Section 12: BRAKE AND AIR SYSTEM

PA1553

10

2. Access this valve by tearing out the finishing

panel, which holds the controls in place

(Fig. 9).

3. Disconnect the air tubes.

4. Remove the retaining screws.

5. Service or replace the valve.

6. Installation is the reverse of removal.

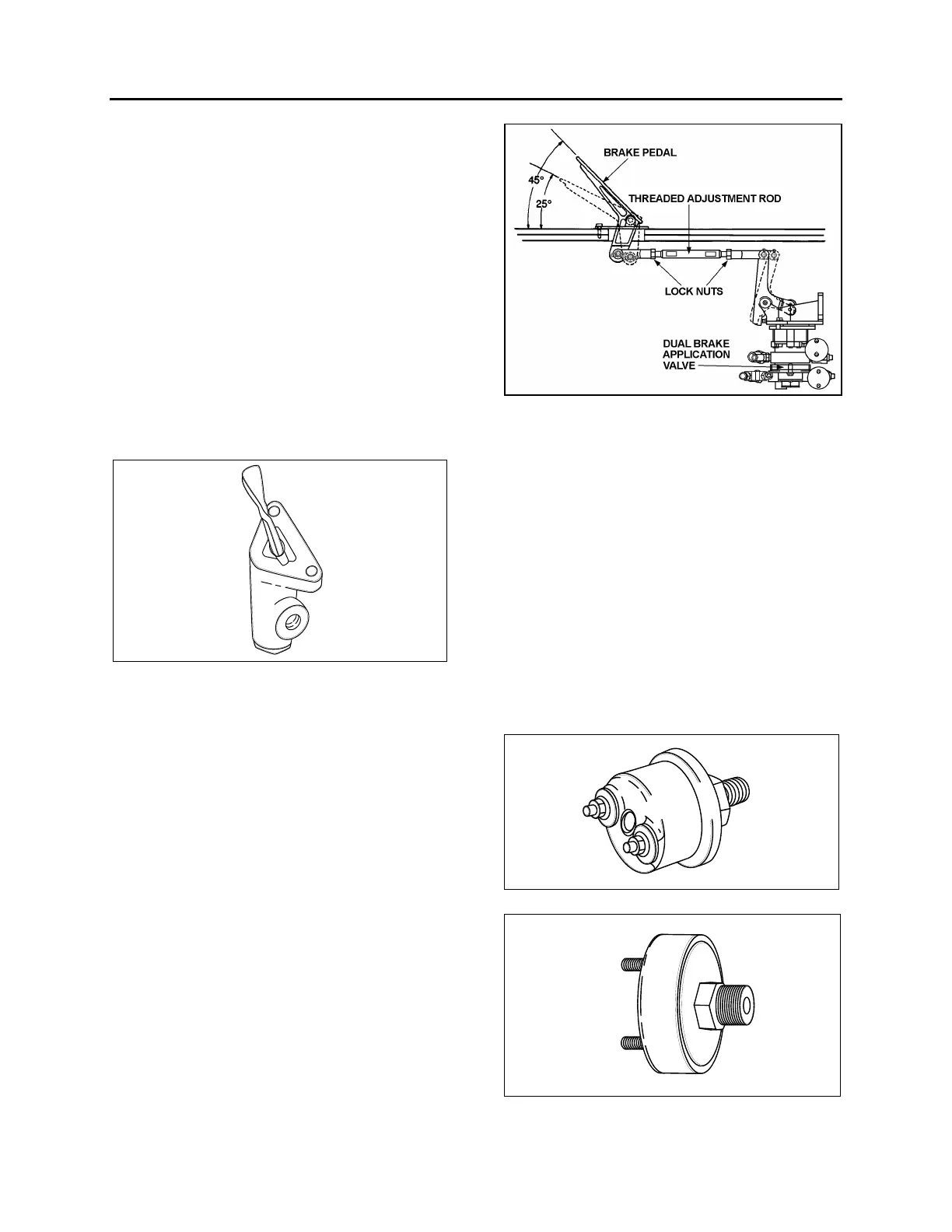

12. FLIP-FLOP CONTROL VALVE (TW-1)

A flip-flop control valve mounted on the L.H.

lateral console is provided to unload and to lift

tag axle air springs. It is a manually operated

"on-off" valve. Maintenance and repair

information on this valve is supplied in the

applicable booklet annexed to this section under

reference number SD-03-3602.

FIGURE 10: TW-1 12138

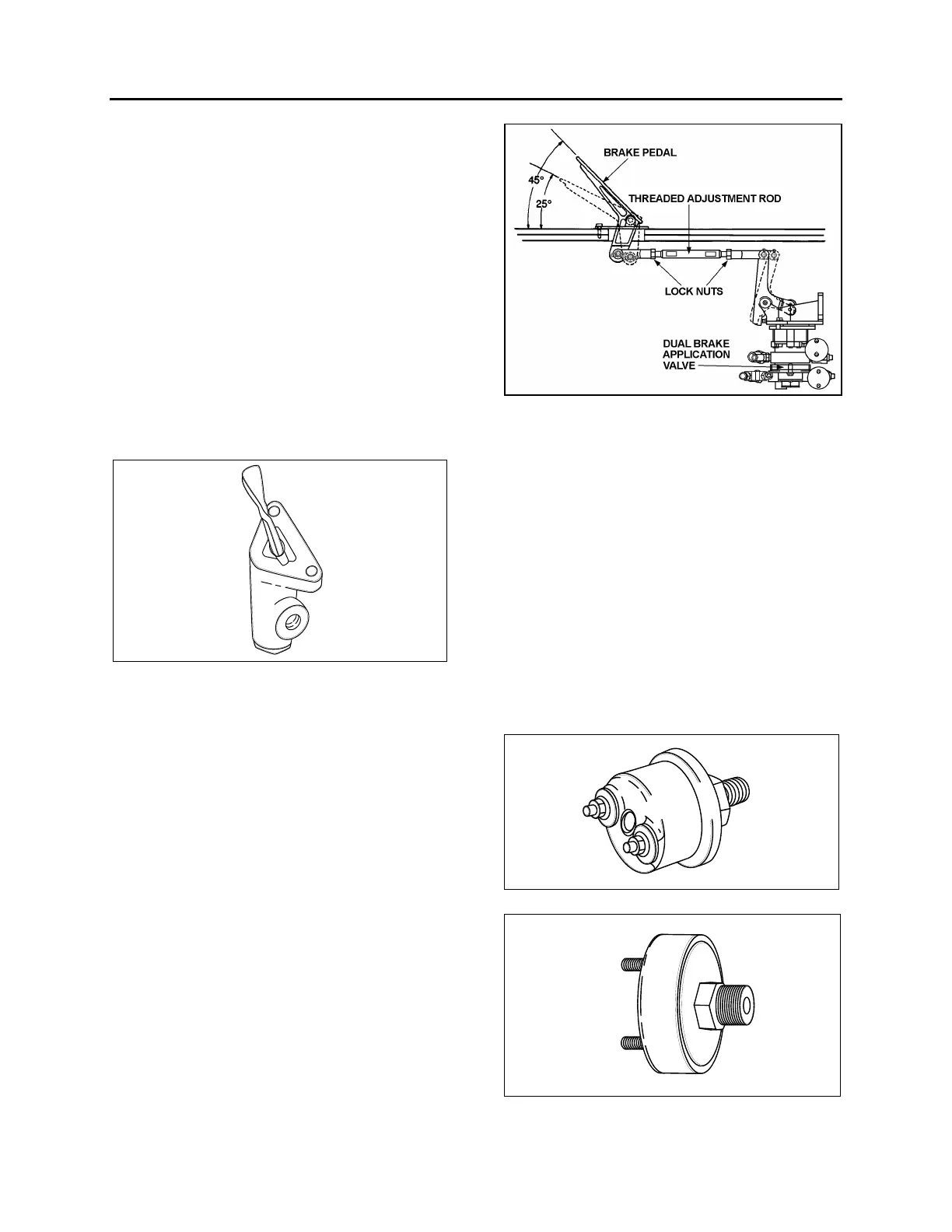

13. DUAL BRAKE APPLICATION VALVE

(E-10P)

The E-10P dual brake valve is a floor mounted,

foot-operated type brake valve with two separate

supply and delivery circuits. This valve is located

in the front service compartment (Fig. 11).

13.1 BRAKE PEDAL ADJUSTMENT

After brake pedal replacement or repair, adjust

the pedal to its proper position according to the

following procedure:

1. Replace the linkage, loosen threaded rod

lock nuts and screw or unscrew the

threaded adjustment rod in order to obtain a

45

o

brake pedal inclination (Fig. 11).

2. Tighten threaded rod lock nuts.

13.1.1 Maintenance

Maintenance and repair information on the E-10P

dual brake application valve is supplied in the

applicable booklet annexed to this section under

reference number SD-03-830.

FIGURE 11: BRAKE PEDAL ADJUSTMENT 12208

14. STOPLIGHT SWITCHES

Two electro-pneumatic stoplight switches are

mounted on the dual brake application valve (E-

12). The upper one is used for the primary air

circuit while the lower one is used for the

secondary air circuit. Both switches are

connected in parallel and have the same

purpose, i.e. completing the electrical circuit and

lighting the stoplights when a brake application

is made. The upper switch (AC Delco) is

designed to close its contact between 2 psi and

4 psi (14 kPa to 28 kPa) (Fig. 12), while the

lower one (Bendix, SL-5) closes its contact at 4

psi (28 kPa) (Fig. 13). The switches are not

serviceable items; if found defective, the

complete unit must be replaced.

FIGURE 12: DELCO SWITCH 12139

FIGURE 13: BENDIX SWITCH 12140

Loading...

Loading...