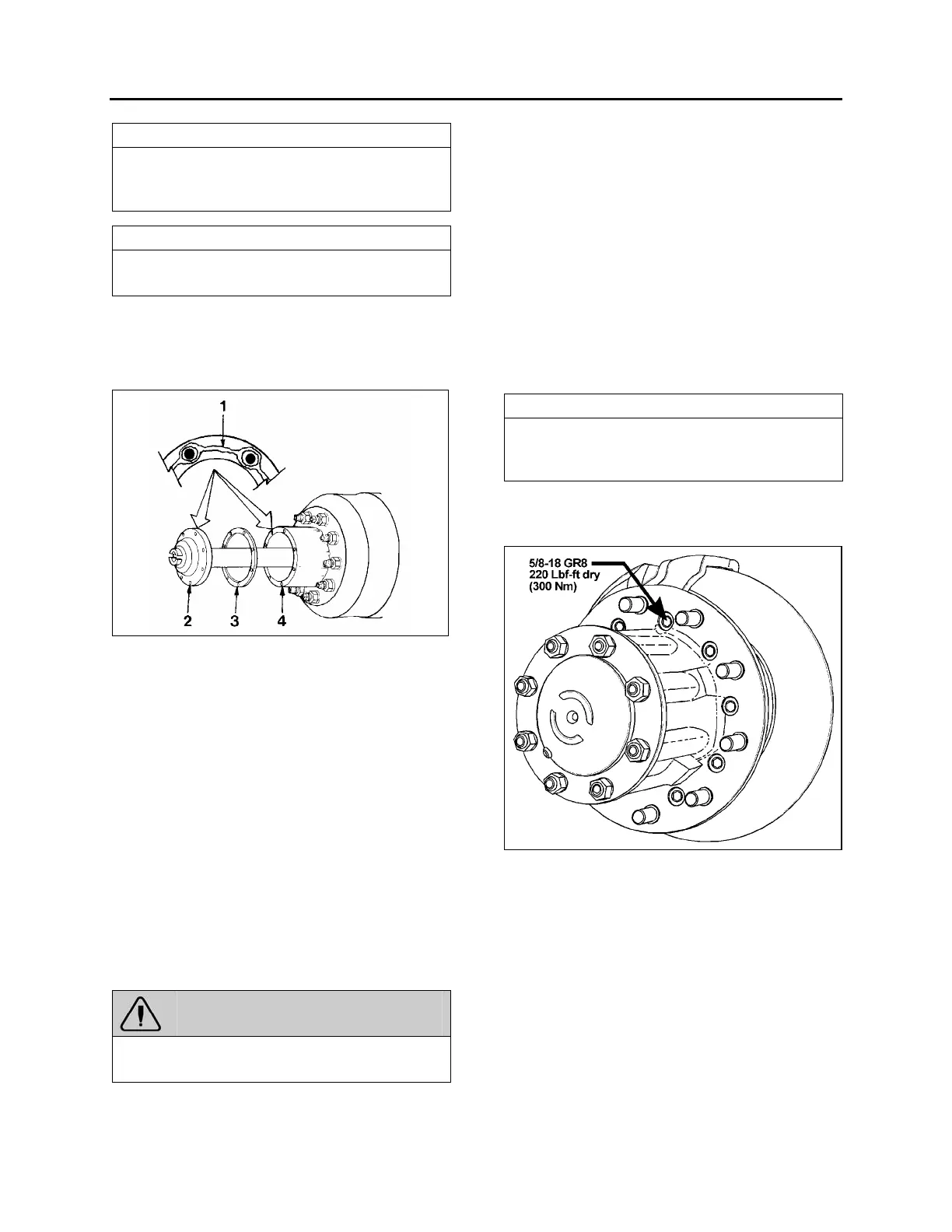

9/16-18 plain nut: 110 - 165 lbf-ft (149 -224 Nm)

5/8-18 plain nut: 150 - 230 lbf-ft (203 - 312 Nm)

FIGURE 10: TORQUE SPECIFICATION 11030

2. TAG AXLE

The tag axle is located behind the drive axle. It

carries a single wheel and tire on each side.

2.1 RETRACTING TAG AXLE

The standard tag axle retraction system is

controlled by a valve located on the right lateral

console and enables unloading and raising the

tag axle (refer to the "OWNER'S MANUAL" for

location of controls). This system has been

designed for the following purposes:

Loading...

Loading...