Section 22: HEATING AND AIR CONDITIONING

PA1553

22

NOTE

Both belts must always be replaced

simultaneously to ensure an equal distribution

of load on each of them.

NOTE

For proper operation of the air bellows, adjust

the upper tensioning bracket to provide a ¼

inch (7 mm) gap between stopper and bracket

with the pneumatic system under normal

pressure and the air pressure regulator set as

per paragraph #3 (Fig. 19).

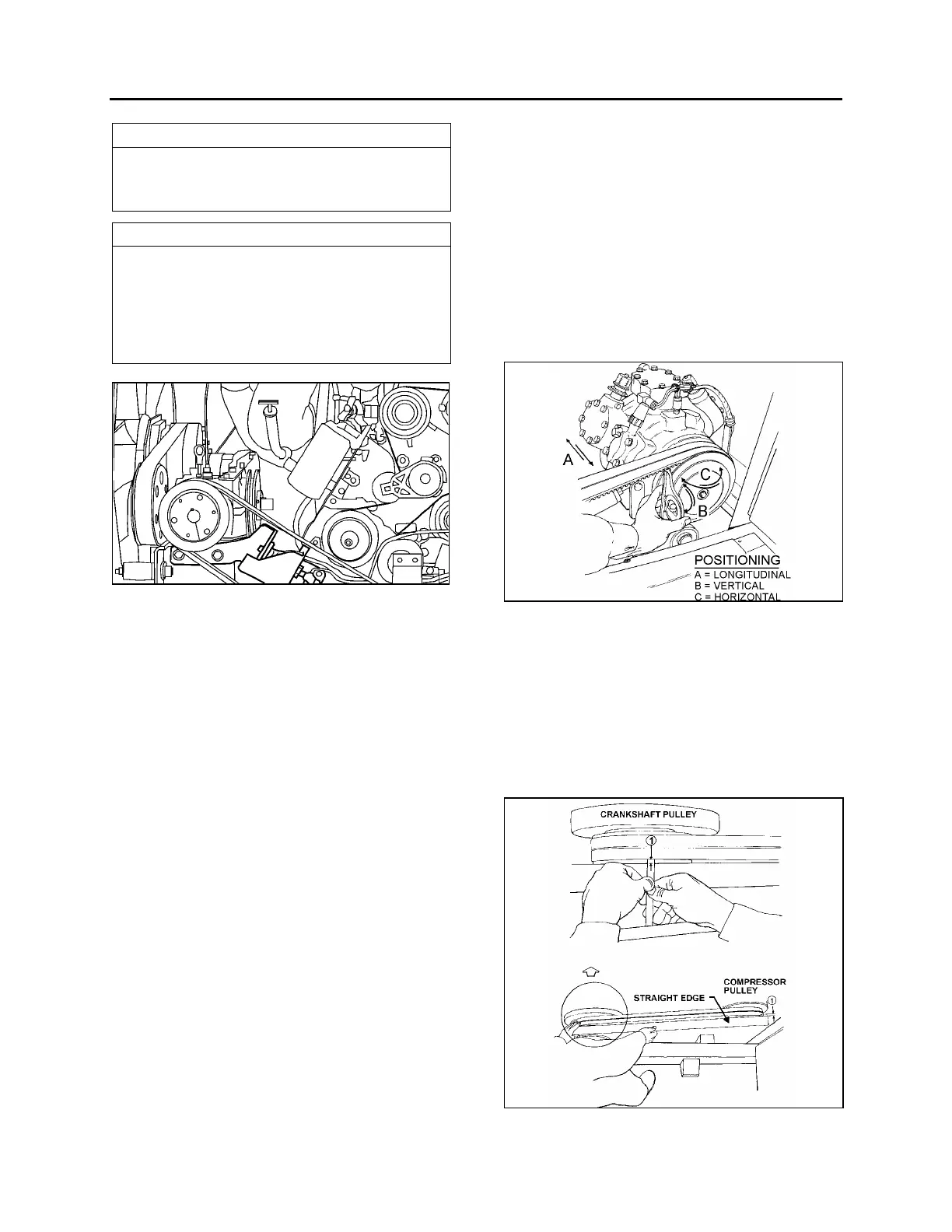

FIGURE 19: BELT TENSIONER 01059

9.1.2 Pulley Alignment

In order to avoid skipping, disengagement and a

premature wear of compressor belt, it is

necessary to align compressor pulley with the

crankshaft pulley. Before performing the

following procedure, release air from belt

tensioners by means of the air pressure

releasing valve. After completing these

procedures reset belt tensioner air pressure

regulator to 45 psi (310 kPa).

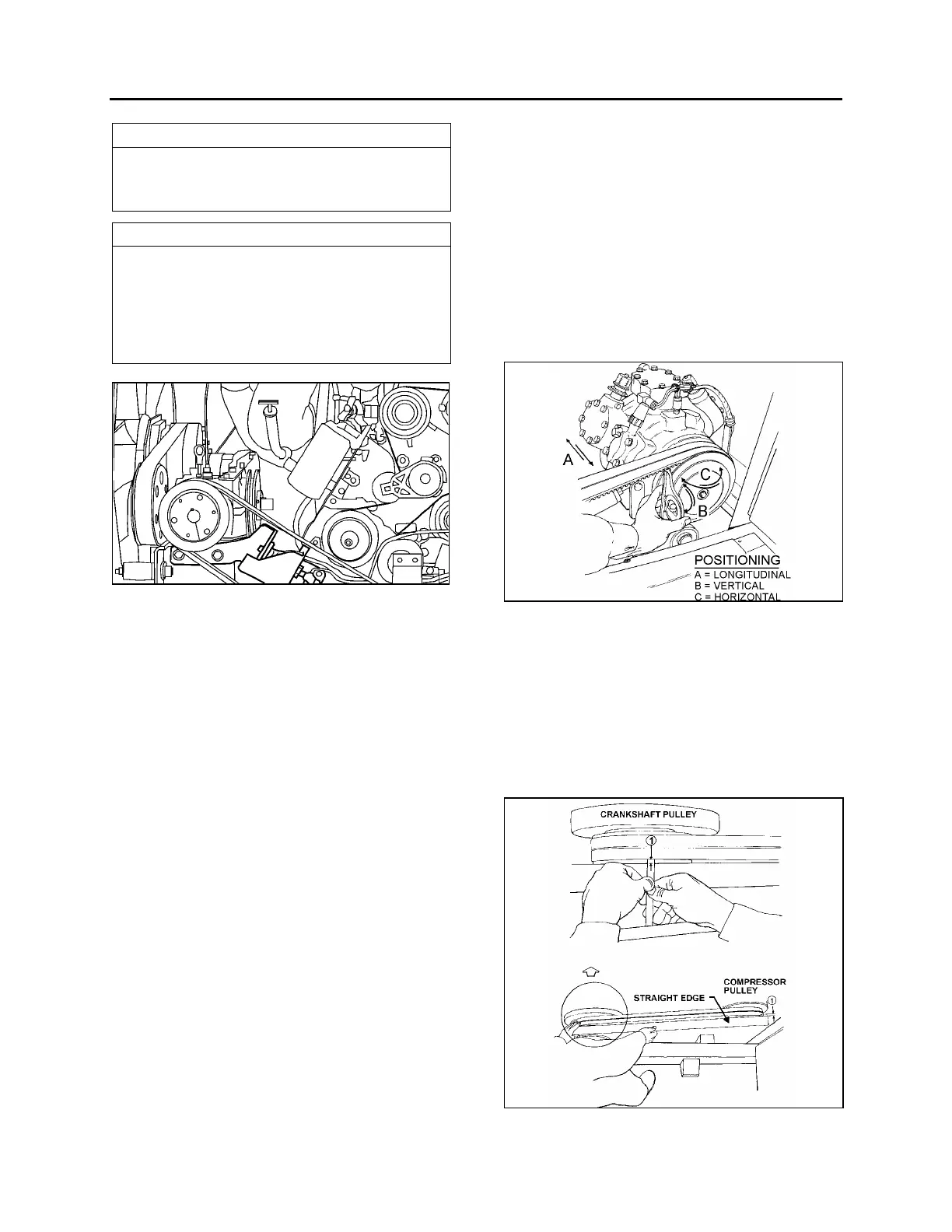

9.1.3 Longitudinal Compressor Alignment

1. Rest an extremity of a straight edge of

approximately 46 inches (117 cm) against

the upper part of the outer face of crankshaft

pulley, positioning the other end close to the

compressor clutch pulley (Figs. 20 & 21).

2. Check the distance between each extremity

of straight edge (1. Fig. 21) and the first

drive belt. If they are different, loosen the

compressor support bolts and with a

hammer, knock support to slide it in order to

obtain the same distance; then tighten bolts.

9.1.4 Horizontal Compressor Alignment

1. Rest an extremity of the straight edge

against the upper part of the outer face of

compressor pulley, positioning the other end

close to the crankshaft pulley.

2. Check the distance between each extremity

of straight edge (1, Fig. 21) and drive belt. If

they are different, loosen the pillow block

compressor bolts and with a hammer, knock

compressor pillow block to slide it, in order

to obtain the same distance; then tighten

bolts.

FIGURE 20: COMPRESSOR ALIGNMENT 22072

9.1.5 Vertical Compressor Alignment

Rest a short "angle and level indicator" on the

outer side face of the crankshaft pulley, adjust

the level indicator inclination at 0

o

and check if

the compressor pulley is at same angle (Figs. 20

& 21). If it is not the same, shim under the

appropriate pillow block in order to obtain the

correct angle.

FIGURE 21: COMPRESSOR ALIGNMENT 22040

Loading...

Loading...