Section 12: BRAKE AND AIR SYSTEM

PA1553

17

NOTE

Do not attempt to use thinner or alcohol to

clean the pin without removing it as it may

damage the rubber bushing.

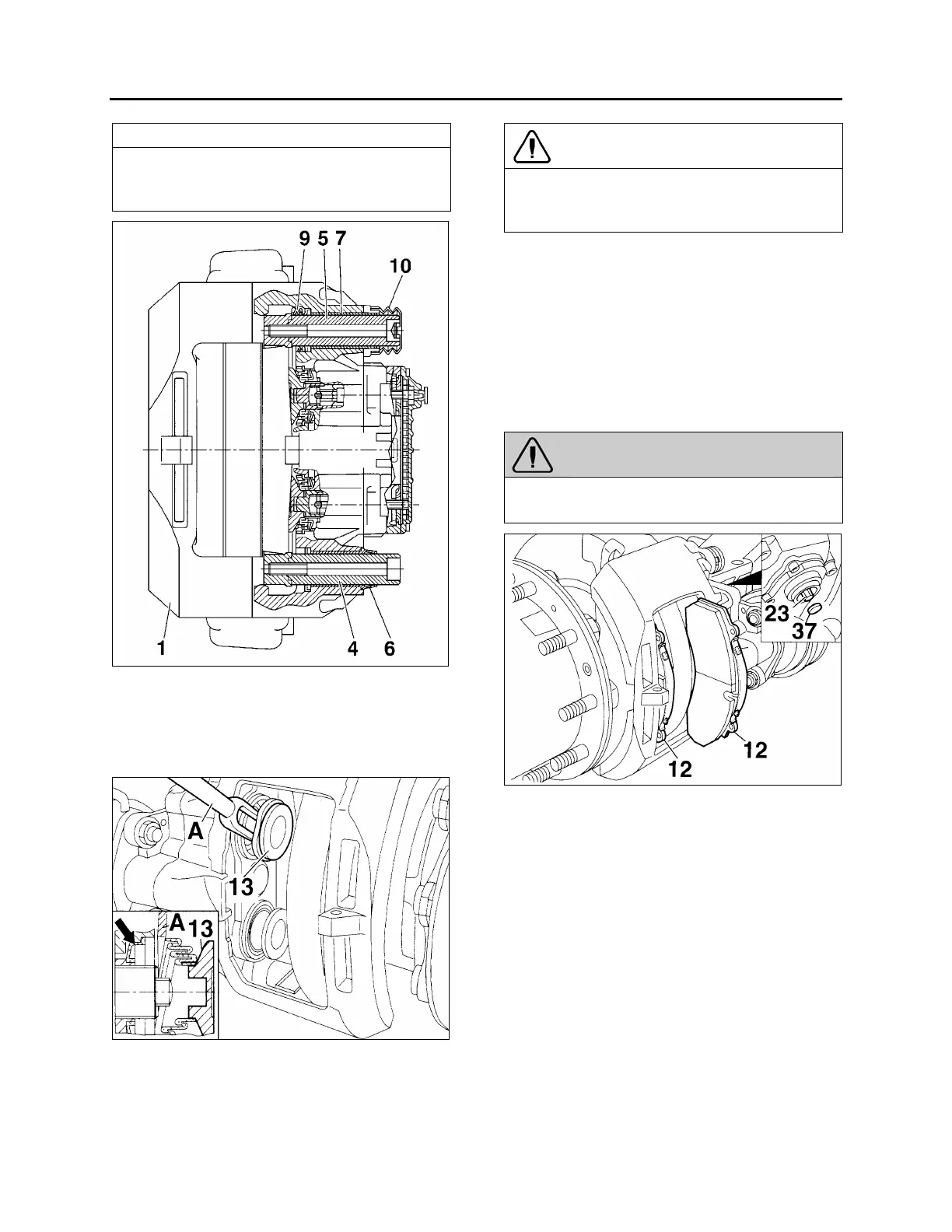

FIGURE 31: CALIPER GUIDANCE 12114

25.1.8 Checking the Tappet Boots

a) The rubber boots (13, Fig. 32) should show

no damage, check the attachment.

FIGURE 32: RUBBER BOOTS

12115

CAUTION

Any ingress of water and dirt will lead to

corrosion and may affect the function of the

actuation mechanism and adjuster unit.

b) If boots are damaged but show no

corrosion, the boots and tappets should be

replaced (Prévost #611177).

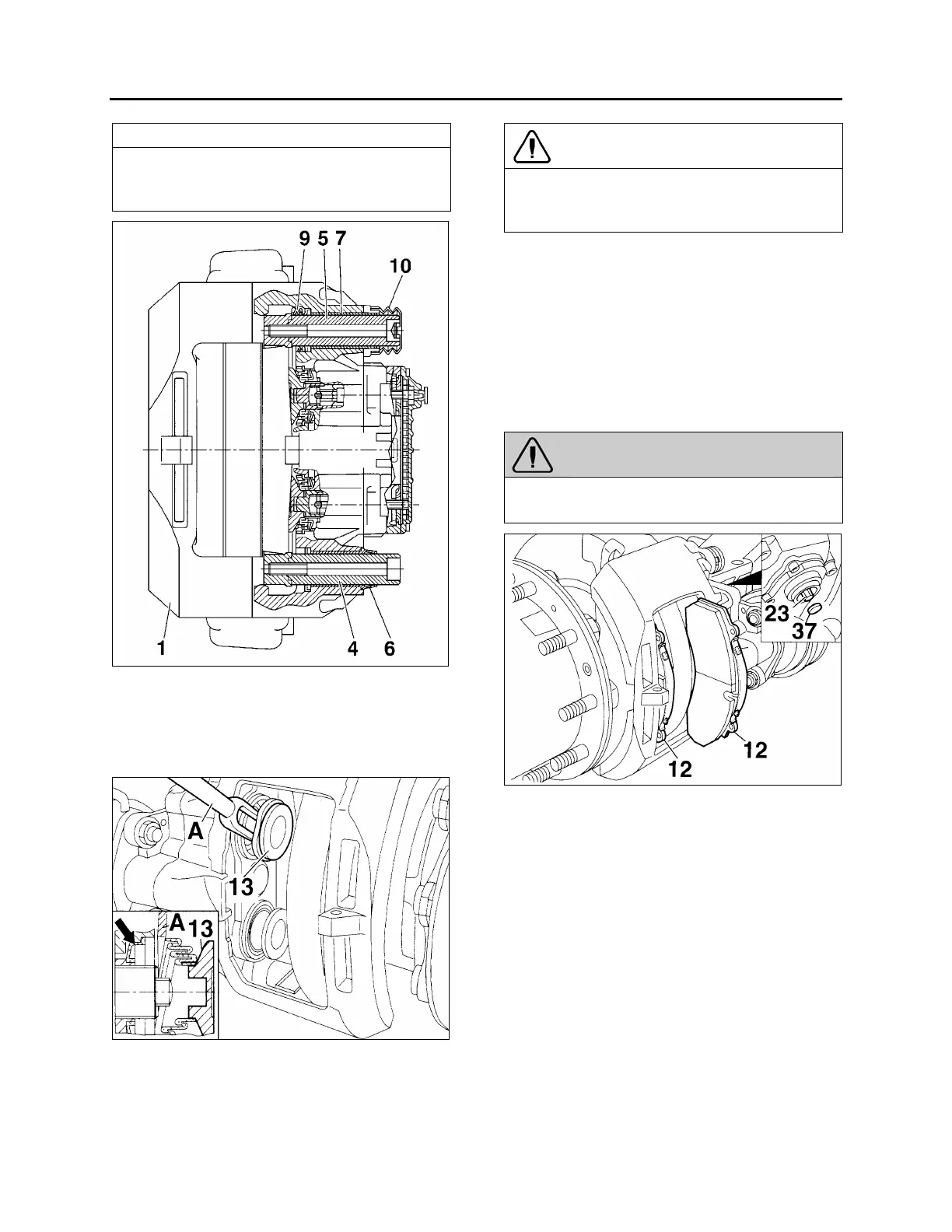

25.1.9 Pad Installation

Turn adjuster pinion (23, Fig. 33) counterclock-

wise until tappets are fully retracted and clean

pad seat area. Slide caliper to full outboard

position and install outside pad. Slide caliper to

full inboard position and install inside pad.

WARNING

It is recommended to change all pads on an

axle at the same time.

FIGURE 33: PAD INSTALLATION 12111

25.1.10 Adjusting the Running Clearance

a) Insert a feeler gauge 0.028 inch (0.7 mm

thickness) between tappet and pad backplate

(Fig. 34). Turn adjuster pinion clockwise until

0.028 inch (0.7 mm) clearance is achieved.

Replace cap (37) (Prévost # 641313).

b) To ensure a constant running clearance

between the rotor and pads, the brake is

equipped with an automatic adjuster unit.

When the pads and rotor wear, the running

clearance between the pads and rotor

increases. The adjuster (23, Fig. 34) and

turning device turn the threaded tubes by the

amount necessary to compensate the wear.

Loading...

Loading...