Section 22: HEATING AND AIR CONDITIONING

PA1553

39

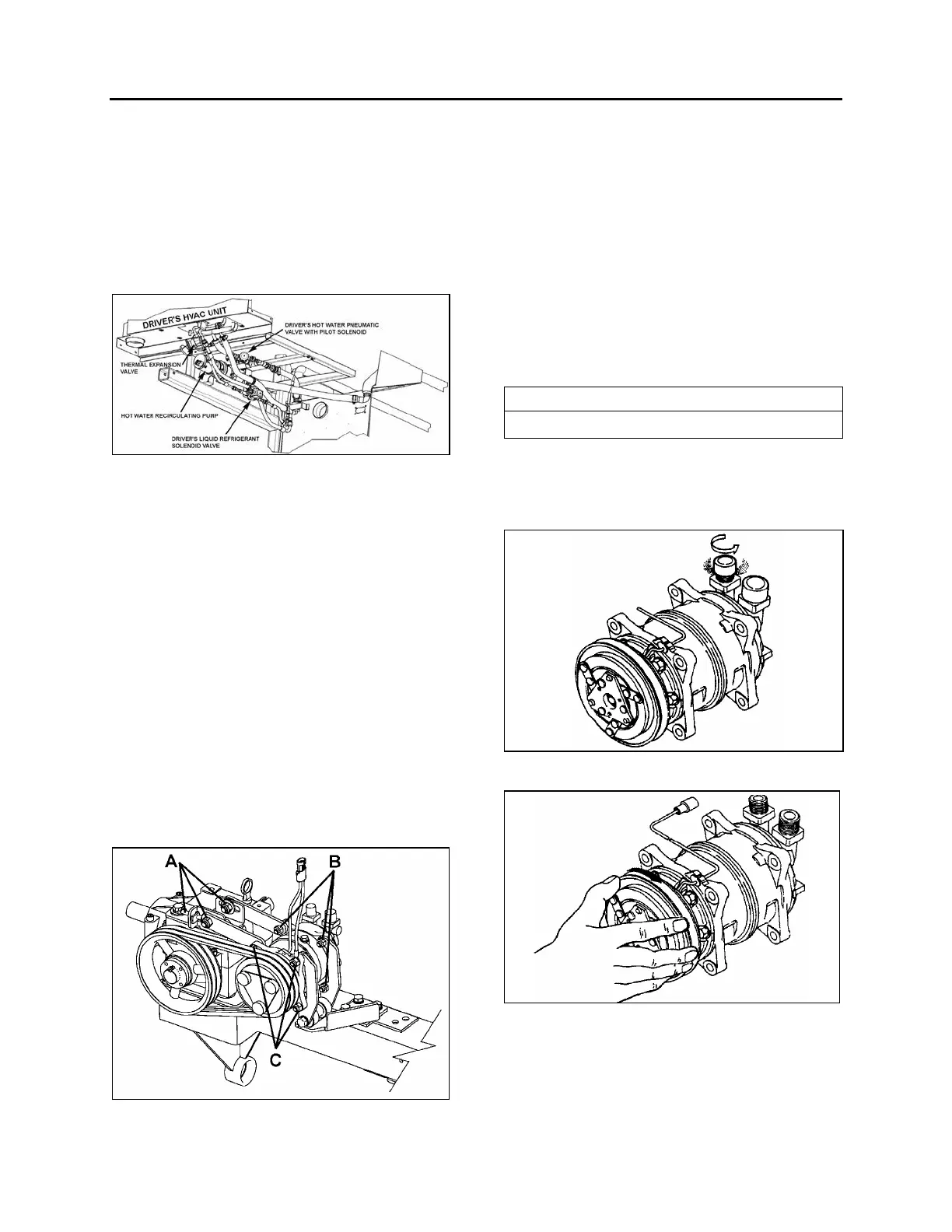

For complete system recovery, any of the High

and Low service ports can be used (Refer to fig.

38, 42 & 43). Energize liquid refrigerant solenoid

valve and measure the quantity of oil recovered.

For the compressor only, use the service valve

port and close the valves. The service valves

open permits full flow of refrigerant to service

port. Service valve closed permits flow of

refrigerant from compressor to service port.

FIGURE 38: SMALL HVAC SYSTEM FRONT

COMPONENTS

10.3.5 Compressor Handling

Do not strike, drop or turn the compressor

upside down. If the compressor is knocked over

or turned upside down, rotate the compressor’s

magnetic clutch 5 to 6 times by hand to circulate

the oil which has settled in the cylinder. Sudden

rotation with oil in the cylinder can cause valve

damage and adversely affect durability.

10.4 COMPRESSOR REMOVAL

10.4.1 When the compressor is operational

* Perform the “OIL RETURN OPERATION”

(Refer to paragraph 10.9).

10.4.2 When the compressor is inoperable

* Perform the “Refrigerant Recovery”

operation (Refer to paragraph 10.3.4).

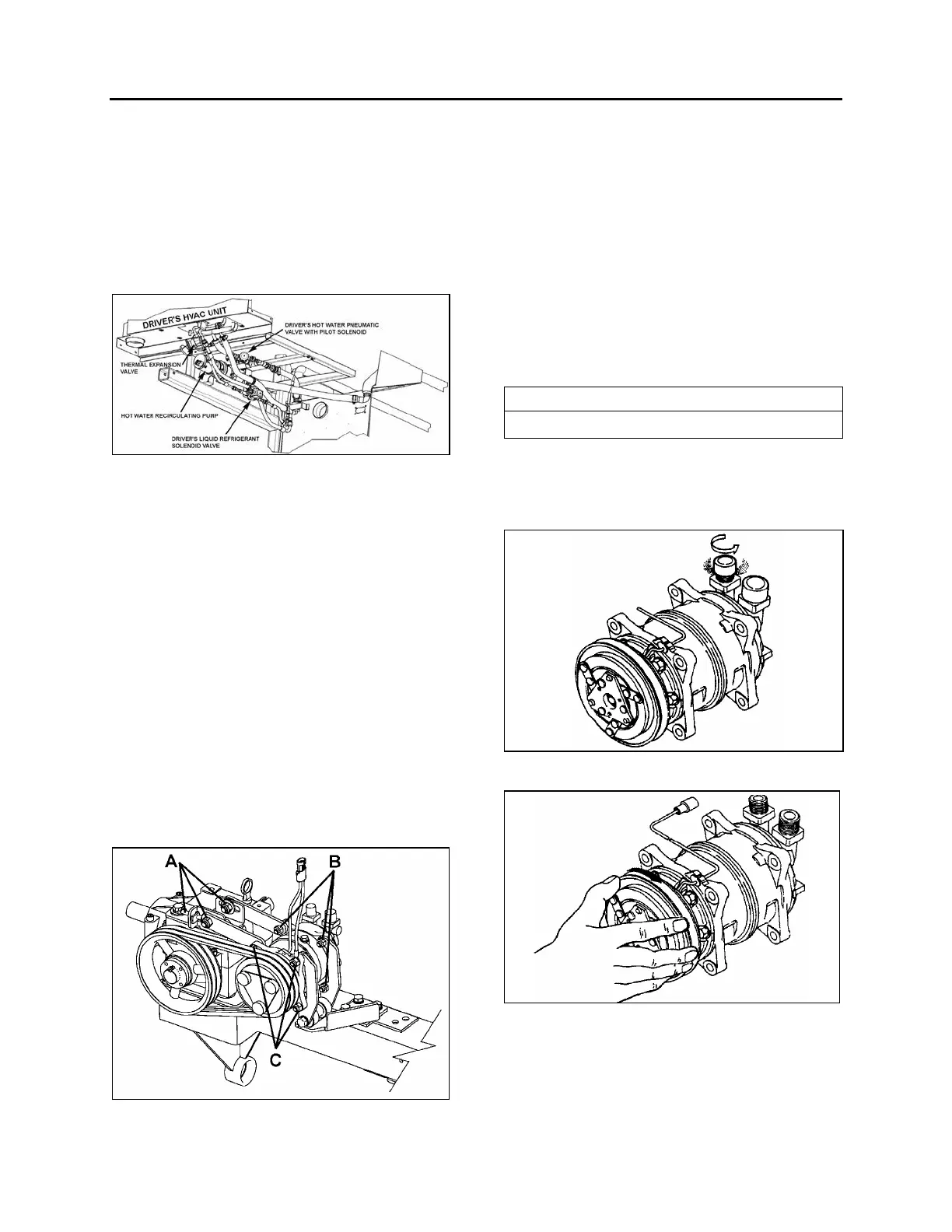

FIGURE 39: COMPRESSOR REMOVAL OR

INSTALLATION

22285

* Slacken bolts A (Refer to figure 39).

* Remove bolts B & C (Refer to figure 39).

* Remove the compressor.

10.5 INSTALLATION PRECAUTIONS

The new compressor is filled with the specified

quantity of compressor oil and nitrogen gas (N²).

When mounting the compressor on the vehicle,

take the following steps:

* Loosen the discharge side connector’s cap

and gently release N² from compressor

(Refer to figure 40).

NOTE

Take care not to let the oil escape.

* Slowly rotate the compressor’s magnetic

clutch several times by hand to distribute the

oil which has settled in the cylinders (Refer

to figure 41).

FIGURE 40: LOOSENING THE DISCHARGE SIDE

CONNECTOR'S CAP

FIGURE 41: ROTATING MAGNETIC CLUTCH

* When using the old compressor in the

system, the compressor should be installed

after changing the oil.

Loading...

Loading...