Section 26: XLII SLIDE-OUT

PA1553

27

the panel back side, in order to be able to

stick the new panel in the same way.

6. Check the tape width and use same width

tape when installing new panels.

CAUTION

Make sure the heat gun nozzle tip is at least

4" from surface.

7. Use a heat gun and putty knife to remove

the dried off adhesive and tape residue from

the structure.

DANGER

Because of the adhesive toxicity, never use a

buffer or other sanding method to remove it.

16.4 SIDE PANELS INSTALLATION

NOTE

The side panels are made of aluminum, or of

stainless steel in option. Use rivet of same

material as the panels.

For surface cleaning and preparation, panel

installation and products needed, refer to the

MTH side panel installation procedure described

in section 18: BODY.

1. Protect adjacent surfaces with appropriate

material;

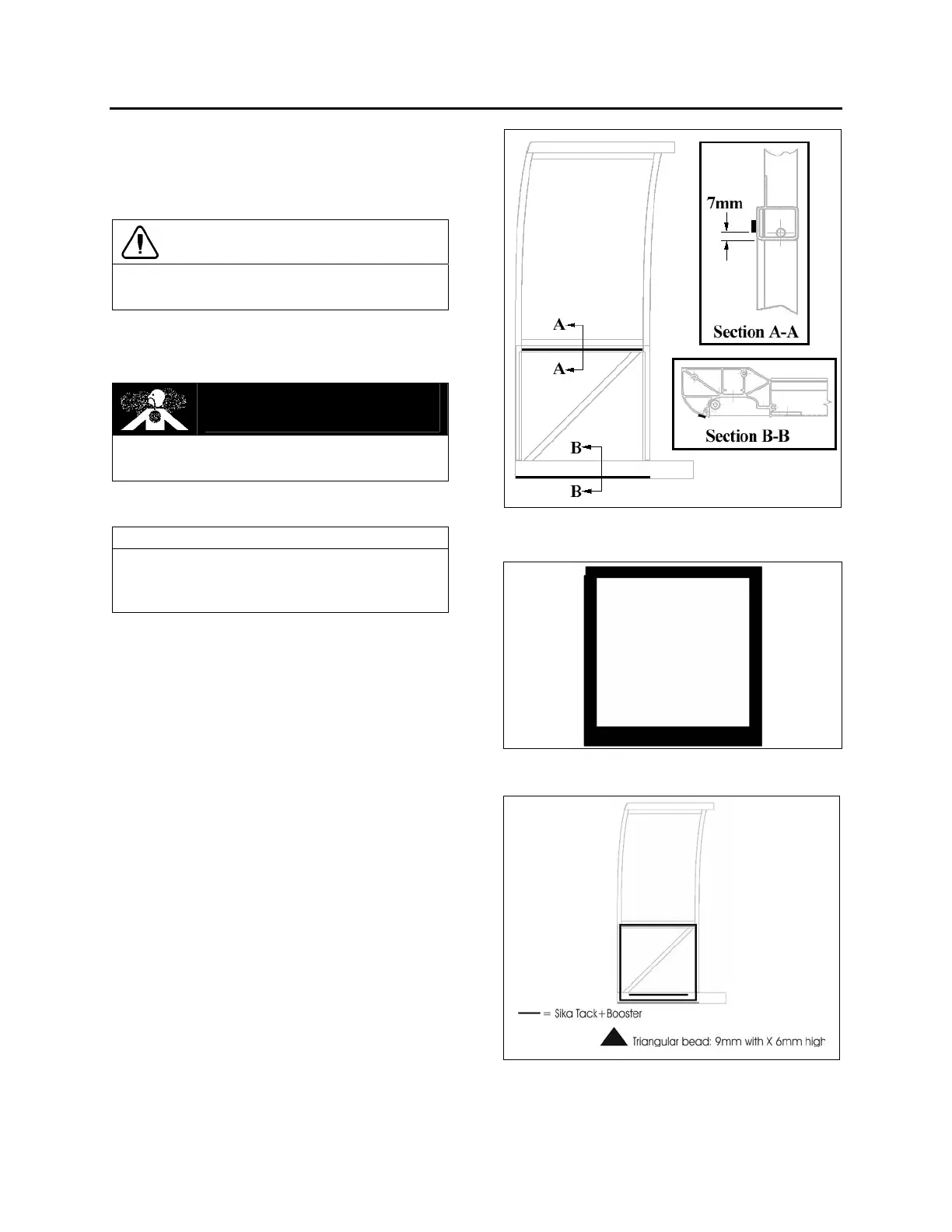

2. Refer to figure 41 for 1/16x1/4 double face

adhesive tape location on structure;

3. Apply Sika 206 G+P on the side panel as

shown in figure

42 ;

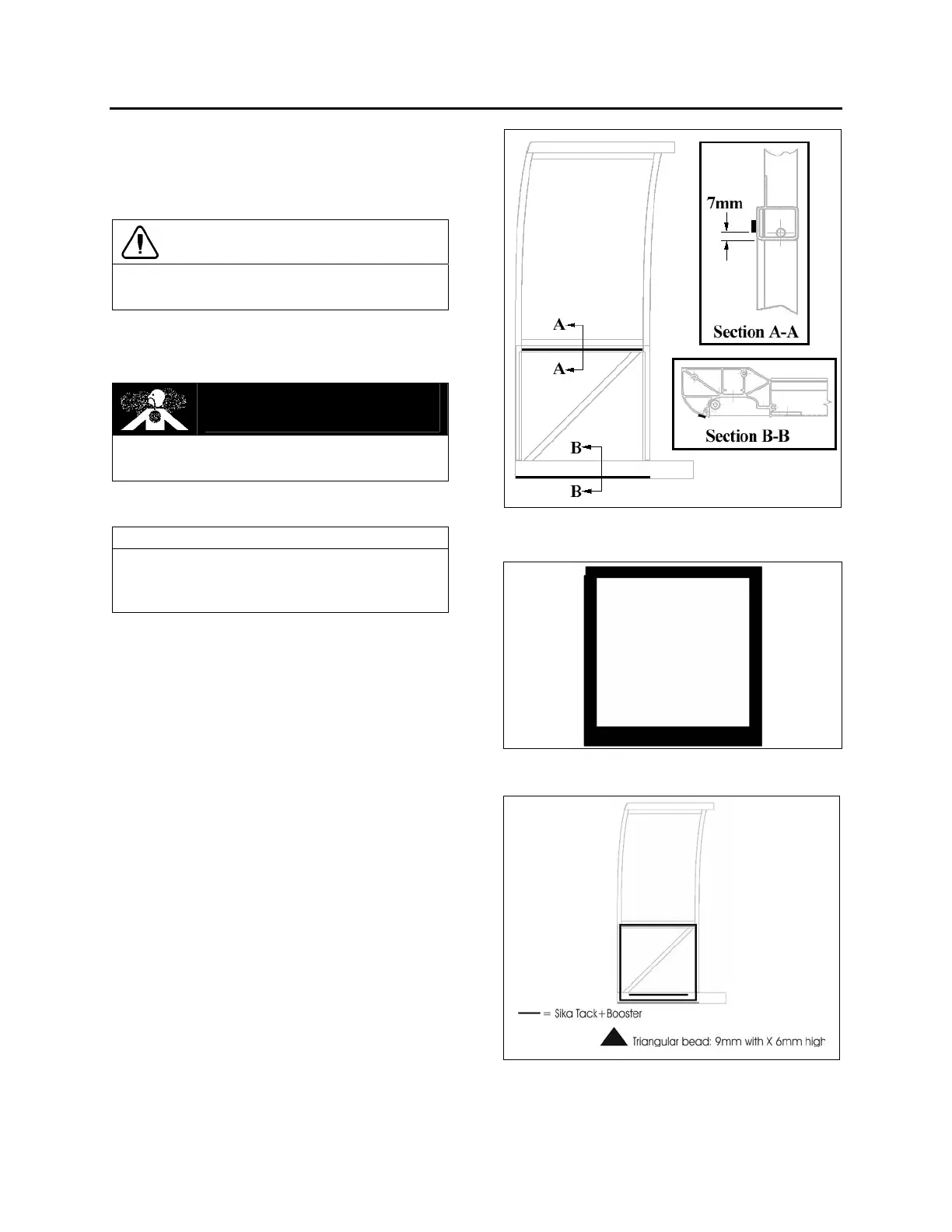

4. Apply Sika Tack+Booster (triangular bead:

9mm width X 6mm high) as shown in Figure

43 and glue panel in place as shown in

FIGURE 44;

5. Exert pressure and let dry for at least 90

minutes;

6. Smooth down the joint and remove glue in

excess;

7. After drying, apply Sika 252 as a finishing

joint;

8. Smooth down the joint.

9. Refer to section 16.11 for the finishing joint

application procedure.

FIGURE 41 : SIDE PANEL INSTALLATION – DOUBLE

FACE ADHESIVE TAPE APPLICATION ON THE SLIDE-

OUT STRUCTURE

FIGURE 42 : SIDE PANEL INSTALLATION – SIKA 206

G+P APPLICATION

FIGURE 43 : SIDE PANEL INSTALLATION – SIKA

TACK+BOOSTER APPLICATION

Loading...

Loading...