Section 03: FUEL SYSTEM

PA1553

4

2. FUEL LINES AND FLEXIBLE HOSES

Make a visual check for fuel leaks at all engine-

mounted fuel lines and connections and at the

fuel tank suction and return lines. Since fuel

tanks are susceptible to road hazards, leaks in

this area may best be detected by checking for

accumulation of fuel under the tank. Engine

performance and auxiliary equipment is greatly

dependent on the ability of flexible hoses to

transfer lubricating oil, air, coolant and fuel oil.

Diligent maintenance of hoses is an important

step in ensuring efficient, economical and safe

operation of engine and related equipment.

Check hoses daily as part of the pre-start-up

inspection. Examine hoses for leaks and check

all fittings, clamps and ties carefully. Make sure

that the hoses are not resting on or touching

shafts, couplings, and heated surfaces,

including exhaust manifolds, any sharp edges or

other obviously hazardous areas. Since all

machinery vibrates and moves to a certain

extent, clamps and ties can fatigue with age. To

ensure continued proper support, inspect

fasteners frequently and tighten or replace them

as necessary. Refer to the schematic diagram of

the fuel system (Fig. 1).

CAUTION

Oil level above the dipstick full mark or a

decrease in lube oil consumption may indicate

internal fuel leaks. Check oil level frequently.

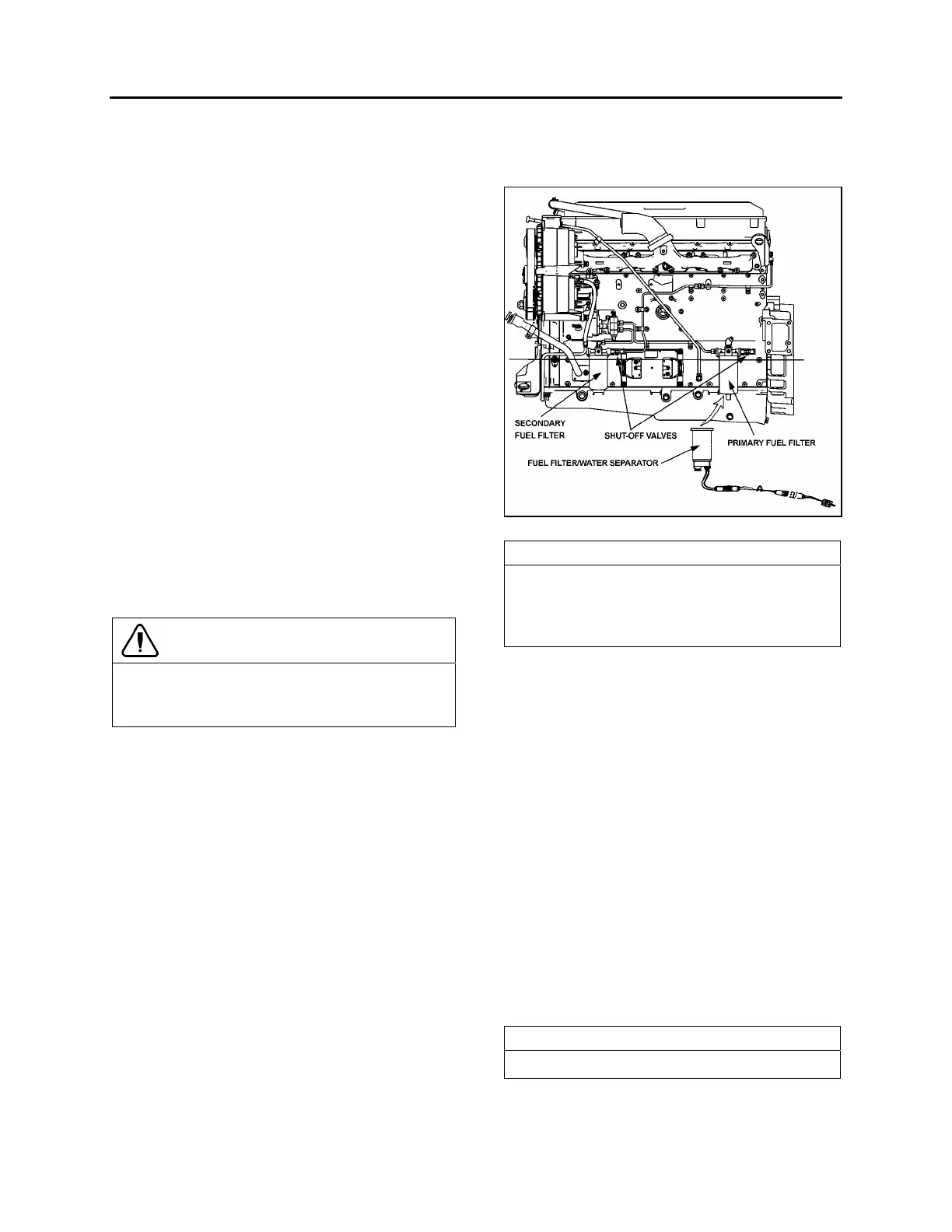

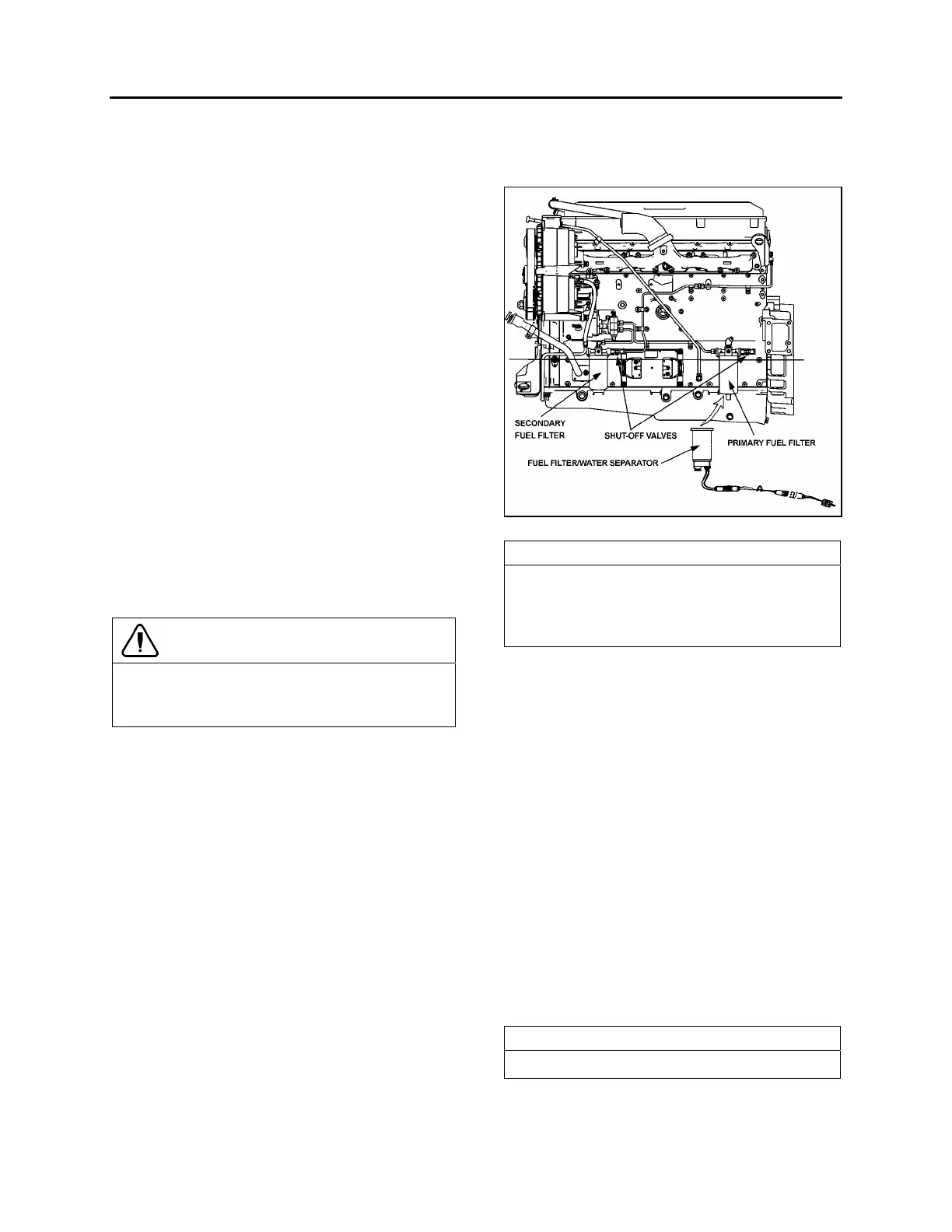

3. FUEL VALVES

Manual shut-off valves on engine fuel-supply

line are located on the R.H. side of engine

compartment (Fig. 2). A manual shut-off valve is

located at the inlet side of the primary fuel filter

(fuel filter/water separator, if vehicle is so

equipped) under the starter. Another manual

shut-off valve is located at the outlet side of the

secondary fuel filter, under the air compressor.

4. FILTERS AND WATER SEPARATOR

The fuel system is equipped with primary and

secondary fuel filters for additional protection of

the injectors. A fuel-filter/water-separator may

be installed in primary fuel-filter location, to

prevent water infiltration in engine fuel system

(Fig. 2). It should be drained periodically, or

when the water separator telltale light on the

dashboard illuminates.

To drain, loosen positive seal drain valve below

separator, and tighten after water has been

flushed out.

FIGURE 2: MANUAL SHUT-OFF VALVES 03060

NOTE

The operating conditions and cleanliness of

type of fuel used determine the service

intervals of the filter/water separator element

and the secondary fuel filter cartridge.

4.1 FUEL FILTER/WATER SEPARATOR

SERVICING

The fuel filter/water separator is located on the

starter side of the engine, below the starter. The

water separator must be drained periodically or

when the telltale light on the dashboard

illuminates.

Replace the water separator element as follows:

1. Drain the fuel filter/water separator as stated

previously.

2. With engine "OFF" and engine fuel supply

line valves closed; remove the filter

element/bowl assembly from cover (for

valve location, see "3. FUEL VALVES" in

this section).

3. Separate bowl from filter element. Clean

bowl and O-ring groove.

NOTE

Bowl is reusable, do not discard.

Loading...

Loading...